PH (potential of hydrogen) responsive magnetic meso-porous silicon nano-particle drug controlled release system and preparation method thereof

A nanoparticle, drug controlled release technology, applied in the direction of pharmaceutical formulation, drug combination, drug delivery, etc., can solve the impact of MRI imaging, stop in vitro test and animal test, dispersion, stability, biocompatibility, lack of biological toxicity Evaluation system and other issues to achieve the effect of increasing targeting, reducing toxic and side effects, and achieving the best therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

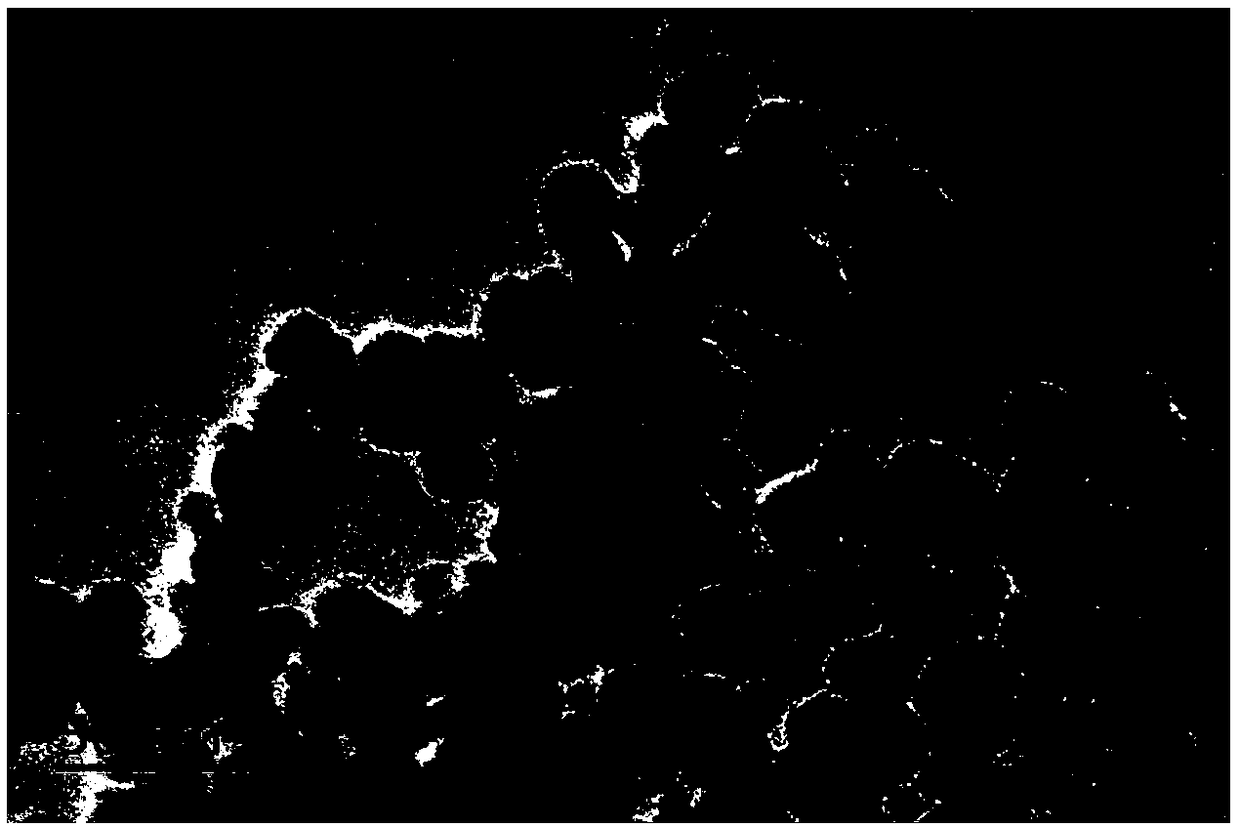

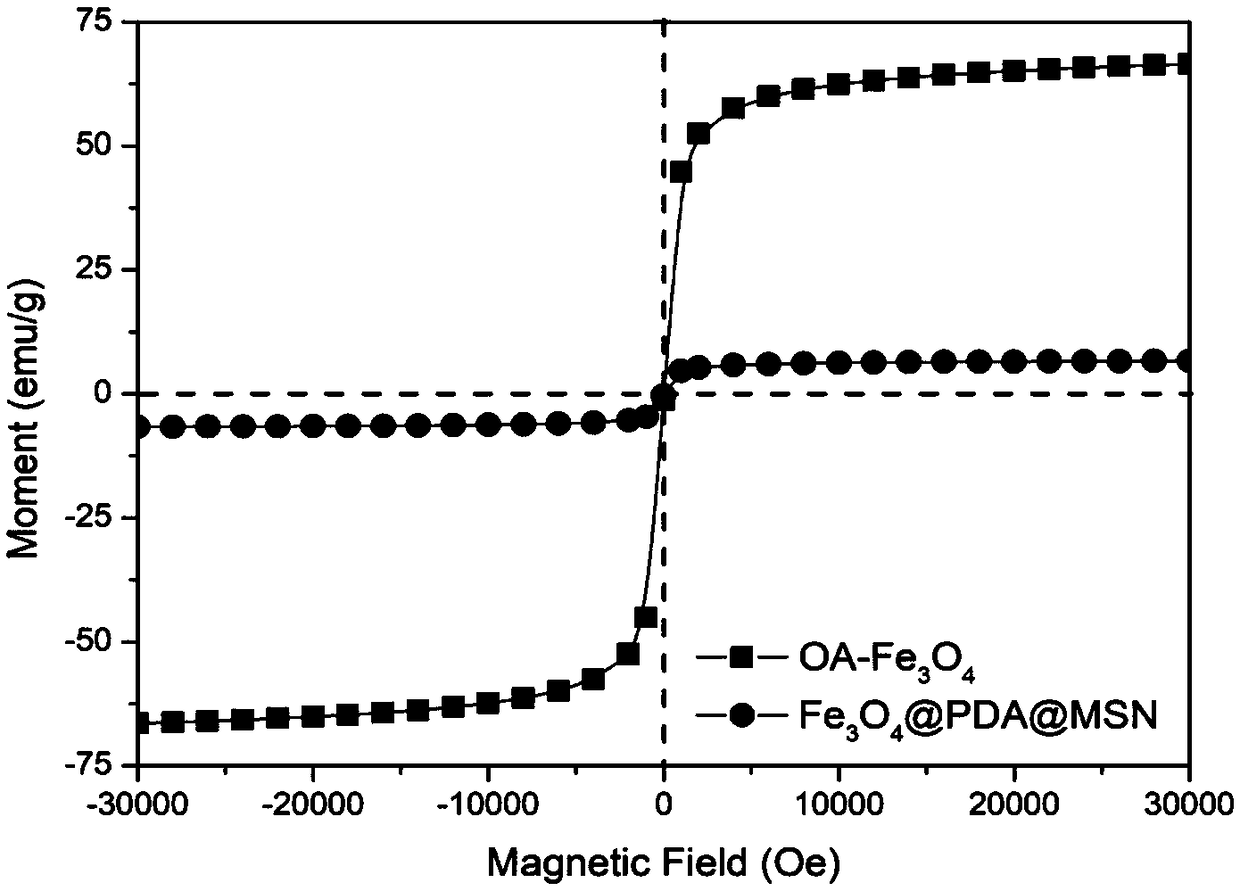

[0072] 1. Preparation of Fe3O4 nanoparticles (OA-Fe3O4)

[0073] The preparation steps of OA-Fe3O4 are as follows: 13.12g FeCl3·6H2O and 6.65g FeCl2·4H2O were sequentially dissolved in 80mL deionized water, heated to 80°C under nitrogen atmosphere, and vigorously stirred for 0.5h. Then 45 mL of NH3·H2O solution (25 wt%) was added dropwise, the resulting suspension was vigorously stirred for 5 min, then 2 mL of oleic acid was added, and the reaction was allowed to continue stirring for 25 min. The resulting crude product was separated by magnet to give a colorless solution in the upper layer and a tarry black magnetic gel precipitated. The magnetic gel is repeatedly washed with deionized water and ethanol, and then dried in a vacuum drying room to obtain oleic acid-stabilized ferric oxide nanoparticles (OA-Fe3O4).

