Recycling method of arsenic-containing gypsum slag

A gypsum slag, recycling technology, applied in the improvement of process efficiency, calcium/strontium/barium halide, calcium/strontium/barium fluoride, etc., can solve soil and water pollution, large amount of arsenic-containing waste, and treatment costs. Advanced problems, to achieve the effect of reducing process costs, reducing costs, and achieving recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

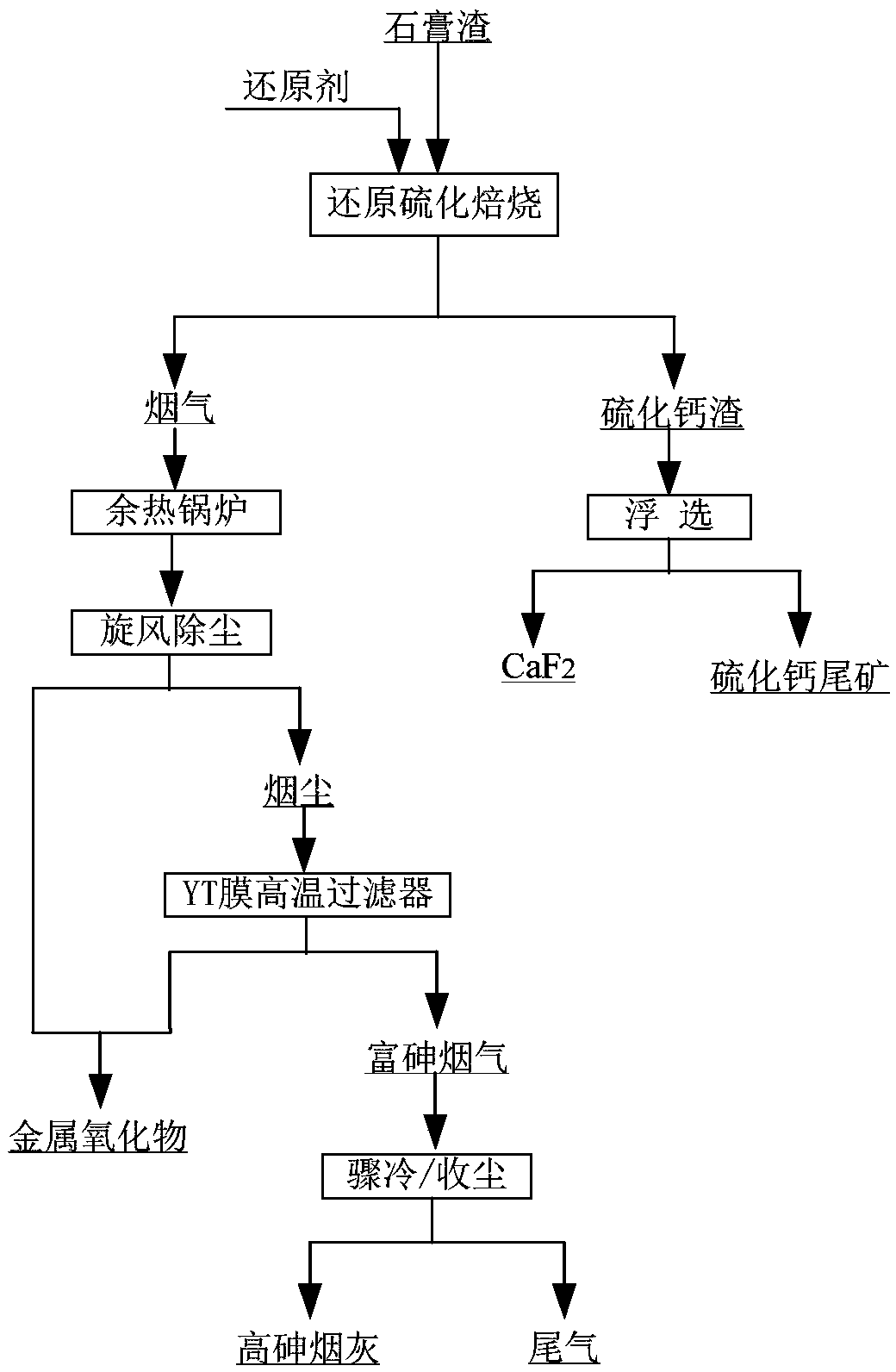

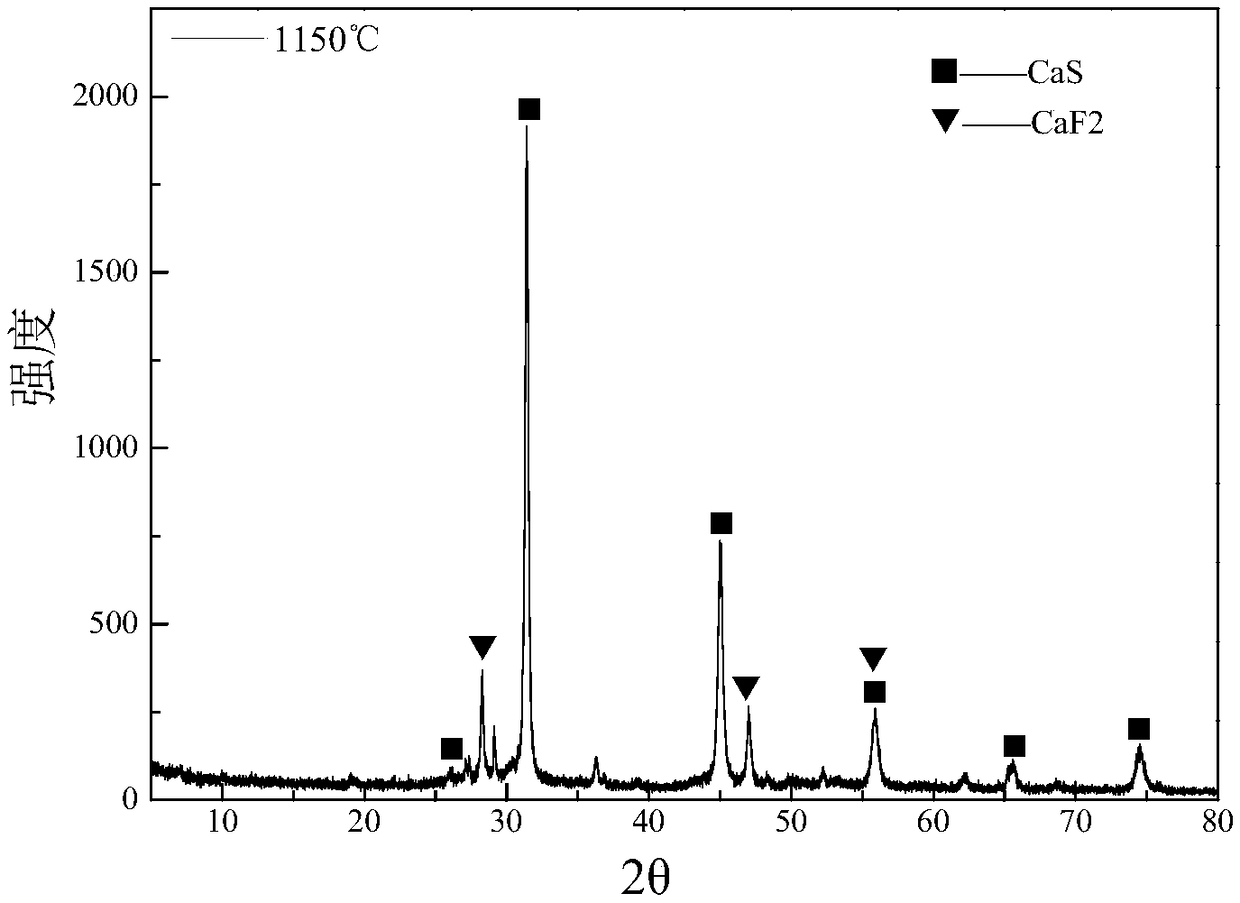

[0030] The gypsum slag produced by the conventional lime neutralization method of a lead and zinc smelting enterprise in Hunan is used as raw material, and its main components are shown in Table 1; take 1000 kg of the dried gypsum slag, and add powder with a mass of 20% of the gypsum slag mass. Mix the coal evenly, place it in a closed rotary kiln, and bake it at 1150°C for 60 minutes.

[0031] The flue gas volatilized during the roasting process is oxidized by blowing air to oxidize the metal element in the flue gas into oxides, and then cooled by the waste heat boiler (control the cooling temperature to ensure that the temperature of the flue gas entering the YT (intermetallic compound) membrane high-temperature filter is 360 ~400°C), cyclone dust collector, and YT membrane high-temperature filter to obtain heavy metal oxide dust, and the filtered flue gas is quenched to below 180°C to obtain high-arsenic soot.

[0032] After cooling the roasted product obtained, calcium sul...

