Method for preparing sodium-zirconium-silicon-phosphorus compound solid electrolyte

A solid electrolyte, solid electrolyte membrane technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of high cost, complex preparation process of solid phase method, good performance, etc. Battery preparation, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

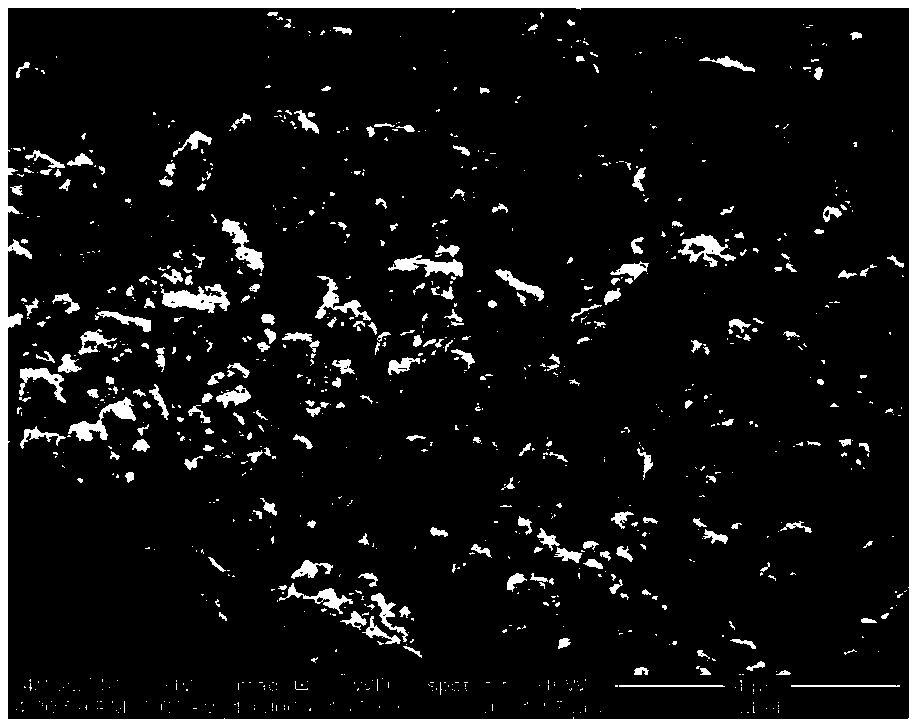

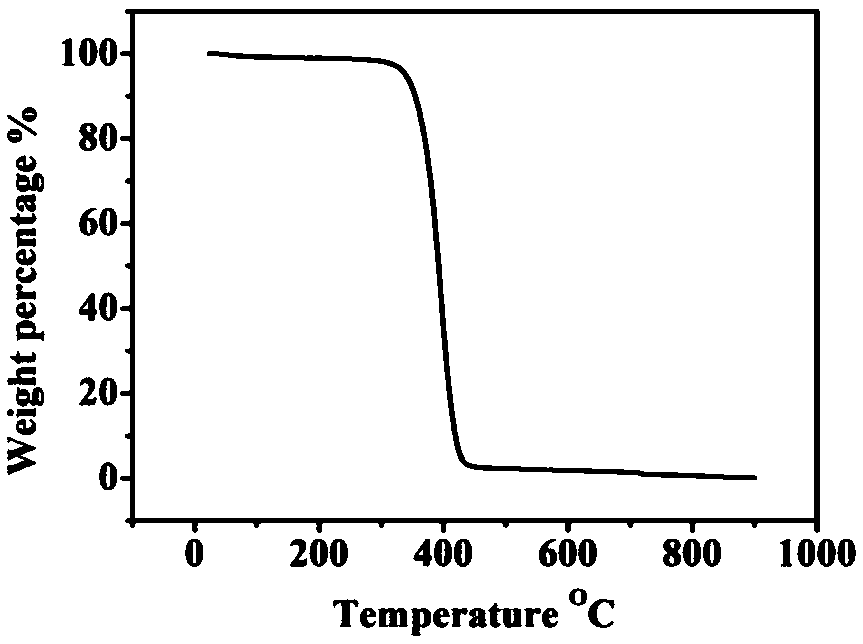

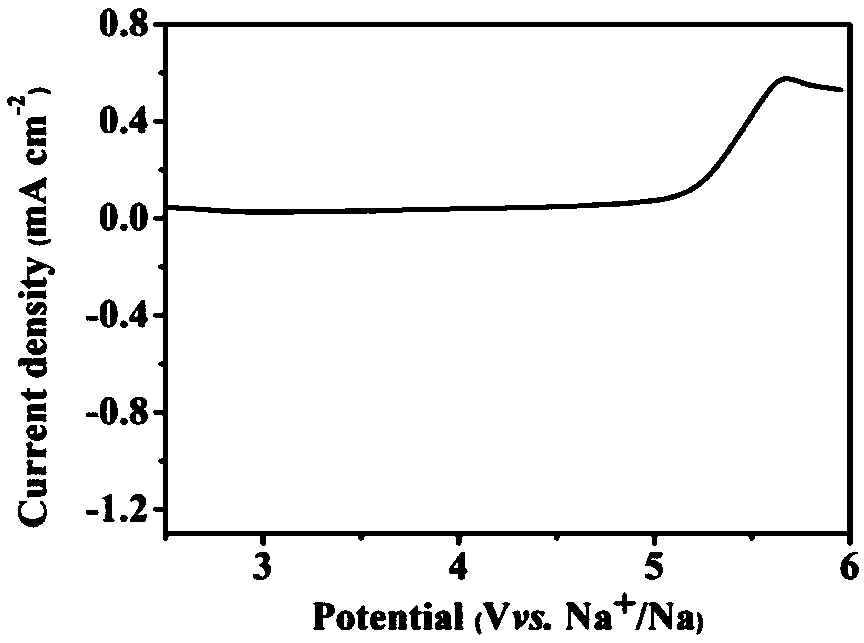

Image

Examples

example 1

[0037] Example 1 uses nitrate and glycine as raw materials without any pretreatment. First weigh 15.4mmol of lithium nitrate, 6mmol of lanthanum nitrate, 4mmol of zirconium nitrate, 0.48mmol of aluminum nitrate and 12.94mmol of glycine, dissolve them in deionized water, put them on an electric furnace, and heat until the combustion synthesis reaction occurs after evaporation to obtain white fluffy Powder material. The powder material was heated in a muffle furnace at 900° C. for 4 hours to obtain cubic phase lithium lanthanum zirconium oxide. The obtained cubic phase lithium lanthanum zirconium oxide was ball milled at a rotational speed of 300 r / min for 10 h to obtain cubic phase lithium lanthanum zirconium oxide nanopowder. The monomers polyethylene glycol diacrylate and polyethylene glycol diglycidyl ether are polymerized by adding 1wt% benzoyl peroxide, adding lithium bistrifluoromethanesulfonamide, stirring evenly and adding 10wt% lithium lanthanum Zirconium oxide powder ...

example 2

[0038] Example 2 uses nitrate and urea as raw materials without any pretreatment. First weigh 15.4mmol of lithium nitrate, 6mmol of lanthanum nitrate, 4mmol of zirconium nitrate, 0.48mmol of aluminum nitrate and 15mmol of urea, dissolve them in deionized water, place