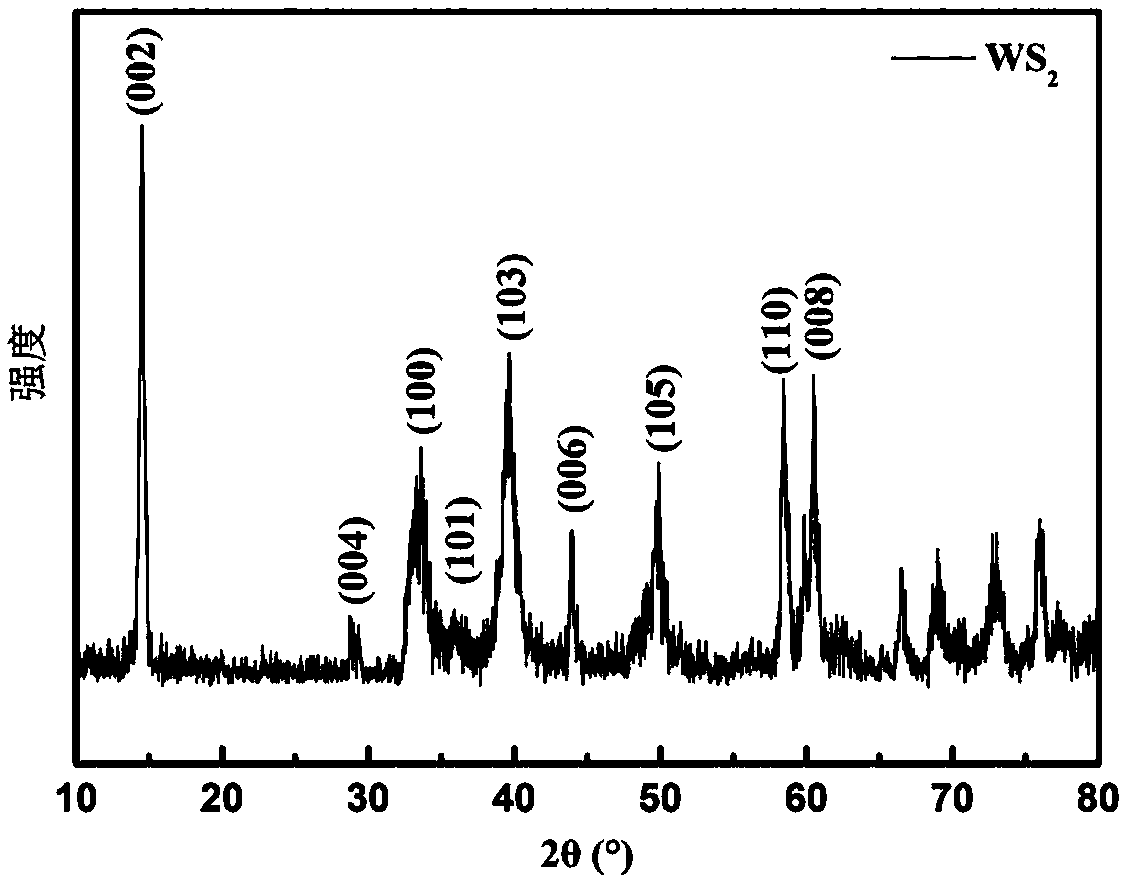

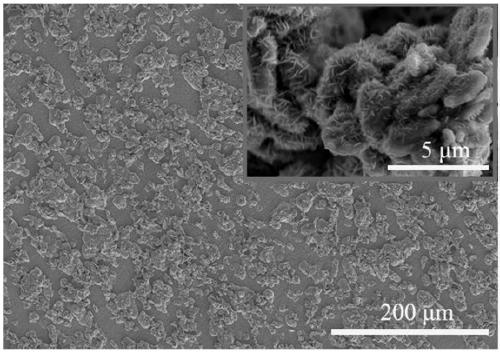

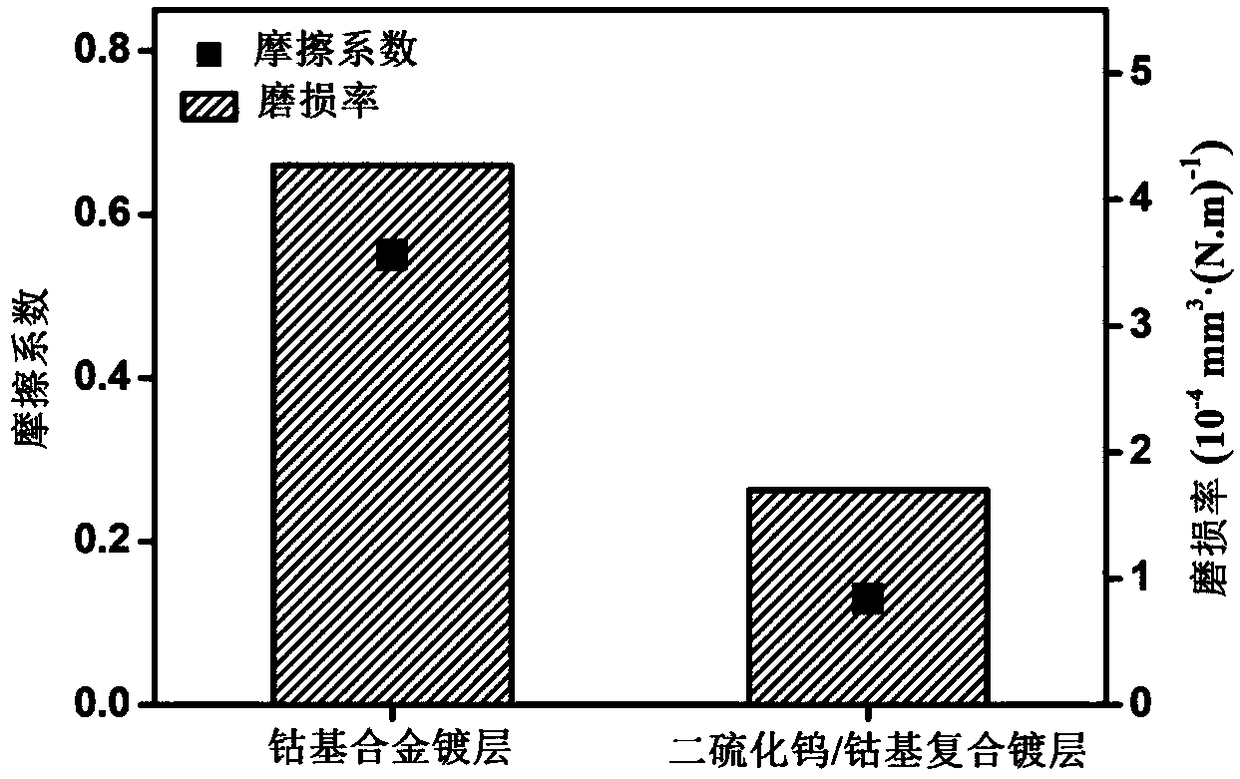

Tungsten disulfide/cobalt disulfide based composite coating and preparation method and application thereof

A tungsten disulfide and composite coating technology, applied in coatings, electrodes, electrolytic coatings, etc., to reduce friction coefficient and wear rate, excellent wear and corrosion resistance, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Configure composite electroplating solution: dissolve cobalt sulfate, nickel sulfate, boric acid, sodium gluconate, n-octyltrimethylammonium bromide, and tungsten disulfide into deionized water to make a composite electroplating solution; among them, cobalt sulfate The concentration is 30g / L, the concentration of nickel sulfate is 30g / L, the concentration of boric acid is 20g / L, the concentration of sodium gluconate is 20g / L, and the concentration of n-octyltrimethylammonium bromide is 0.1g / L, The concentration of tungsten disulfide is 6g / L, and the pH value of the electroplating solution is adjusted to 2.5 with sodium hydroxide and dilute sulfuric acid.

[0034] 2. Take the anode as a cobalt sheet, and the cathode as a No. 45 steel substrate through degreasing-cleaning-acid activation, and the distance between the two electrodes is 3cm. The above-mentioned anode and cathode are immersed in the electroplating solution obtained in step S1, and the power is 50W. After ...

Embodiment 2

[0036] 1. Configure composite electroplating solution: dissolve cobalt sulfate, nickel sulfate, boric acid, sodium citrate, cetyltrimethylammonium bromide, and tungsten disulfide into deionized water to make a composite electroplating solution; among them, cobalt sulfate The concentration