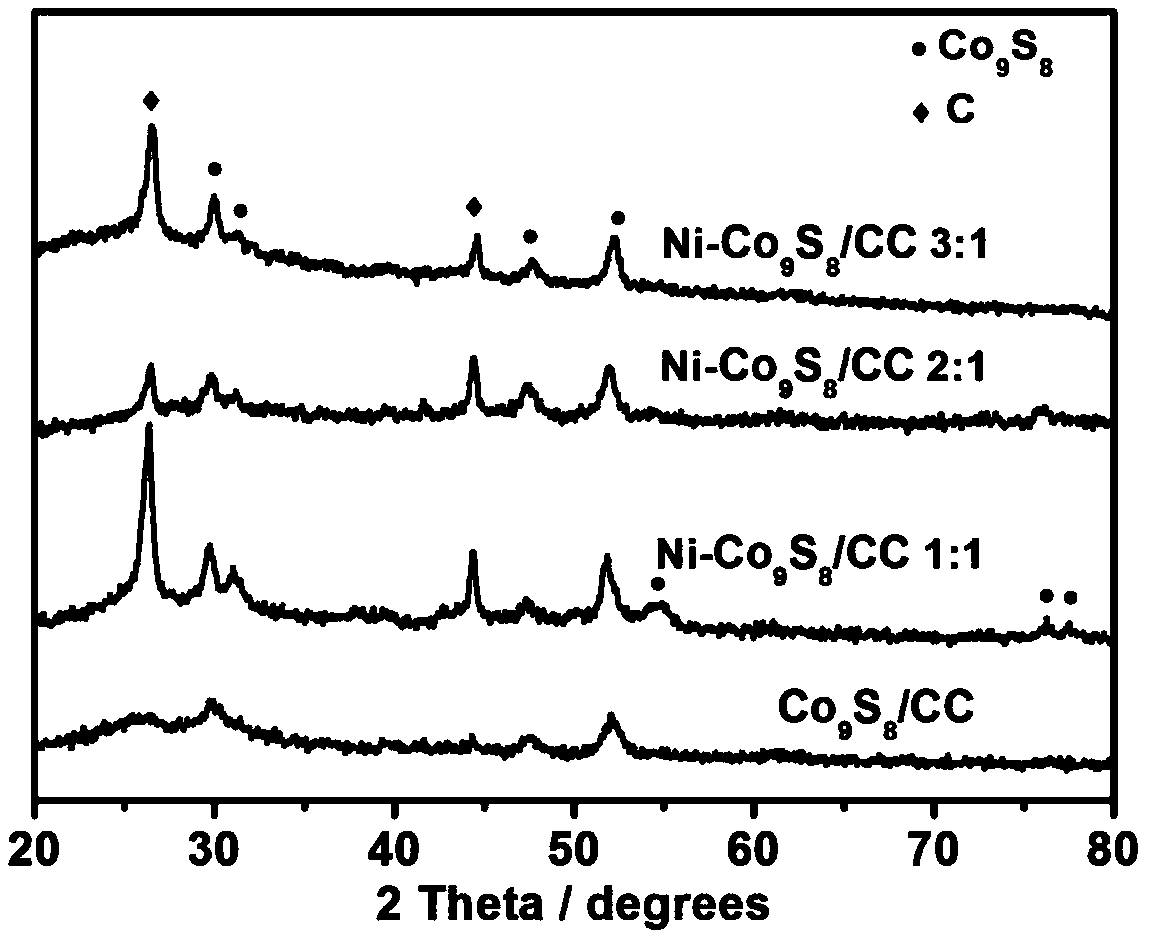

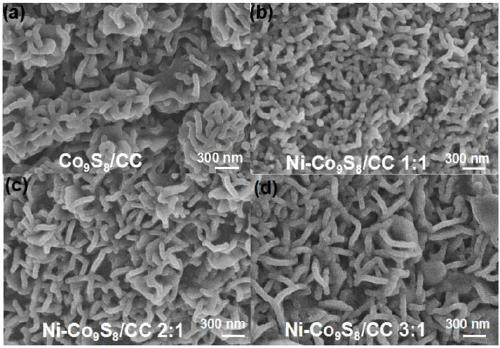

Nickel-doped Co<9>S<8> nano-sheet dual-function electro-catalyst and method for preparing same

A technology of electrocatalysts and nanosheets, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., to achieve the effects of reducing overvoltage, improving electrocatalytic performance, and simple process preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A nickel-doped Co 9 S 8 A method for preparing a nanosheet bifunctional electrocatalyst, comprising the steps of:

[0055] (1) Soak the carbon cloth in concentrated nitric acid for 30 minutes, then ultrasonically wash it with deionized water and ethanol for 20 minutes; then dry it in a drying oven for 10 hours, and set aside;

[0056] (2) Dissolve 3mM cobalt chloride hexahydrate and 3mM nickel chloride hexahydrate in 100 ml of deionized water, stir the solution containing gu ions and nickel ions for 2h, then immerse the carbon cloth in step (1) in the above solution , using carbon cloth as the working electrode, platinum mesh as the counter electrode, and calomel electrode as the reference electrode, deposited at a constant voltage of -1.0V for 5 min; rinsed the deposited carbon cloth with deionized water, and dried it at 50°C 12h, obtain the Ni-Co nano sheet precursor that is deposited on the carbon cloth, standby;

[0057] (3) Dissolve 8 mmol of thioacetamide in 40...

Embodiment 2

[0059] A nickel-doped Co 9 S 8 A method for preparing a nanosheet bifunctional electrocatalyst, comprising the steps of:

[0060] (1) Soak the carbon cloth in concentrated nitric acid for 30 minutes, then ultrasonically wash it with deionized water and ethanol for 20 minutes; then dry it in a drying oven for 10 hours, and set aside;

[0061] (2) Dissolve 6mM cobalt chloride hexahydrate and 3mM nickel chloride hexahydrate in 100 ml of deionized water, stir the solution containing gu ions and nickel ions for 2h, then immerse the carbon cloth in step (1) in the above solution , the carbon cloth was used as the working electrode, the platinum mesh was used as the counter electrode, and the calomel electrode was used as the reference electrode. It was deposited at a constant voltage of -1.0V for 5 min; the deposited carbon cloth was rinsed with deionized water and dried at 50°C for 12 h , to obtain Ni-Co nanosheet precursors deposited on carbon cloth,

[0062] spare;

[0063] (...

Embodiment 3

[0065] A nickel-doped Co 9 S 8 A method for preparing a nanosheet bifunctional electrocatalyst, comprising the steps of:

[0066] (1) Soak the carbon cloth in concentrated nitric acid for 30 minutes, then ultrasonically wash it with deionized water and ethanol for 20 minutes; then dry it in a drying oven for 10 hours, and set aside;

[0067] (2) Dissolve 9mM cobalt chloride hexahydrate and 3mM nickel chloride hexahydrate in 100 ml of deionized water, stir the solution containing gu ions and nickel ions for 2h, then immerse the carbon cloth in step (1) in the above solution , the carbon cloth was used as the working electrode, the platinum mesh was used as the counter electrode, and the calomel electrode was used as the reference electrode. It was deposited at a constant voltage of -1.0V for 5 min; the deposited carbon cloth was rinsed with deionized water and dried at 50°C for 12 h , to obtain the Ni-Co nanosheet precursor deposited on the carbon cloth, for subsequent use; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com