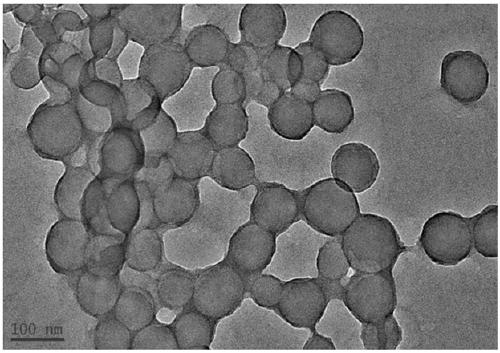

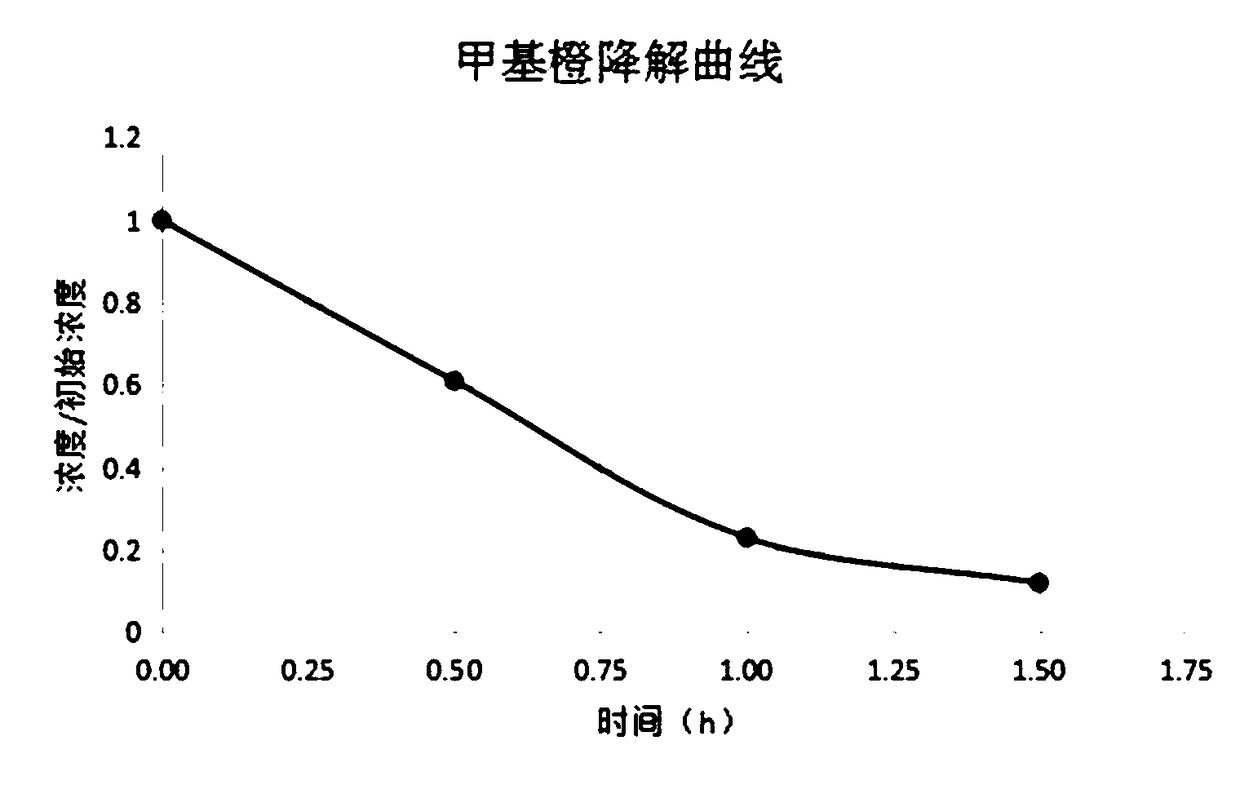

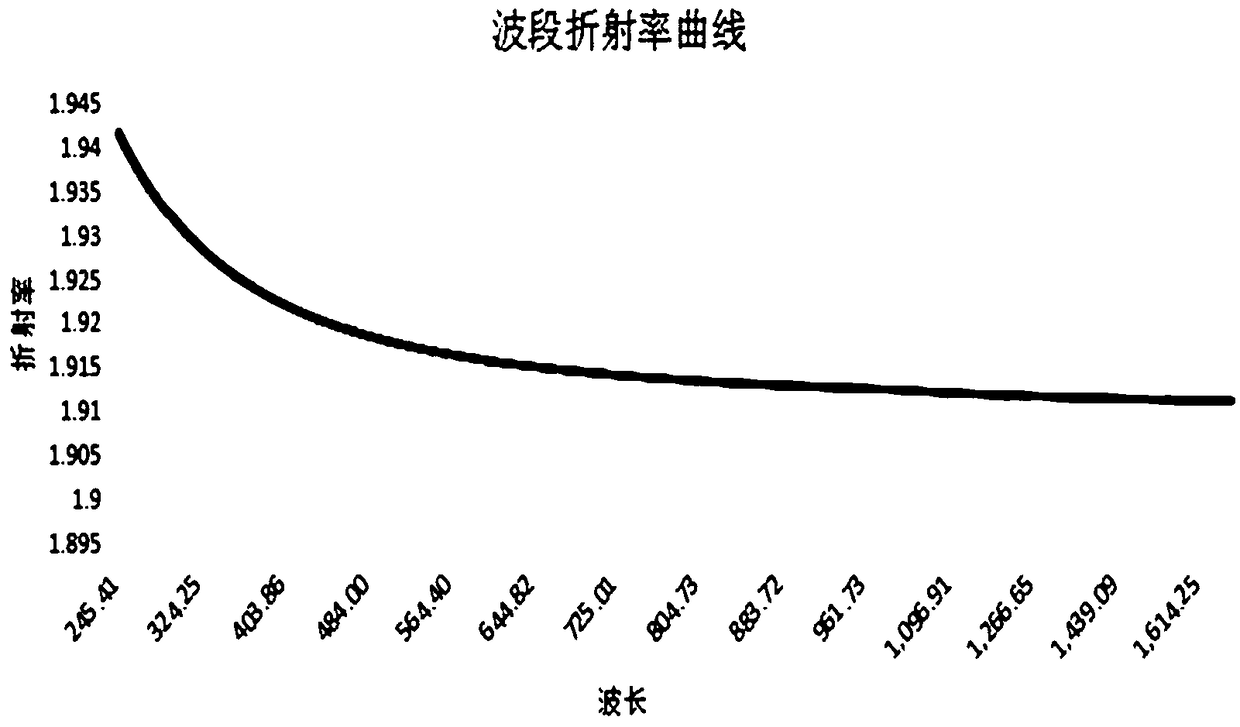

Nanometer hollow titanium dioxide microsphere with low reflection index and high catalysis activity and preparation method thereof

A technology with high catalytic activity and low refractive index, applied in the field of nanometer hollow titanium dioxide microspheres and their preparation, can solve the problems affecting the morphology, adhesion deformation, low refractive index and the like of nanometer core-shell titanium dioxide microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The nano-titania hollow microspheres with low refractive index and high catalytic activity of this embodiment are prepared by the following steps (the following components are all calculated by mass percentage):

[0040] Step a. Add 73.4% water into the reaction vessel, turn on stirring and heating, when the temperature rises to 85°C, add 2% ammonium persulfate initiator solution, after the temperature stabilizes, start adding 18% styrene, 0.6% of divinylbenzene, 2% of cationic monomer acryloxyethyl trimethoxyammonium chloride and 4% of zwitterionic reactive emulsifier SM-JR-1, added within 6h to complete the reaction, and heat preservation 10h; After the heat preservation is completed, the temperature is reduced to 30°C, the auxiliary ammonia water is added to neutralize, the pH value is adjusted to 8, and then the cationic polystyrene emulsion is obtained after filtration;

[0041] Step b. Mix 5% cationic polystyrene emulsion and 81% solvent methanol uniformly, and mix 12%...

Embodiment 2

[0045] The nano-titania hollow microspheres with low refractive index and high catalytic activity of this embodiment are prepared by the following steps (the following components are all calculated by mass percentage):

