Preparation method of crystal nucleus type concrete super-early strength agent

A technology of concrete and early strength agent, applied in the application field of concrete admixtures, can solve the problems of reducing the compressive strength of concrete, increasing the amount of admixtures, deteriorating the workability of concrete, etc. Toughness, effect of improving super early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

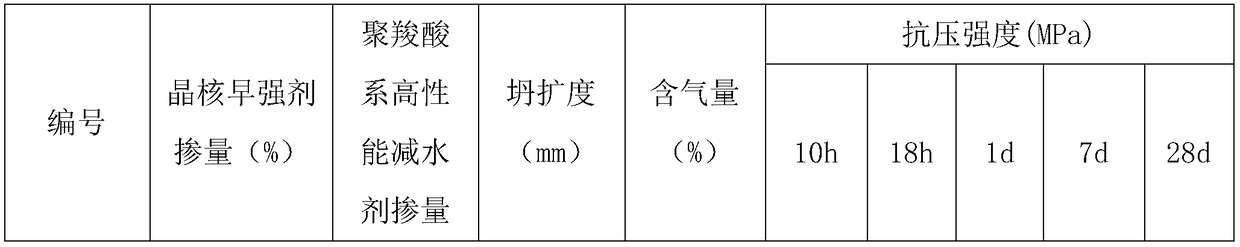

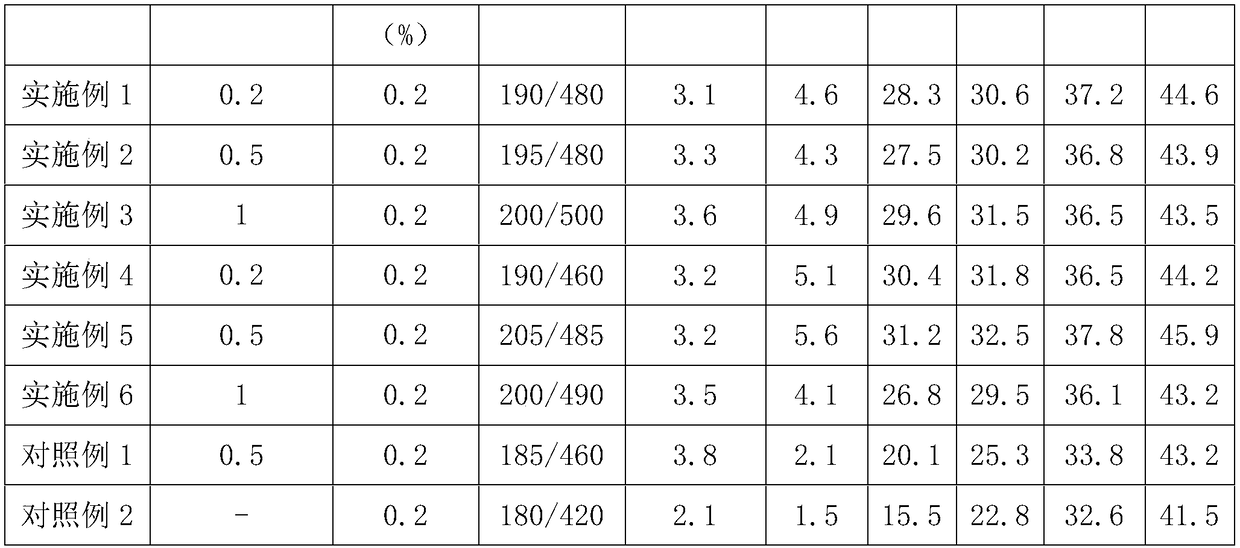

Examples

example 1

[0024](1) Preparation of modified magnesium silicate solution: under nitrogen protection, dissolve 0.49g (C5H5)2Fe / tris[2-(dimethylamino)ethyl]amine in 12g of ethylene glycol, add 10g of hydrated silicon Magnesium silicate and 150 g of deionized water were stirred for 4 hours to obtain a modified magnesium silicate solution.

[0025] (2) Preparation of modified calcium-silicon aqueous solution: 1g nano-titanium dioxide (15nm) is suspended in 130g water, at 50 DEG C, begin to drop the calcium acetate aqueous solution 100g of mass concentration 10.2% and the silica sol (pH is 2.1) 80g was added dropwise for 10 hours to obtain a modified calcium-silicon aqueous solution.

[0026] (3) Preparation of telechelic polymer: After adding 0.02mol ammeline and 0.003mol sodium hydroxide to the reaction kettle, vacuumize, replace with nitrogen, heat to 130°C, and then continuously add 1mol ring Ethylene oxide and 0.2mol propylene oxide were subjected to a ring-opening reaction for 6 hours ...

example 2

[0029] (1) Preparation of modified magnesium silicate solution: under nitrogen protection, 0.1g (C 5 h 5 ) 2 Fe / tetrakis[(2-pyridyl)methyl]ethylenediamine was dissolved in 8 g of ethylene glycol, 10 g of hydrated magnesium silicate and 120 g of deionized water were added and stirred for 10 hours to obtain a modified magnesium silicate solution.

[0030] (2) Preparation of modified calcium-silicon aqueous solution: 0.8g nano-titanium dioxide (20nm) is suspended in 200g water, at 60 ℃, begin to drop the silica sol (pH 100g of calcium acetate aqueous solution 100g of mass concentration 15% and mass concentration 28%) 2.7) 150g, were added dropwise for 12h to obtain a modified calcium-silicon aqueous solution.

[0031] (3) Preparation of telechelic polymer: After adding 0.004mol triallyl cyanurate and 0.005mol sodium methoxide into the reaction kettle, vacuumize, replace with nitrogen, heat to 130°C, and then continuously add 1mol Ethylene oxide and 0.3mol propylene oxide were ...

example 3

[0034] (1) Preparation of modified magnesium silicate solution: under nitrogen protection, 0.2g (C 5 h 5 ) 2 Fe / pentamethyldiethylenetriamine was dissolved in 11 g of ethylene glycol, 10 g of hydrated magnesium silicate and 180 g of deionized water were added and stirred for 3 hours to obtain a modified magnesium silicate solution.

[0035] (2) Preparation of modified calcium-silicon aqueous solution: 0.5g nano-titanium dioxide (15nm) is suspended in 230g water, at 80 ℃, begin to drop the silica sol (pH 100g of calcium nitrate aqueous solution 100g of mass concentration 17.2% and mass concentration 30%) 3.8) 120g, were added dropwise for 8h to obtain a modified calcium-silicon aqueous solution.

[0036] (3) Preparation of telechelic polymer: After adding 0.004mol trimethylcyanurate and 0.005mol potassium hydroxide to the reaction kettle, vacuumize, replace with nitrogen, heat to 150°C, and then continuously add 1mol Ethylene oxide and 0.3mol propylene oxide were subjected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com