Platinum nanoparticle loaded mesoporous zirconia nanotube composite material, preparation method and application thereof in continuous treatment of organic waste gas

A technology of mesoporous zirconia and composite materials, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of inability to expose active sites, insufficient specific surface area of carriers, and uneven distribution of platinum nanoparticles. Achieve high-efficiency catalytic oxidation of organic waste gas, excellent performance in treating organic waste gas, and the effect of promoting catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

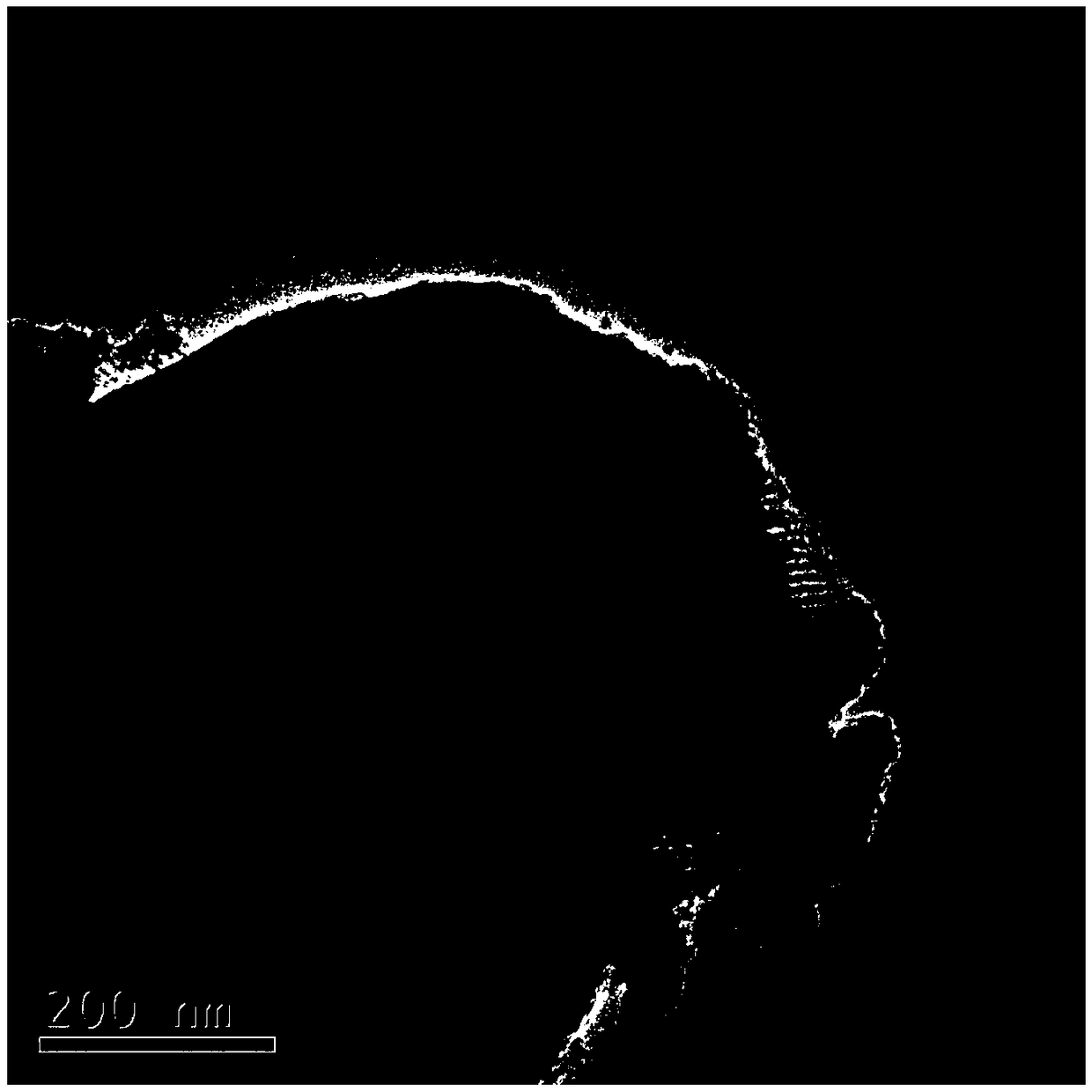

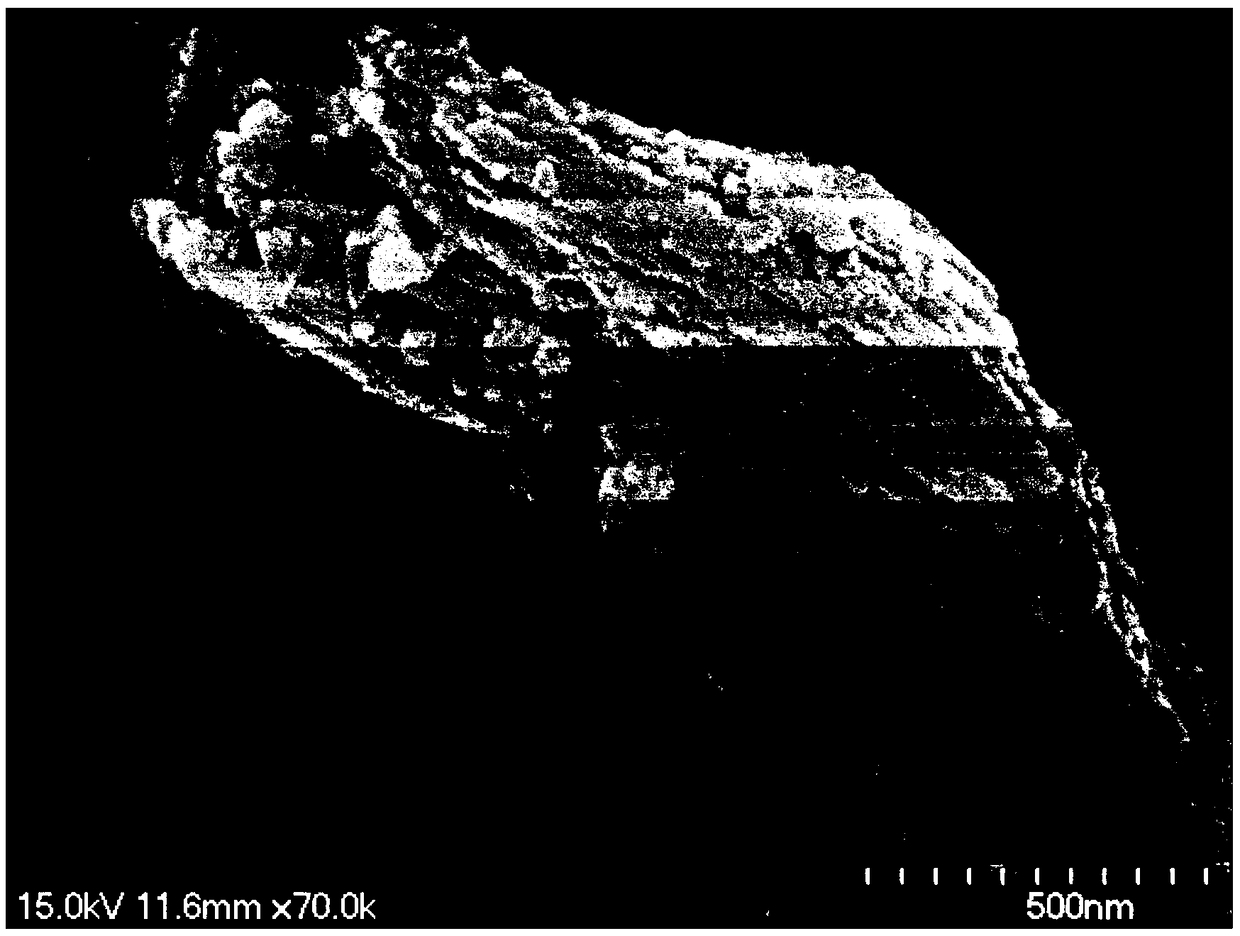

[0044] Loading platinum nanoparticles mesoporous zirconia nanotubes, the specific steps are as follows:

[0045] Mix 4.00 g of P123, 130 ml of ultrapure water, 20 ml of concentrated hydrochloric acid and 8.32 g of tetraethyl orthosilicate, stir at 38°C for 24 hours, react with water at 110°C for 24 hours, filter with suction, wash and dry. The resulting precipitate was mixed with 120 ml of concentrated nitric acid (65wt%), 40 ml of H 2 o 2 Place in a 1-liter flask, reflux at 80°C for 3 hours, cool down naturally, and filter the mixture with suction to obtain a template agent, rinse with ultrapure water and ethanol several times until neutral, and dry at 50°C.

[0046] Prepare 10g / L of chloroplatinic acid (H 2 PtCl 6 •6H 2 O) solution and 1.07mol / L dilute hydrochloric acid, take 2.00 grams of template agent, 1.878 grams of zirconium oxychloride (ZrOCl 2 •8H 2 O), 3 milliliters of dilute hydrochloric acid and a certain amount (the amount of chloroplatinic acid solution tha...

