Method for treating oxygen-containing tail gas in ethylene glycol production device

A production device and treatment method technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve the problems of high cost, low safety, and environmental pollution of oxygen-containing tail gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

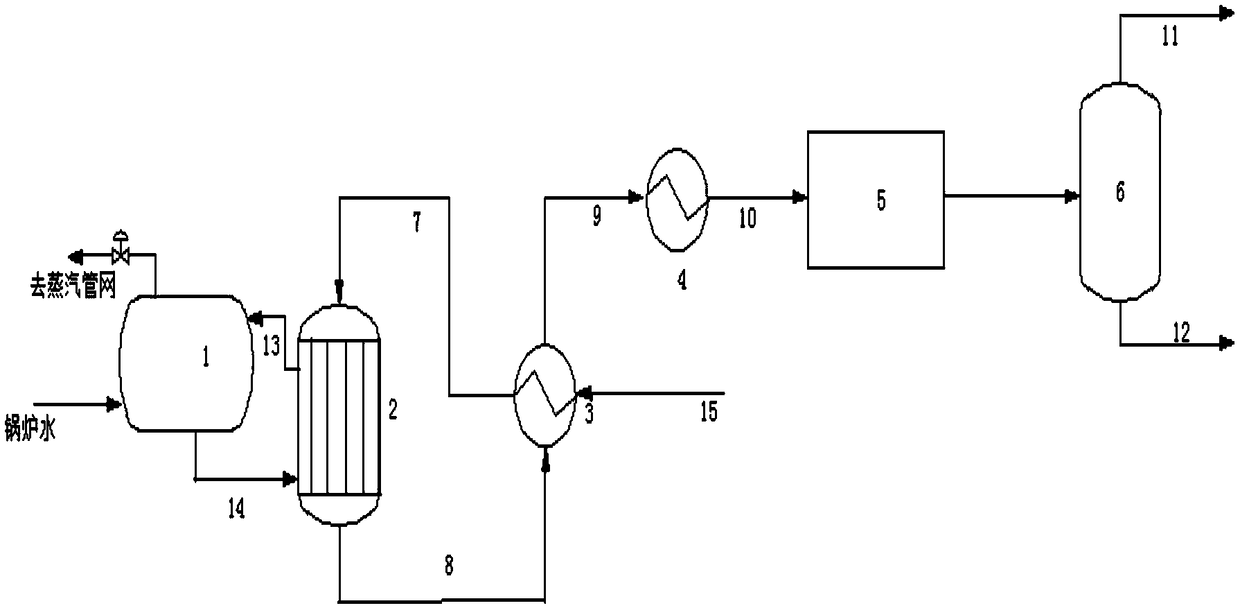

[0025] A treatment method for oxygen-containing tail gas in an ethylene glycol production unit, such as figure 1 As shown, the oxygen-containing tail gas 15 enters the tubular reactor 2 through the gas-gas heat exchanger 3, and under the action of a noble metal catalyst such as silver or platinum, a catalytic oxidation reaction occurs on the side of the tube, so that the oxygen in the tail gas and ethylene fully react , The heat produced by the tubular reactor 2 is sent out through the steam drum 1. In addition, the reaction temperature of the catalytic oxidation is controlled by the pressure of the deheated steam drum 1. The treated tail gas 9 is cooled by the cooler 4 and enters the ethylene recovery unit 5, and the tail gas from which ethylene has been removed enters the liquid separation tank 6 for subsequent treatment.

[0026] The temperature of the oxygen-containing tail gas is 25.2°C, and the mass flow rate is 2397.72kg / hr. In terms of volume fraction, the oxygen conte...

Embodiment 2

[0029] According to the conditions and steps described in Example 1, the oxygen-containing tail gas temperature is 25.2°C, and the mass flow rate is 599.43kg / hr, wherein, in terms of volume fraction, the oxygen content is 5.1%, the ethylene content is 33.9%, the methane content is 52.8%, and the carbon dioxide content is 1.5% %, the content of argon is 6.2%, the content of nitrogen is 0.2%, and the content of water is 0.3%. Sent, in addition, the reaction temperature of catalytic oxidation process is controlled by the pressure of deheating steam drum, reaction temperature 350 ℃, reaction pressure 1.5MPa (gauge pressure), in silver catalyst (catalyst loading is 0.1998kg, the loading capacity of silver in the catalyst 3.4% (mass), the carrier is SiO 2 ) under the action of a catalytic oxidation reaction, so that the oxygen in the tail gas fully reacts with ethylene, the conversion rate of oxygen reaches 100%, and generates carbon dioxide and water, that is, the volume content of...

Embodiment 3

[0032] According to the conditions and steps described in Example 1, the oxygen-containing tail gas temperature is 25.2°C, and the mass flow rate is 2397.72kg / hr, wherein, in terms of volume fraction, the oxygen content is 3.5%, the ethylene content is 41.49%, the methane content is 46.53%, and the carbon dioxide content is 2.1% %, the content of argon is 5.8%, the content of nitrogen is 0.18%, and the content of water is 0.4%. Sent, in addition, the reaction temperature of catalytic oxidation process is controlled by the pressure of deheating steam drum, reaction temperature 350 ℃, reaction pressure 1.5MPa (gauge pressure), in silver catalyst (catalyst loading is 0.79924kg, the loading capacity of silver in the catalyst 3.4% (mass), the carrier is SiO 2 ) under the action of a catalytic oxidation reaction, so that the oxygen in the tail gas fully reacts with ethylene, the conversion rate of oxygen reaches 100%, and generates carbon dioxide and water, that is, the volume conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com