Embodiment 2

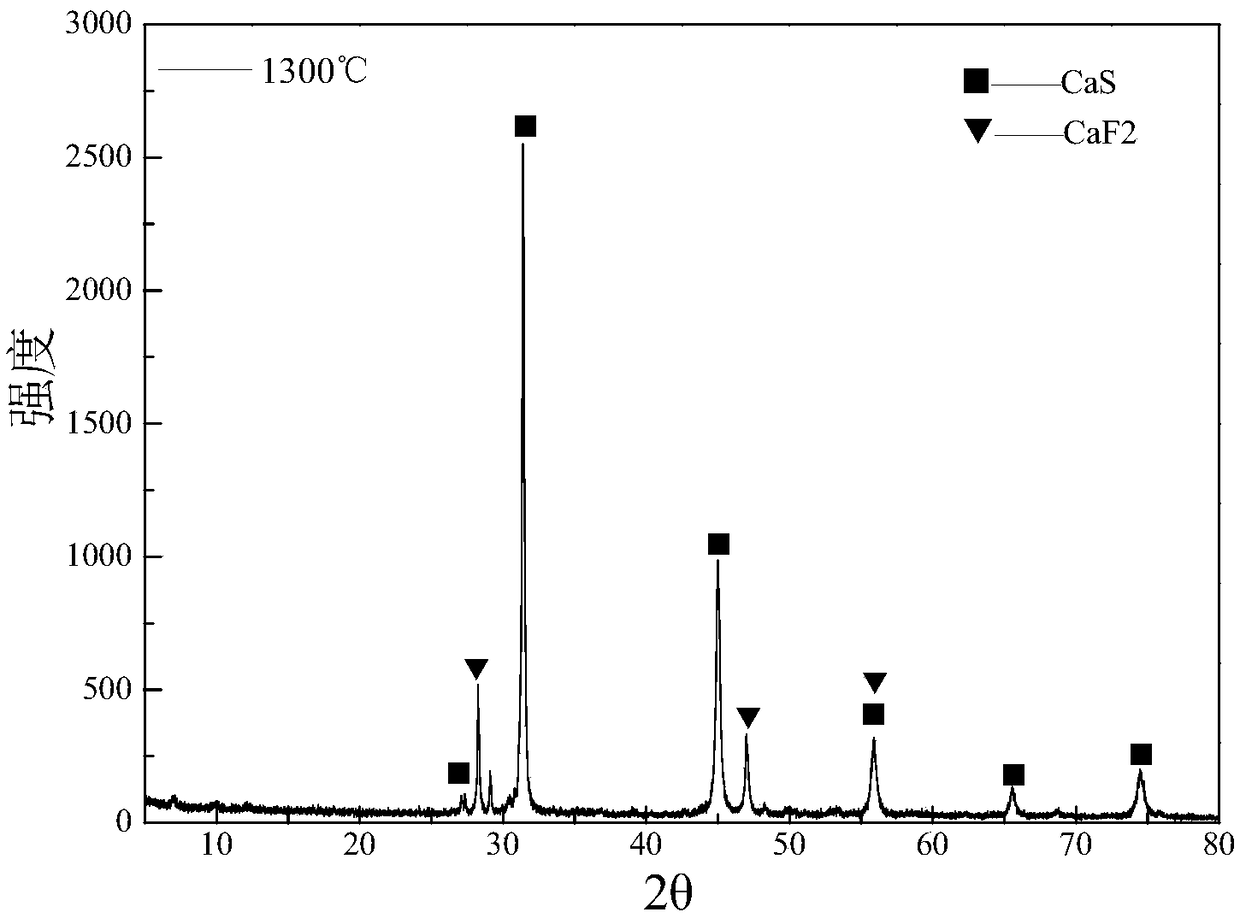

[0038] The gypsum slag produced by the conventional lime neutralization method of a copper smelting enterprise in Yunnan is used as raw material, and its main components are shown in Table 2; 1000 kg of the dried gypsum slag is taken, and a powdered coal mixture with a mass of 25% of the gypsum slag mass is added. Evenly, put it in a closed rotary kiln, and bake it at 1300°C for 30min.

[0039] The flue gas volatilized during the roasting process is oxidized by blasting to oxidize the metal element in the flue gas into oxides, and then cooled by the waste heat boiler (control the cooling temperature to ensure that the temperature of the flue gas entering the YT membrane high-temperature filter is 360-400 ° C), Dust is collected by a cyclone dust collector and filtered by a YT membrane high-temperature filter to obtain metal oxide dust, and the filtered flue gas is quenched to below 180°C to obtain high-arsenic soot.

[0040] After cooling the roasted product obtained, calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com