Cobaltosic oxide quantum dot@carbon composite electrode material and preparation method thereof

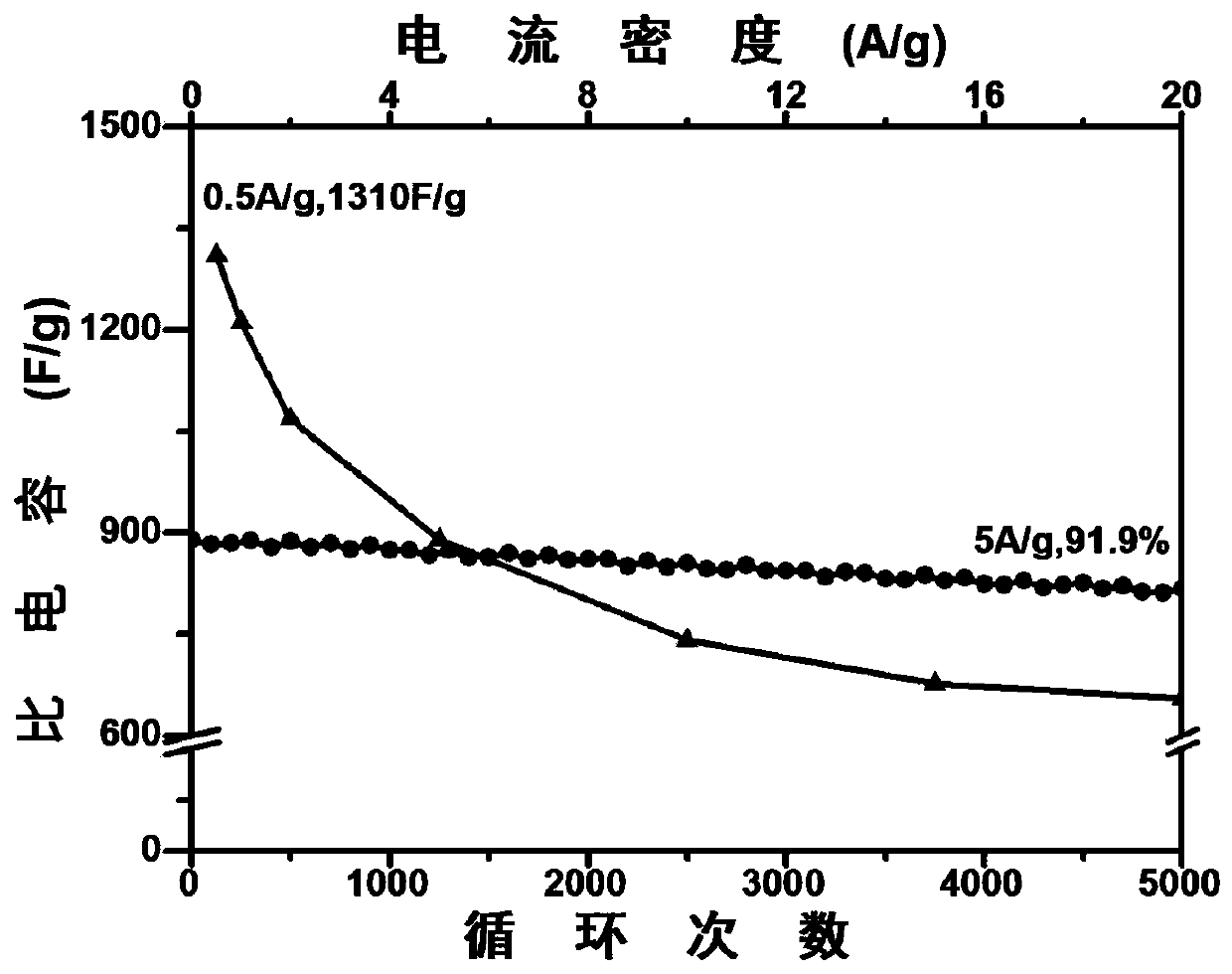

A quantum and electrode material technology of cobalt trioxide, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. Improve stability and increase the effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of cobalt trioxide quantum dot@carbon composite electrode material, comprising the following steps:

[0026] A) mixing and grinding the carbon material and the cobalt salt to obtain a mixed powder, the melting point of the cobalt salt being lower than the thermal decomposition temperature;

[0027] B) Under the condition of protective atmosphere, the mixed product is heated and melted, and then the temperature is continued to be pyrolyzed to obtain tricobalt tetroxide quantum dots@carbon composite electrode material.

[0028] The invention uses carbon materials and cobalt salts as raw materials for preparing carbon materials.

[0029] Wherein, the melting point of the cobalt salt is required to be lower than the thermal decomposition temperature. In the present invention, the cobalt salt is selected from one or more of cobalt nitrate hexahydrate, cobalt acetate and cobalt oxalate.

[0030] In the present invention, the prepa...

Embodiment 1

[0053] Weigh 3g of phosphoric acid and dissolve it in 200g of deionized water, stir in a 90°C water bath, then slowly add 4g of melamine powder and mix evenly, the solution gradually changes from a milky white suspension to a colorless transparent liquid. After the above liquid was continuously heated and stirred to anhydrous state, the mixture was transferred to a blast furnace at 80° C. for drying overnight. The dried white powder was transferred to an alumina crucible, and annealed in a tube furnace from room temperature to 900 °C for 2 h with Ar gas as a protective gas at a heating rate of 5 °C per minute to obtain a base carbon material.

[0054] Weigh 90mg of cobalt nitrate hexahydrate and 100mg of base carbon material into an agate mortar and grind evenly for 10 minutes to obtain a mixed black powder. Transfer the black powder to a polytetrafluoroethylene container, seal the container with a sealing film, and then transfer it to a tube In an Ar atmosphere, the temperatu...

Embodiment 2

[0060] The base carbon material was prepared according to the method of Example 1, and 180 mg of cobalt nitrate hexahydrate and 100 mg of base carbon material were weighed and added to an agate mortar for uniform grinding for 10 minutes to obtain a mixed black powder. Transfer the black powder to a polytetrafluoroethylene container, Seal the container with a parafilm, then transfer it to a tube furnace, slowly raise the temperature from room temperature to 60°C at a rate of 2°C per minute under an Ar atmosphere and keep it warm for 2 hours, and then heat it to 450°C at a rate of 5°C per minute. ℃, kept for 6 hours, dissolved the pyrolysis product in nitric acid solution and ultrasonicated for 10 minutes, and then washed with deionized water repeatedly for 3 times to obtain cobalt tetraoxide quantum dots@carbon composite material.

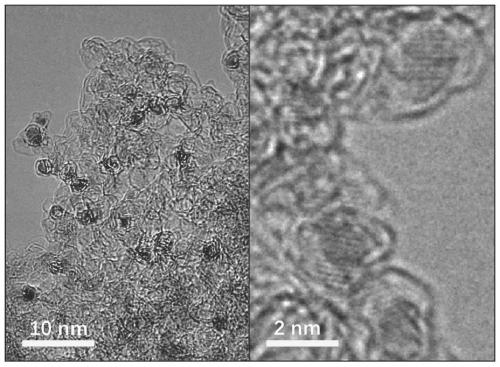

[0061] The composite material prepared in Example 2 of the present invention is carried out transmission electron microscopy detection, such as fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com