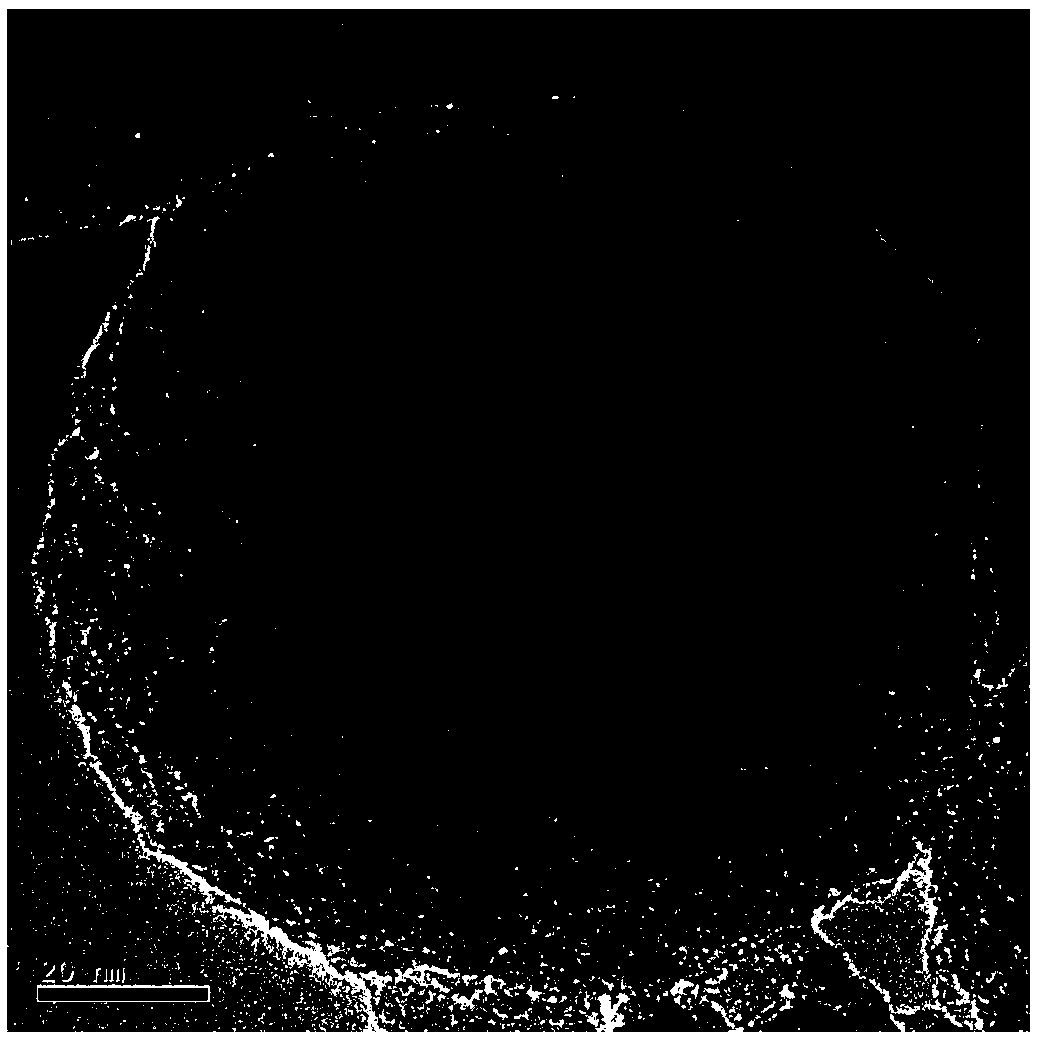

[0074] 2. Preparation of Magnetic Mesoporous Silicon Nanoparticles (CTAB-MMSN)

[0075] Disperse 7.5 mg of OA-Fe3O4 in 0.5 mL of chloroform, then add to 5 mL of d...

Embodiment 2

[0093] 1. Preparation of Fe3O4 nanoparticles (OA-Fe3O4)

[0094] The preparation steps of OA-Fe3O4 are as follows: 13.67g FeCl3·6H2O and 7.32g FeCl2·4H2O were sequentially dissolved in 90mL deionized water, heated to 80°C under nitrogen atmosphere, and vigorously stirred for 0.5h. Then 50 mL of NH3·H2O solution (25 wt%) was added dropwise, the resulting suspension was vigorously stirred for 5 min, then 2 mL of oleic acid was added, and the reaction was allowed to continue stirring for 25 min. The resulting crude product was separated by magnet to give a colorless solution in the upper layer and a tarry black magnetic gel precipitated. The magnetic gel is repeatedly washed with deionized water and ethanol, and then dried in a vacuum drying room to obtain oleic acid-stabilized ferric oxide nanoparticles (OA-Fe3O4).

[0095] 2. Preparation of Magnetic Mesoporous Silicon Nanoparticles (CTAB-MMSN)

[0096] Disperse 7.5 mg of OA-Fe3O4 in 0.5 mL of chloroform and then add to 5 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com