Photo-thermal catalytic hydrogenation catalyst as well as preparation method and application thereof

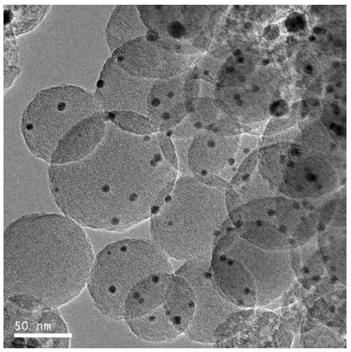

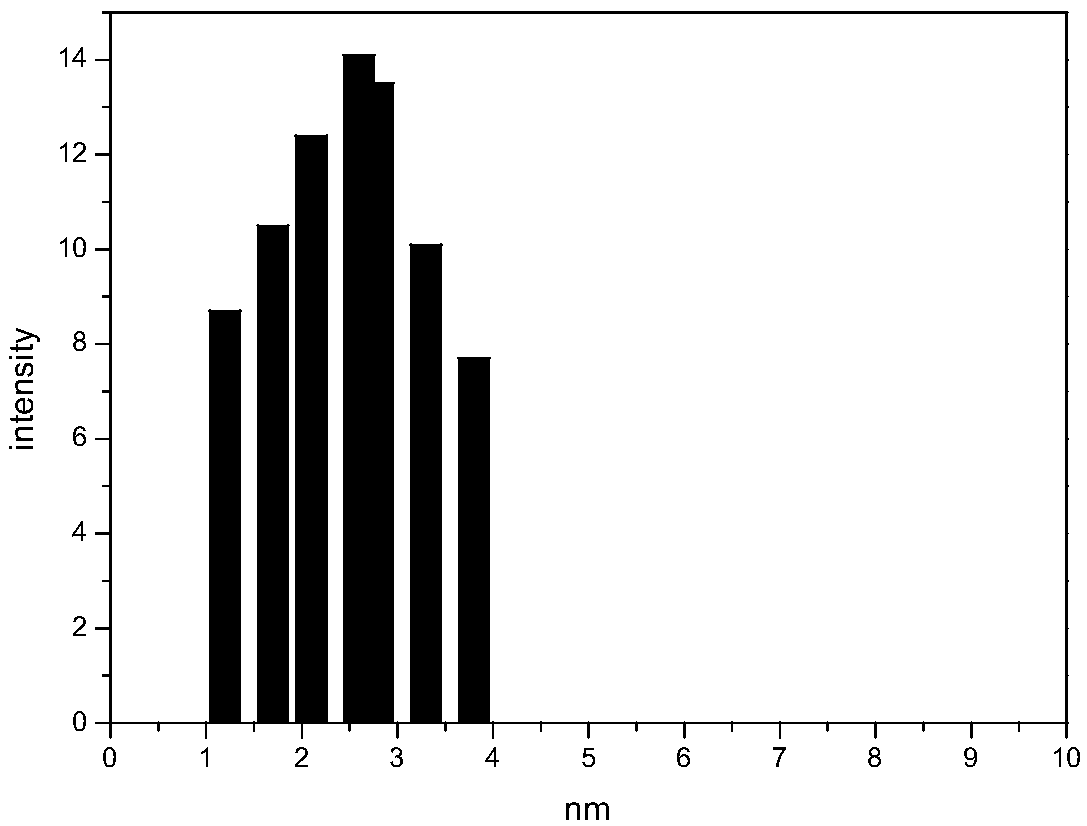

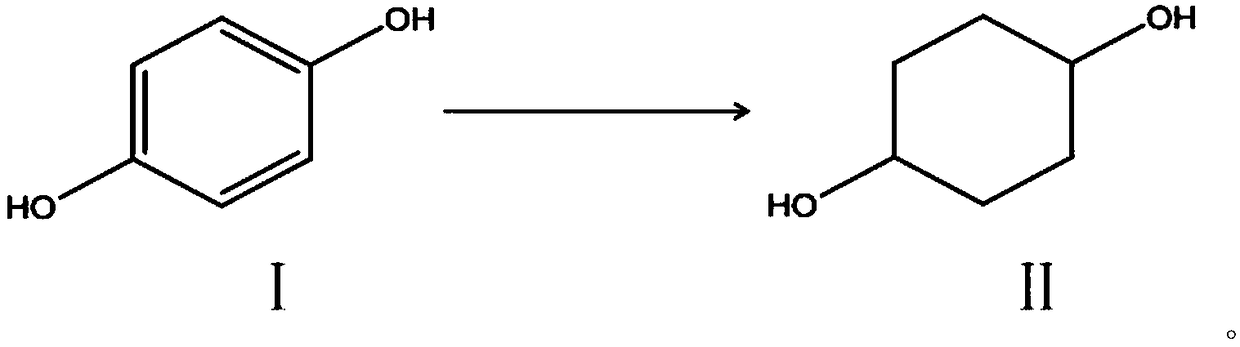

A hydrogenation catalyst, photothermal catalysis technology, applied in physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, hydrogenation preparation, etc., can solve the problem of low yield of 1,4-cyclohexanediol , the complex process of bimetallic catalysts, the high price of iodine shirts, etc., to achieve the effect of low catalyst dosage, accurate and controllable particle size distribution range, and improved metal utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Measure 1ml of ammonia water with a mass concentration of 23%, 32ml of ethanol and 80ml of deionized water and mix them thoroughly, then add 3.5g of 3-aminophenol, stir until completely dissolved, then drop in 5ml of formaldehyde solution with a mass concentration of 35%, and leave at room temperature After stirring at low temperature for 4 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours. After cooling to room temperature, it was placed in an oven and dried at 60°C for 24 hours to obtain polymer microspheres.

[0034] Weigh 1g of polymer microspheres and 15ml of deionized water and stir until fully dispersed, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 165°C, and microwave reaction time for 15 minutes for microwave reaction. Take out the mixed slurry, put it into a vacuum oven, and dry at 60° C. for 24 hours under a relative vacuum degree of -0.099 to -0.05 MPa...

Embodiment 2

