Novel non-woven fabric with high bacteriostatic performance and preparation method thereof

A new type of non-woven fabric technology, applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of dissolution loss and limited effect, and achieve the effect of fast antibacterial speed, long shelf life and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

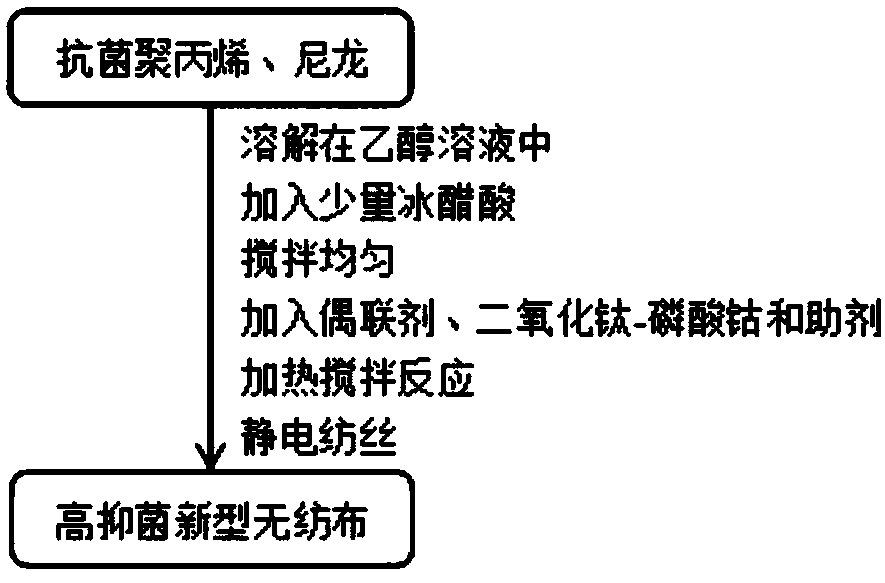

Method used

Image

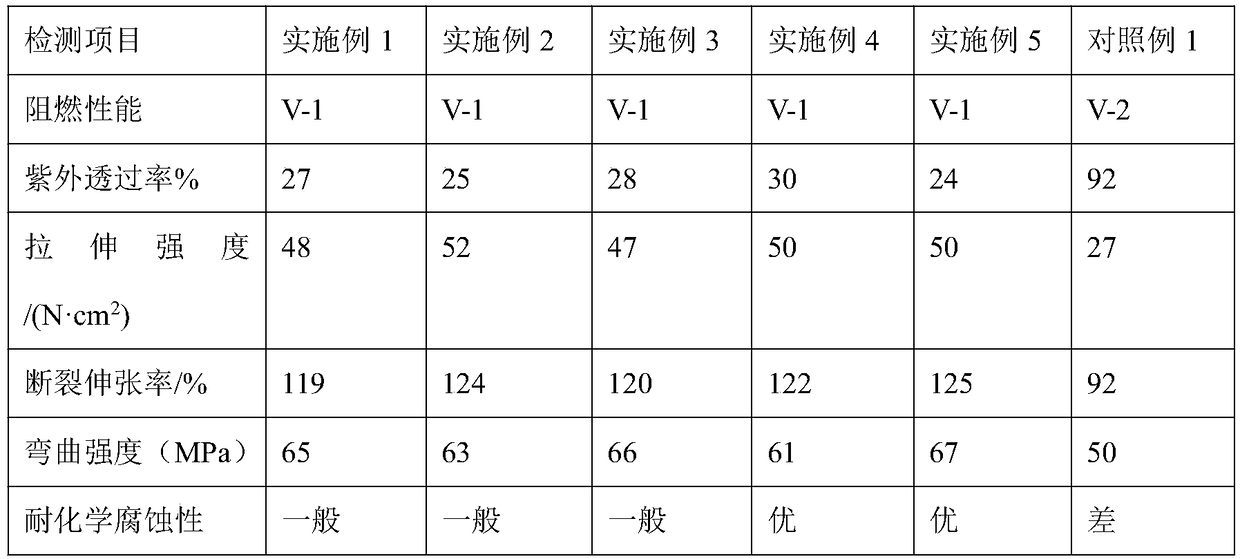

Examples

Embodiment 1

[0040] The preparation of embodiment 1 high antibacterial novel non-woven fabric

[0041] Raw material composition:

[0042] Antibacterial polypropylene 100 parts;

[0043] Nylon 640 powder;

[0044] 20 parts of titanium dioxide-cobalt phosphate;

[0045] 10 parts of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane;

[0046] 30 parts of auxiliary agent;

[0047] The mass percent of each component in the described auxiliary agent is as follows: antimony trioxide 22%, red phosphorus 8%, aluminum oxide 5%, tetrakis [β-(3,5-tertiary butyl-4-hydroxybenzene base) propionate] pentaerythritol ester 25%, resorcinol monobenzoate 27%, diethyl phthalate 13%.

[0048]Preparation of antibacterial polypropylene: Add methylchloroisothiazolinone and catalyst CuC1 into the reaction kettle, vacuumize to remove oxygen, fill with argon and add toluene as solvent, heat the system to 100°C, and stop the reaction after the powder is dissolved. Heating, cooling to 50°C, adding polymeric monomer meth...

Embodiment 2

[0051] The preparation of embodiment 2 high antibacterial novel non-woven fabrics

[0052] Raw material composition:

[0053] 120 parts of antibacterial polypropylene;

[0054] Nylon 660 powder;

[0055] 40 parts of titanium dioxide-cobalt phosphate;

[0056] 20 parts of γ-(2,3-epoxypropoxy)propyltriethoxysilane;

[0057] 50 parts of auxiliary agent;

[0058] The mass percentages of each component in the auxiliary agent are as follows: 22% antimony trioxide, 8% red phosphorus, 5% aluminum oxide, 25% tridodecyl alcohol ester, 2-(2'-hydroxyl -3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 27%, dimethyl phthalate 6%, diethyl phthalate 7%.

[0059] Preparation of antibacterial polypropylene: Add methylchloroisothiazolinone and catalyst CuC1 into the reaction kettle, vacuumize to remove oxygen, fill with argon and add toluene as solvent, heat the system to 120°C, and stop the reaction after the powder is dissolved. Heating, cooling to 60°C, adding polymerized monomer methy...

Embodiment 3

[0062] The preparation of embodiment 3 high antibacterial novel non-woven fabrics

[0063] Raw material composition:

[0064] 105 parts of antibacterial polypropylene;

[0065] Nylon 643 powder;

[0066] 22 parts of titanium dioxide-cobalt phosphate;

[0067] 12 parts of γ-mercaptopropyltriethoxysilane;

[0068] 32 parts of auxiliary agent;

[0069] The mass percent of each component in the auxiliary agent is as follows: antimony trioxide 22%, red phosphorus 8%, aluminum oxide 5%, p-phenylenediamine 25%, 2-hydroxyl-4-methoxydiphenyl ketone 27%, dioctyl phthalate 13%.

[0070] Preparation of antibacterial polypropylene: Add methylchloroisothiazolinone and catalyst CuC1 into the reaction kettle, vacuumize to remove oxygen, fill with argon and add toluene as solvent, heat the system to 110°C, and stop the reaction after the powder is dissolved. Heating, cooling to 55°C, adding polymerized monomer methyl methacrylate or tert-butyl acrylate and crosslinking agent dicumyl pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com