them on an electric furnace, and heat until the combustion synthesis reaction occurs after evaporation to obtain white fluffy powder body material. The powder material was cold-pressed at 200MPa into a disc with a diameter of 15mm, and then heated in a muffle furnace at 700°C for 4h to obtain the cubic phase lithium lanthanum zirconium oxide. The obtained cubic phase lithium lanthanum zirconium oxide was ball milled for 15 hours at a speed of 300 r / min to obtain lithium lanthanum zirconium oxide nanopowder. 0.1 wt% benzoyl peroxide was dissolved in 20 g of butyl acrylate, and stirred at 85°C until a uniform solution was formed. polyethylene glycol diacrylate

[0039] 5wt%, 10wt%, 15wt%, 20wt% mass fraction mixe...

example 3

[0040] Example 3 uses nitrate and glycine as raw materials without any pretreatment. First weigh 15.4mmol of lithium nitrate, 6mmol of lanthanum nitrate, 4mmol of zirconium oxynitrate, 0.48mmol of aluminum nitrate and 10mmol of glycine and dissolve them in deionized water. Powder material. The powder material was cold pressed into a disc with a diameter of 10 mm at 200 MPa, and then heated in a muffle furnace at 800 ° C for 4 h to obtain a cubic phase lithium lanthanum zirconium oxide. The obtained cubic phase lithium lanthanum zirconium oxide was ball milled for 10 h at a ball milling speed of 300 r / min to obtain lithium lanthanum zirconium oxide nanopowder. Polylactic acid polyethylene glycol diacrylate according to the mass ratio of 95 / 5, 90 / 10, 85 / 15, 80 / 20 and 75 / 25, after stirring evenly at 170°C, add 20wt% lithium lanthanum zirconium oxide powder, Stirring for 30 minutes, standing for 2 hours for in-situ cross-linking reaction to obtain a ceramic-cross-linked polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com