Modified processing method of natural rubber

A technology of natural rubber and treatment method, applied in the field of modification treatment of natural rubber, can solve the problems of slow modification reaction rate, easy occurrence of side reactions, poor compatibility of natural rubber, etc. Good thermal stability and chemical inertness, and the effect of enhancing the interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

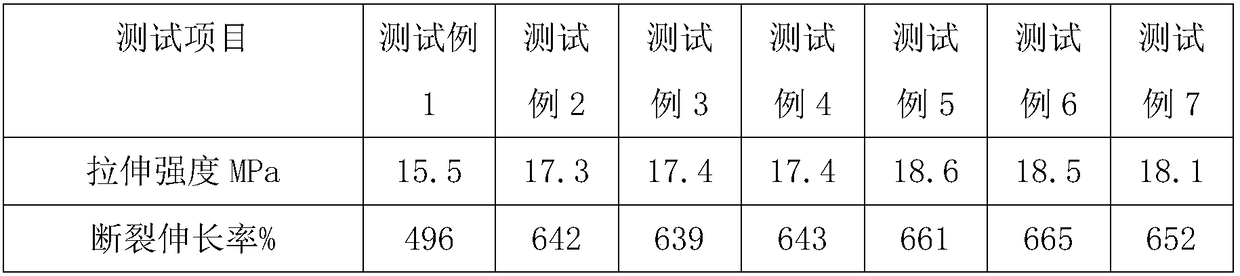

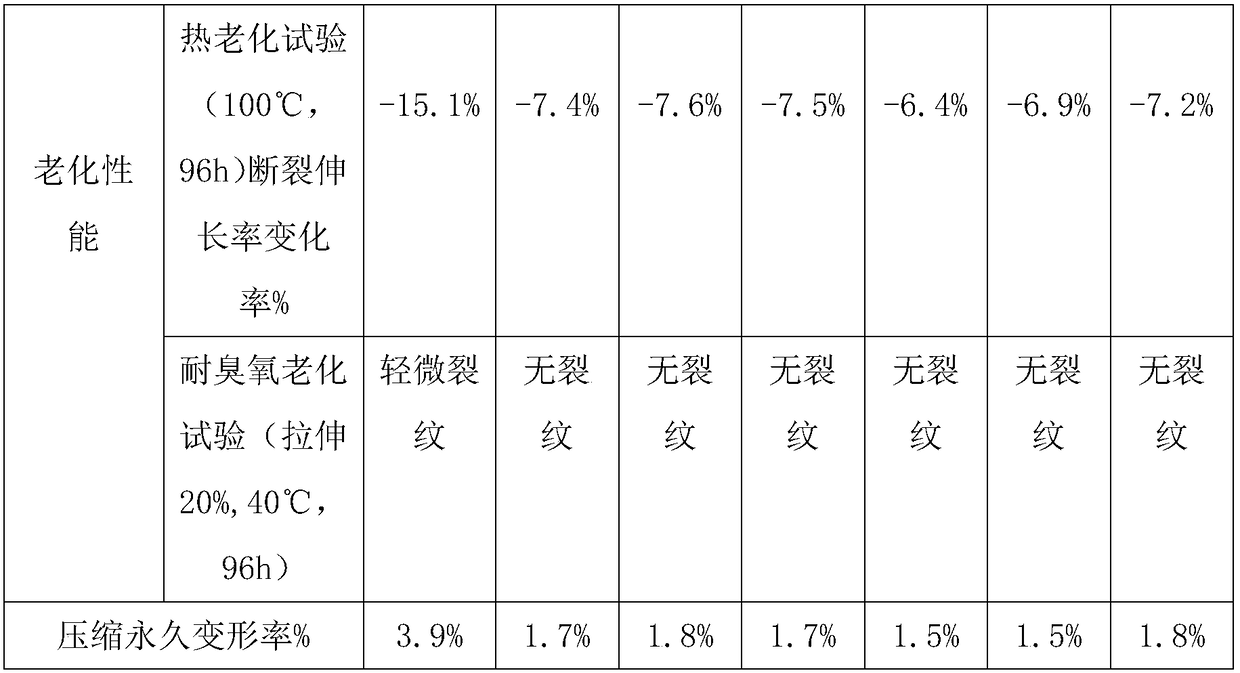

Examples

Embodiment 1

[0036] A modification treatment method of natural rubber, comprising the steps of:

[0037] (1) According to the mass parts, 200 parts of purified latex, 7.2 parts of 10wt% polyoxyethylene lauryl ether sodium sulfate aqueous solution, 15 parts of 30wt% sodium hydroxide solution and 100 parts of deionized water are added to the reactor , continuously stirred at a speed of 120r / min, and saponified at a temperature of 30°C for 18h;

[0038] (2) In the product in the reaction kettle of the upward step, add 20wt% hydrochloric acid solution for neutralization, then add acrylic acid and glutamic acid and other mixed acids in molar ratio to adjust the pH of the mixture to 5;

[0039] (3) Add 5 parts of 2-mercaptoethanol, 6 parts of vinyl acetate and 9 parts of vinylcyclopropane into the reactor, adjust the temperature of the reactor to 65°C, and stir at a speed of 200r / min for 10min; Add 8 parts of catalytic suspending agent into the kettle, and continue to stir at the same speed for...

Embodiment 2

[0047] A modification treatment method of natural rubber, comprising the steps of:

[0048] (1) According to the number of parts by mass, 200 parts of purified latex, 7.2 parts of 10wt% polyoxyethylene lauryl ether sodium sulfate aqueous solution, 15 parts of 30wt% sodium hydroxide solution and 100 parts of deionized water are added to the reactor , continuously stirred at a speed of 150r / min, and saponified at a temperature of 35°C for 24h;

[0049] (2) In the product in the upward step reactor, add 20wt% hydrochloric acid solution for neutralization, then add methacrylic acid and glutamic acid and other mixed acids in molar ratio to adjust the pH of the mixture to 5.2;

[0050] (3) Add 5 parts of 2-mercaptoethanol, 6 parts of vinyl acetate and 9 parts of vinylcyclopropane into the reactor, adjust the temperature of the reactor to 80°C, and stir at a speed of 250r / min for 13min; Add 8 parts of catalytic suspending agent into the kettle, and continue to stir at the same speed...

Embodiment 3

[0058] A modification treatment method of natural rubber, comprising the steps of:

[0059] (1) According to the number of parts by mass, 200 parts of purified latex, 7.2 parts of 10wt% polyoxyethylene lauryl ether sodium sulfate aqueous solution, 15 parts of 30wt% sodium hydroxide solution and 100 parts of deionized water are added to the reactor , continuously stirred at a speed of 140r / min, and saponified at a temperature of 33°C for 22h;

[0060] (2) In the product in the reaction kettle of the upward step, add 20wt% hydrochloric acid solution for neutralization, then add styrene acid and glutamic acid and other mixed acids in molar ratio to adjust the pH of the mixture to 5.1;

[0061] (3) Add 5 parts of 2-mercaptoethanol, 6 parts of vinyl acetate and 9 parts of vinylcyclopropane into the reactor, adjust the temperature of the reactor to 70°C, and stir for 12min at a speed of 230r / min; Add 8 parts of catalytic suspending agent into the kettle, and continue to stir at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com