Fireproof door core material and preparation method thereof

A fire door and core material technology, applied in the field of flame retardant materials, can solve the problems of high energy consumption, environmental pollution, high price, complex process, etc., and achieve the effects of good flame retardant effect, easy large-scale production and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

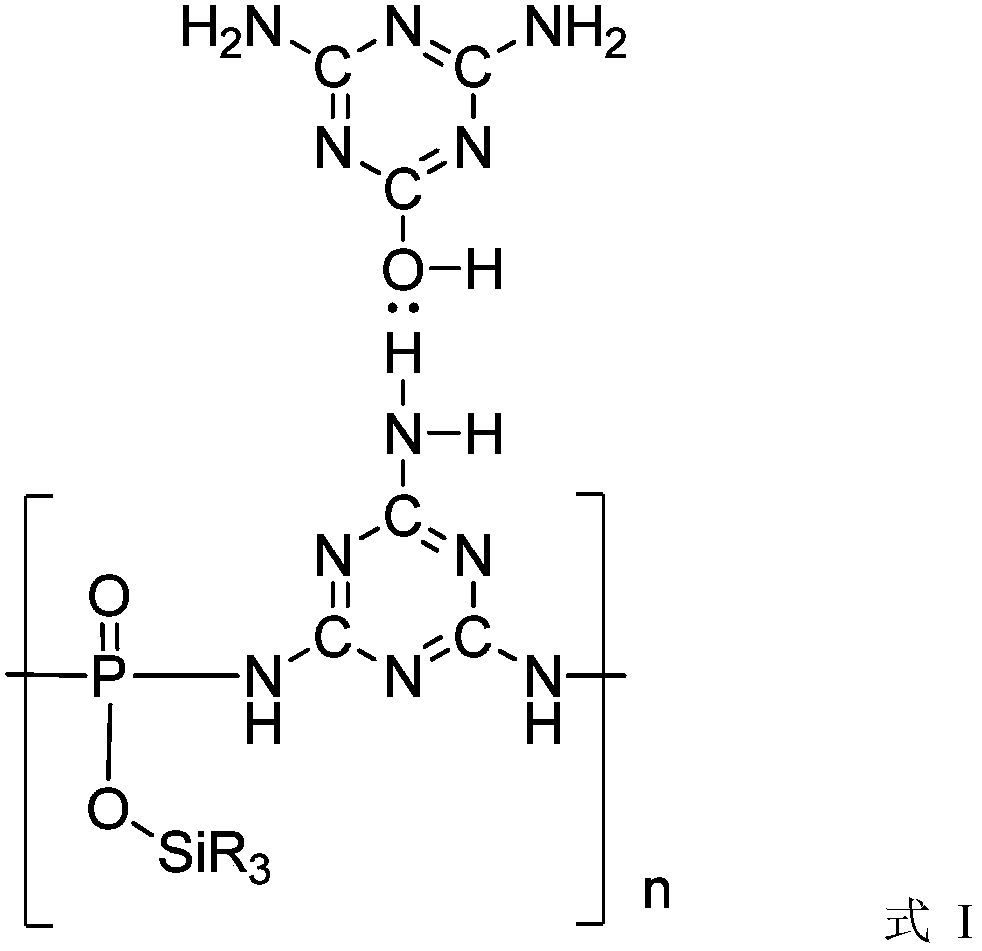

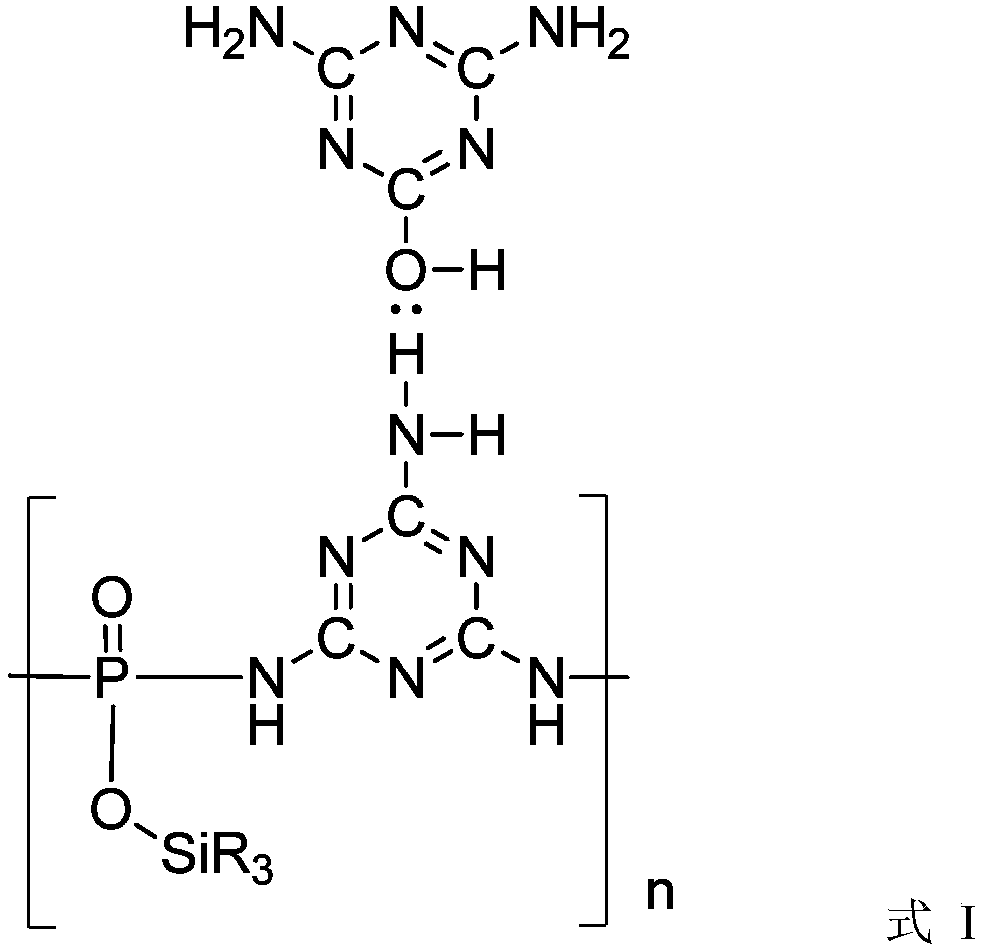

Image

Examples

Embodiment 1

[0024] A method for preparing an intumescent flame retardant material containing silicon, nitrogen and phosphorus, comprising the steps of:

[0025] (1) Under the protection of an inert gas and at room temperature, the solvent for the reaction is dichloromethane, and chlorosilane and dimethyl phosphonate are reacted for 3 hours to obtain dimethyl silyl phosphonate; the chlorosilane is Trimethylchlorosilane; the molar ratio of said chlorosilane to dimethyl phosphonate is 1: 3.5;

[0026] (2) Under the protection of an inert gas and at 370°C, react the product obtained in step (1) with dimethyl alkylsilylphosphonate and melamine for 4 hours under the action of anhydrous magnesium chloride, and cool to 300°C; the obtained product in step (1) The mol ratio of alkyl silyl phosphonate dimethyl and melamine is 1: 1.1;

[0027] Sampling, washing, drying and pulverization, the degree of polymerization of the product is 750, and the decomposition temperature of 1% thermal weight loss i...

Embodiment 2

[0031] A method for preparing an intumescent flame retardant material containing silicon, nitrogen and phosphorus, comprising the steps of:

[0032] (1) Under the protection of an inert gas and at room temperature, the solvent for the reaction is dichloromethane, and chlorosilane and dimethyl phosphonate are reacted for 3 hours to obtain dimethyl silyl phosphonate; the chlorosilane is Triethylchlorosilane; the molar ratio of said chlorosilane to dimethyl phosphonate is 1: 3;