Embodiment 2

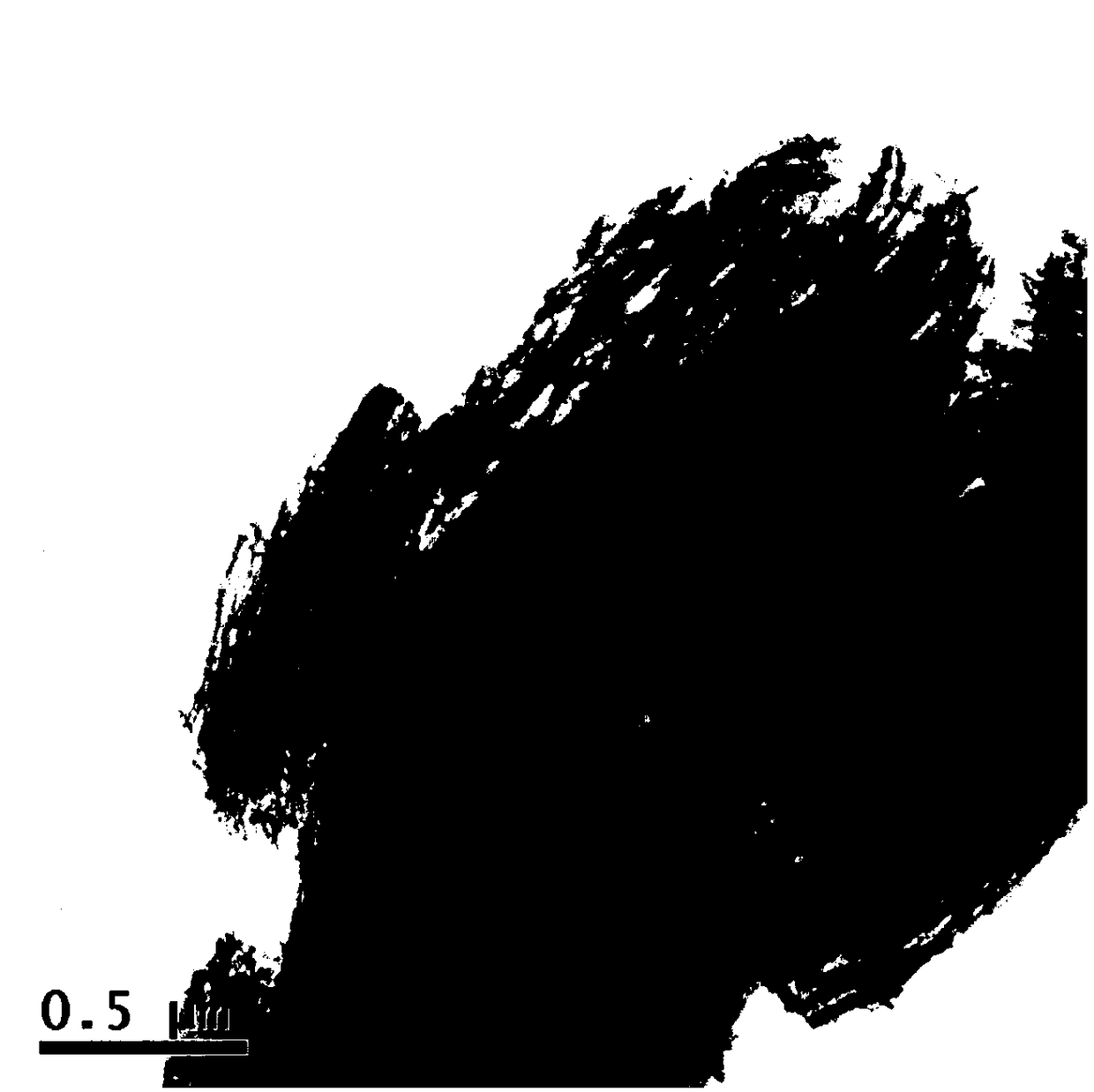

[0049] The platinum nanoparticle-loaded mesoporous zirconia nanotubes were made into airgel and MOF-5 was modified on its surface. The specific steps are as follows:

[0050] Take 50 mg of graphene oxide, ultrasonically disperse it in 10 ml of ultrapure water, add a certain amount of catalyst (10 mg, 20 mg, 30 mg), after the dispersion is uniform, then add 100 mg of L-ascorbic acid, after the dissolution is complete , reacted in a water bath at 100°C for 30 minutes, then directly frozen at -40°C for 1 hour, took it out and bathed it in a water bath at 100°C for 8 hours, sucked out the excess water in the container with a straw after the reaction, and finally freeze-dried to obtain an airgel .

[0051] Carboxylation reaction is carried out on the prepared graphene airgel first. Soak the airgel in 1ml of KH550 (3-aminopropyltriethoxysilane) / 10ml of ethanol, place it on a shaker for 8 hours, then dissolve 0.50g of succinic anhydride in 10ml of DMF to prepare solution, use this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com