Method for preparing integrated molecular sieve blocks on basis of 3D printing technology

A 3D printing, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, ceramic products, etc., can solve the problems of large pressure drop of catalysts, low mass or heat transfer efficiency, easy wear, etc. High mass and heat transfer efficiency, the effect of increasing the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

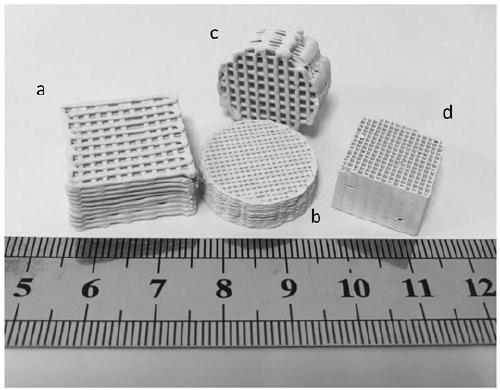

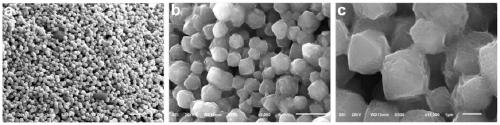

Embodiment 1

[0034] (1) Mix the commercialized 4A molecular sieve powder (belonging to LTA topological structure) with kaolin and ceramic fiber, grind it manually with agate for half an hour, and then mechanically stir it for 1 hour to obtain the mixed powder; the organic plasticizer carboxymethyl Add base cellulose and pore-forming agent flour to water equivalent to 45% of the mass of 4A molecular sieve powder, mix to a uniform jelly, then add to the above mixed powder, and use mechanical stirring to mix again to obtain a uniform paste mixture; paste In the mixture, the mass fraction of 4A molecular sieve powder is 80%, the mass fraction of kaolin is 10%, the mass fraction of ceramic fiber is 3%, the mass fraction of organic plasticizer is 4%, and the mass fraction of pore-forming agent is 3%;

[0035] (2) Ultrasonic treatment is carried out to the paste mixture obtained, the ultrasonic power is 40 kHz, and the ultrasonic time is 10 minutes, to eliminate the air bubbles wrapped in the pas...

Embodiment 2

[0039] (1) Manually grind the commercial NaX molecular sieve powder (belonging to the FAU topology) with attapulgite and glass fiber with agate for 1 hour, and then mechanically stir for 1 hour to obtain a mixed powder; at the same time, the organic plasticizer Add polyvinyl alcohol and pore-forming agent cornstarch to water with 50% of the mass of NaX molecular sieve powder, mix to a uniform jelly, then add to the above-mentioned mixed powder, and use mechanical stirring to mix again to obtain a uniform paste mixture; , the mass fraction of NaX molecular sieve powder is 75%, the mass fraction of attapulgite is 13%, the mass fraction of glass fiber is 2%, the mass fraction of polyvinyl alcohol is 5%, and the mass fraction of corn starch is 5%;

[0040] (2) Ultrasonic treatment is carried out to the paste mixture obtained, the power is 30 kilohertz, and the time is 20 minutes, to eliminate the air bubbles wrapped in the paste;

[0041] (3) Use Auto CAD software to construct the...

Embodiment 3

[0045] (1) The commercial ZSM-5 molecular sieve powder (belonging to MFI topological structure) and sepiolite and quartz fiber were manually ground for 20 minutes with an agate mortar, and then mechanically stirred for 2 hours to obtain a mixed powder; at the same time, The organic plasticizer polyacrylamide and the pore-forming agent kale powder are added to water with a mass of 30% of the MFI molecular sieve powder, mixed to a uniform jelly, then added to the above-mentioned mixed powder, and mixed again by mechanical stirring to obtain a uniform paste Mixture;; In the pasty mixture, the mass fraction of ZSM-5 molecular sieve powder is 70%, the mass fraction of sepiolite is 18%, the mass fraction of quartz fiber is 4%, and the mass fraction of polyacrylamide is 4%, The mass fraction of tianjing powder is 4%;

[0046] (2) Ultrasonic treatment is carried out to the paste mixture obtained, the power is 20 kilohertz, and the time is 30 minutes, to eliminate the air bubbles wrapp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com