[0033] (2) Under the protection of an inert gas and at 350°C, react the product obtained in step (1) with dimethyl alkylsilylphosphonate and melamine for 4 hours under the action of anhydrous magnesium chloride, and cool to 300°C; the obtained product in step (1) The molar ratio of dimethyl silicon-based phosphonate to melamine is 1:1.1.

[0034] Sampling, washing, drying and crushing, the degree of polymerization of the product is 990, and the decomposition temperature of 1% thermal weight loss is 235....

Embodiment 3

[0038] A method for preparing an intumescent flame retardant material containing silicon, nitrogen and phosphorus, comprising the steps of:

[0039] (1) Under the protection of an inert gas and at room temperature, the solvent for the reaction is chloroform, and chlorosilane and dimethyl phosphonate are reacted for 2 hours to obtain dimethyl silyl phosphonate; the chlorosilane is tripropyl Chlorosilane; the molar ratio of silane and dimethyl phosphonate is 1:4;

[0040] (2) Under the protection of an inert gas and at 350°C, react the dimethyl alkylsilylphosphonate obtained in step (1) with melamine under the action of triphenyl phosphate for 3 hours, and cool to 300°C; step (1) The molar ratio of the resulting alkylsilylphosphonic acid dimethyl to melamine is 1:1.1.

[0041] Sampling, washing, drying and crushing, the product has a degree of polymerization of 800 and a decomposition temperature of 1% thermal weight loss of 237.6°C.

[0042] (3) Cool down to 250°C at a rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermogravimetric decomposition temperature | aaaaa | aaaaa |

| Thermogravimetric decomposition temperature | aaaaa | aaaaa |

| Thermogravimetric decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com