Preparation method for natural basin-based bionic structure bone scaffold

A natural protein and structural bone technology, which is applied in the field of preparation of natural protein-based biomimetic structural bone scaffolds, can solve the problem of complete repair and reconstruction of defect areas that are difficult to achieve osseointegration, unfavorable cell communication and information transmission, and cell growth and migration. Limitation and other issues, to achieve the effect of low price, huge development potential and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned composite porous material, the steps are as follows:

[0036] (1) Preparation of wool keratin by ion precipitation method;

[0037] (2) Preparation of silk fibroin by high-pressure boiling method;

[0038] (3) Two natural protein solutions were mixed and stirred to prepare natural protein-based biomimetic structural bone scaffolds.

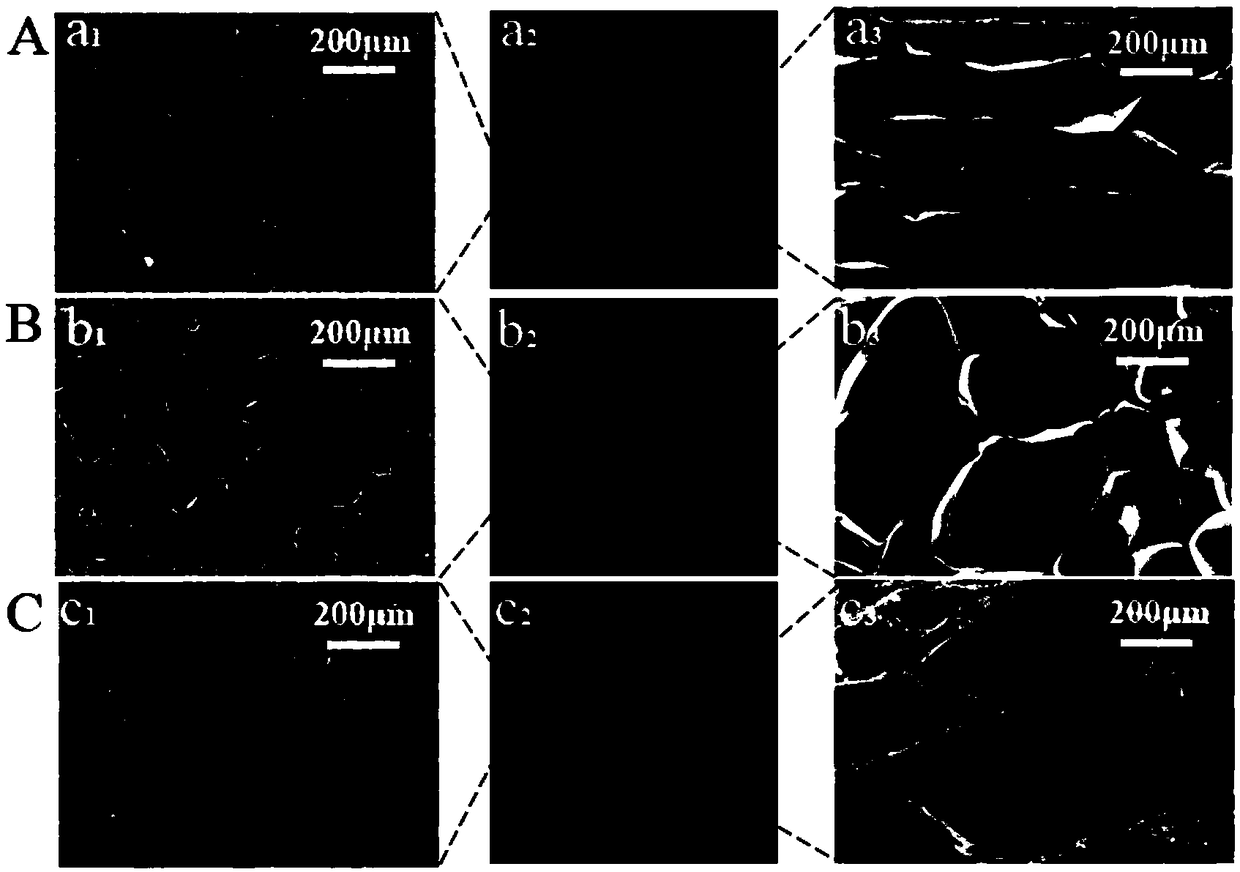

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0040] A method for preparing a natural protein-based biomimetic structure bone scaffold, comprising:

[0041] Step 1, preparation of wool keratin by ion precipitation method:

[0042] The raw wool was immersed in a 2% NaOH solution in a constant temperature water bath. After the wool fibers were completely dissolved, the hydrolyzed solution was kep...