of nickel sulfate is 50g / L, the concentration of nickel sulfate is 50g / L, the concentration of boric acid is 40g / L, the concentration of sodium citrate is 40g / L, and the concentration of cetyltrimethylammonium bromide is 0.1g / L L, the concentration of tungsten disulfide is 8g / L, and the pH value of electroplating solution is adjusted to 3 with sodium hydroxide and dilute sulfuric acid.

[0037] 2. The anode is a nickel sheet, and the cathode is a brass substrate that has undergone degreasing-cleaning-acid activation. The distance between the two electrodes is 2cm. The above-mentioned anode and cathode are immersed in the electroplating solution obtained in step S1, and the power is 80W. Ultras...

Embodiment 3

[0040] 1. Configure a composite electroplating solution: dissolve cobalt sulfate, nickel chloride, boric acid, ammonium citrate, sodium lauryl sulfate, and tungsten disulfide into deionized water to make a composite electroplating solution; wherein the concentration of cobalt sulfate is 100g / L, the concentration of nickel chloride is 100g / L, the concentration of boric acid is 30g / L, the concentration of ammonium citrate is 30g / L, the concentration of sodium lauryl sulfate is 0.2g / L, the concentration of tungsten disulfide The concentration is 10g / L, and the pH value of the electroplating solution is adjusted to 4 with sodium hydroxide and dilute sulfuric acid.

[0041] 2. The anode is a nickel sheet, and the cathode is a No. 45 steel substrate that has undergone degreasing-cleaning-acid activation. The distance between the two electrodes is 4cm. The above-mentioned anode and cathode are immersed in the electroplating solution obtained in step S1. After ultrasonic vibration in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com