[0046] Step a. Add 64% water to the reaction vessel, turn on the stirring and heating, when the temperature rises to 135°C, add 2% potassium persulfate and 3% sodium persulfate initiator solution, and when the temperature stabilizes, start adding 20% styrene, 1% divinylbenzene, cationic monomer 4% methacryloxyethyl trimethyl ammonium chloride and 1% acrylamidopropyl trimethyl ammonium chloride, and 5% The zwitterionic reactive emulsifier SM-JR-1 was added within 4h, and the reaction was incubated for 6h; after the incubation, the temperature was lowered to 33°C, the auxiliary diethanolamine was added to neutralize, the pH was adjusted to 7, and then filtered. To obtain a cationic polystyrene emulsion;

[0047] Step b. Mix 2% cationic polystyrene emulsion and 87% s...

Embodiment 3

[0050] The nano-titania hollow microspheres with low refractive index and high catalytic activity of this embodiment are prepared by the following steps (the following components are all calculated by mass percentage):

[0051] Step a. Add 87.4% water to the reaction vessel, start stirring and heating, when the temperature rises to 60°C, add 0.5% benzoyl peroxide initiator solution, and when the temperature stabilizes, start adding 10% benzene Ethylene, 0.1% divinylbenzene, cationic monomer 0.5% benzyl vinyl trimethyl ammonium chloride and 0.5% methacryloxyethyl dimethyl benzyl ammonium chloride, and 1% amphoteric The ion-reactive emulsifier SM-JR-1 was added within 8 hours and the reaction was kept for 13 hours; after the incubation, the temperature was lowered to 37°C, and the additives triethanolamine and triethylamine were added for neutralization, and the pH value was adjusted to 4. Then filter to obtain cationic polystyrene emulsion;

[0052] Step b. Mix 10% cationic polysty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com