Embodiment 1

[0051] This implementation case shows a preparation method of a natural protein-based biomimetic structure bone scaffold, including:

[0052] (1) Alkaline method to prepare wool protein: use 1%~5% NaOH solution to dissolve a certain amount of wool fiber, filter it, and then use a dialysis bag with a molecular weight cut-off of 2000Da~20000Da for dialysis for 1~5 days , after concentration of a 15% polyethylene glycol (PEG) solution with a molecular weight of 20,000 for 12-24 hours, a wool protein solution with a mass fraction of 3-10% is obtained.

[0053] (2) Preparation of silk fibroin by high-pressure water boiling: degumming and dissolving natural silk, dialysis and centrifugation according to the method in step (1), and concentration of 15% PEG solution with a molecular weight of 20,000 for 6-12 hours to obtain The mass fraction is 10-20% silk fibroin solution.

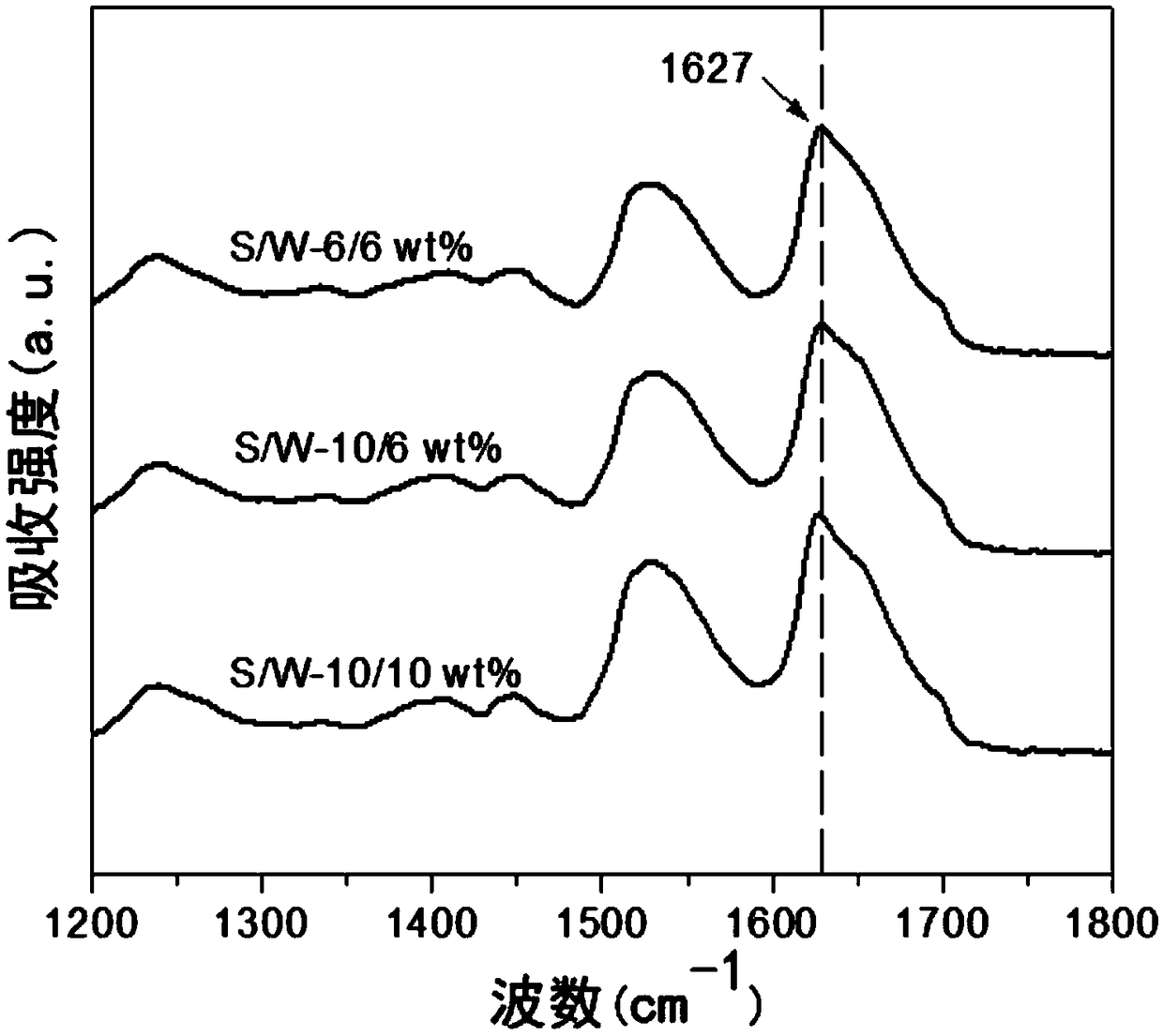

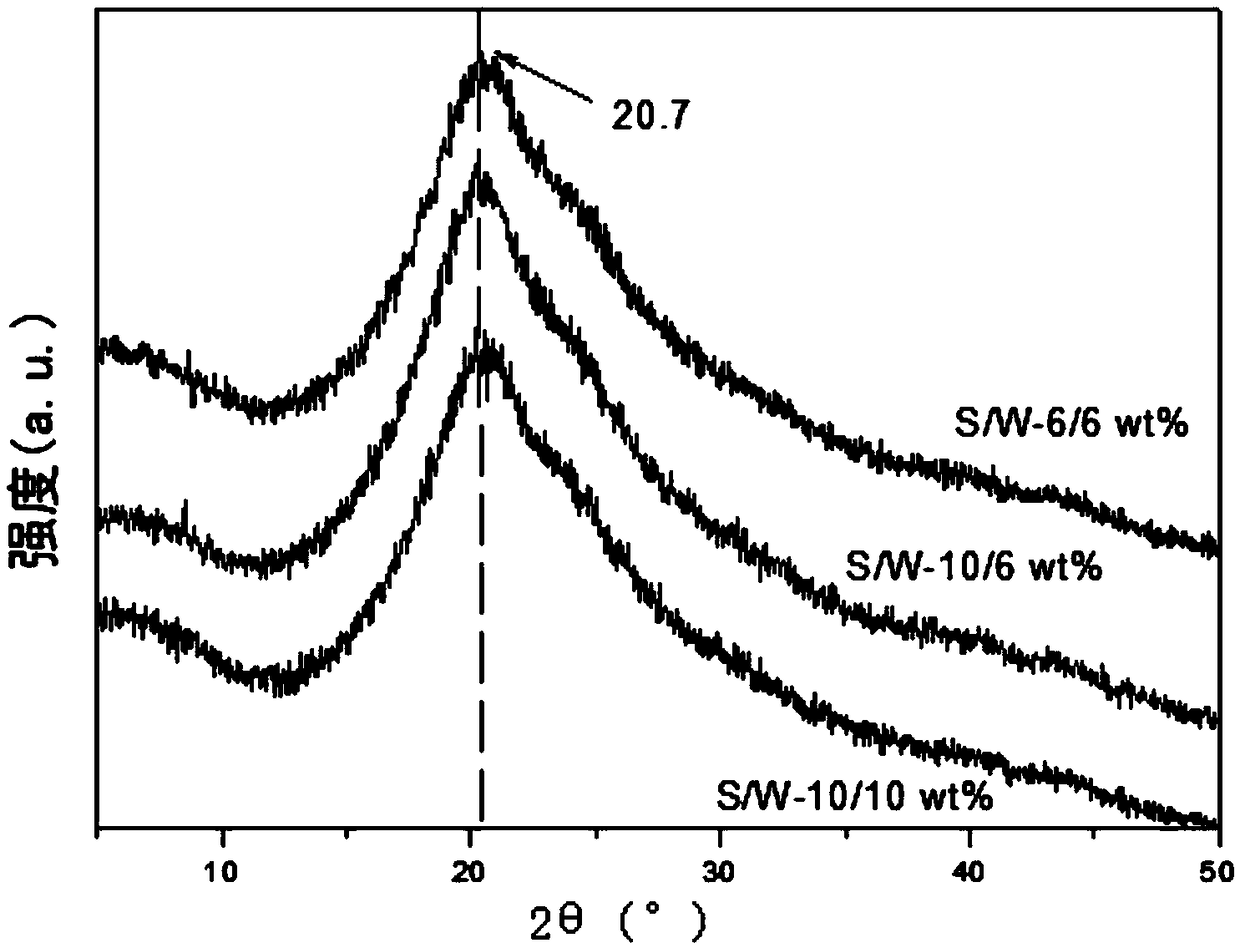

[0054] (3) Mixing method of two natural protein solutions: Measure a certain amount of silk fibroin solution ...

Embodiment 2

[0057] This implementation case shows a preparation method of a natural protein-based biomimetic structure bone scaffold, including:

[0058] (1) Wool protein was prepared by reduction method: 7M urea, 0.08M Na 2 S and 0.8g sodium dodecyl sulfate (SDS) were prepared into 100 mL solution, then 5g of wool fiber was added, and the water bath temperature was 50°C for 8h water bath treatment, followed by filtration, and then carried out with a dialysis bag with a molecular weight cut-off of 2000Da~20000Da Dialysis, dialysis for 1-5 days, after concentration of 15% polyethylene glycol (PEG) solution with a molecular weight of 20,000 for 12-24 hours, a wool protein solution with a mass fraction of 3-10% was obtained.

[0059] (2) Preparation of silk fibroin by high-pressure water boiling: degumming and dissolving natural silk, dialysis and centrifugation according to the method in step (1), and concentration with a 15% PEG solution with a molecular weight of 20,000 to obtain a mass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com