A kind of separation and utilization process of threonine waste mother liquor

A technology of waste mother liquor and threonine, which is applied in the field of threonine mother liquor treatment, can solve the problems of high cost, high cost of medium raw materials, large one-time investment, etc., and achieve load reduction, remarkable ecological and economic benefits, and rapid adaptation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of separation and utilization process of threonine waste mother liquor, it comprises the following steps:

[0033] Threonine waste mother liquor is first filtered through an inorganic ceramic membrane with a molecular weight cut-off of 10,000 Da and a filtration temperature of 32°C to collect bacterial protein, and the filtrate is discharged into an acid-base adjustment tank, and the pH of the liquid is adjusted to 6.5 by adding KOH solution;

[0034]The waste liquid discharged from the acid-base adjustment tank enters the microbial reaction tank, then adds 5wt% rice straw powder, 2wt% wheat bran and 1wt% soybean meal, stirs at 300rpm for 120min, and then inoculates Scenedesmus obliquus according to the inoculum amount of 3%. After cultivating for 12 hours, inoculate the Trichoderma reesei liquid according to the inoculation amount of 6%, after continuing to cultivate for 12 hours, inoculate the Aspergillus niger liquid according to the inoculum amount of 8%, cont...

Embodiment 2

[0044] A kind of separation and utilization process of threonine waste mother liquor, it comprises the following steps:

[0045] Threonine waste mother liquor is first filtered through an inorganic ceramic membrane with a molecular weight cut-off of 10,000 Da and a filtration temperature of 32°C to collect bacterial protein, and the filtrate is discharged into an acid-base adjustment tank, and the pH of the liquid is adjusted to 6.5 by adding KOH solution;

[0046] The waste liquid discharged from the acid-base adjustment tank enters the microbial reaction tank, then adds 5wt% rice straw powder, 2wt% wheat bran and 1wt% soybean meal, stirs at 300rpm for 120min, and then inoculates Scenedesmus obliquus according to the inoculation amount of 5%. After cultivating for 18 hours, inoculate the Trichoderma reesei liquid according to the inoculum of 8%, after continuing to cultivate for 12 hours, inoculate the Aspergillus niger liquid according to the inoculum of 10%, continue to cult...

Embodiment 3

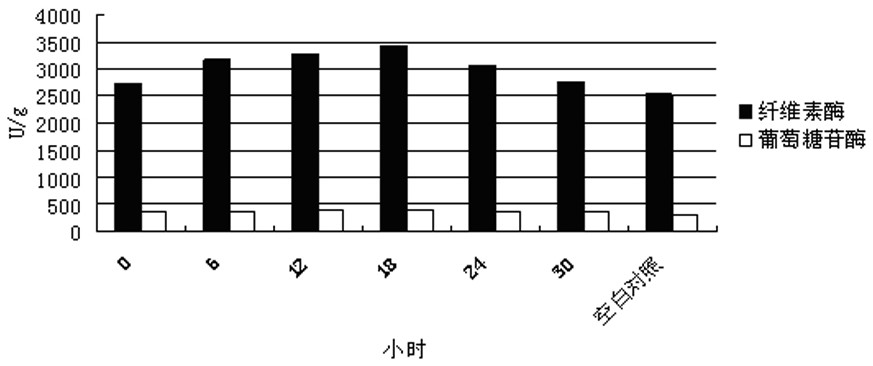

[0056] Synergistic effect test between each microorganism of the present invention:

[0057] 1, test group is embodiment 1; Control group 1 adopts Trichoderma reesei single bacterial strain, all the other are with embodiment 1; Control group 2 adopts Aspergillus niger single bacterial strain, all the other are with embodiment 1; Detected cellulase in culture respectively , glucosidase, acid protease enzyme activity, the specific results are shown in Table 1:

[0058] Table 1

[0059] group Cellulase U / g Glucosidase U / g Alkaline protease U / g test group 3207 413 7516 Control group 1 2639 308 ----- Control group 2 ----- ----- 5745

[0060] Conclusion: Trichoderma reesei and Aspergillus niger selected in the present invention have a better synergistic effect, which greatly improves the enzyme activity of cellulase, glucosidase and acid protease, and contributes to the improvement of sugars and waste proteins in waste liquid. and degrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com