[0039] Measure 1ml of ammonia water with a mass concentration of 20%, 20ml of ethanol and 70ml of deionized water and mix them thoroughly, then add 2g of 3-aminophenol, stir until completely dissolved, and then drop in 2m of formaldehyde solution with a mass concentration of 33%l. After stirring at low temperature for 2 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 100°C for 12 hours. After cooling to room temperature, it was put into an oven and dried at 20°C for 12 hours.

[0040] Weigh 1g of polymer microspheres and 15ml of deionized water and stir until fully dispersed, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 165°C, and microwave reaction time for 15 minutes for microwave reaction. Take out the mixed slurry, put it into a vacuum oven, and dry at 60° C. for 24 hours under a relative vacuum degree of -0.099 to -0.05 MPa to obtain a solid powder.

[0041] After mixing 1g of the ...

Embodiment 3

[0045] Measure 1ml of ammonia water with a mass concentration of 25%, 60ml of ethanol and 100ml of deionized water and mix them thoroughly, then add 5g of 3-aminophenol, stir until completely dissolved, and then drop in 8ml of formaldehyde solution with a mass concentration of 38%. After stirring for 10 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 300° C. for 48 hours. After cooling to room temperature, it was put into an oven and dried at 80° C. for 48 hours.

[0046] Weigh 1g of polymer microspheres and 15ml of deionized water and stir until fully dispersed, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 165°C, and microwave reaction time for 15 minutes for microwave reaction. Take out the mixed slurry, put it into a vacuum oven, and dry at 60° C. for 24 hours under a relative vacuum degree of -0.099 to -0.05 MPa to obtain a solid powder.

[0047] After mixing 1g of the carbon micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com