Efficient conductive agent

A conductive agent and high-efficiency technology, which is applied in the field of battery material preparation, can solve the problems of conductive agents such as the short-term conductive effect, and achieve the effects of facilitating dispersion, improving dispersion, and stabilizing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

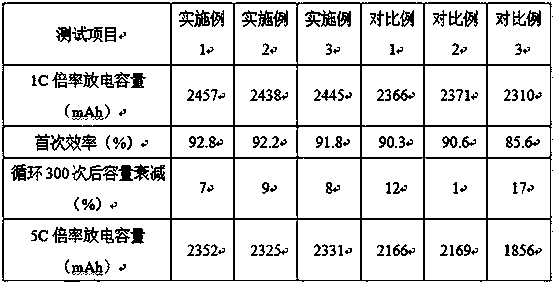

Examples

preparation example Construction

[0032] The preparation method of composite conductive component A comprises the steps:

[0033] (1) Take 4,4΄-diphenylmethane diisocyanate, polypropylene glycol, and N,N΄-dimethylformamide according to the mass ratio of 1:3~6:16 and mix them in a container at 70~85°C at 400~ Stir at 650r / min for 20~45min to obtain the prepolymer, mix and stir the prepolymer and methylfuranamine in an ice-water bath at a mass ratio of 8~15:1, and then heat up to 60~75°C at 3~6°C / min ℃, add bismaleimide with 20~35% of prepolymer mass, mix and stir, keep warm for 20~24h, and obtain self-repairing polyurethane material;

[0034] (2) According to the mass ratio of 1:0.1:12~20, take polyethyleneimine, auxiliary materials, and water, mix and stir, move to an ultrasonic oscillator and disperse ultrasonically at a frequency of 45~55kHz for 25~40min to obtain a dispersion, and take the dispersion according to its mass Add metal filler, pretreated steel slag, and self-repairing polyurethane material at ...

Embodiment 1

[0043] Reagent A: Mix oxalic acid and ethanol solution with a volume fraction of 70% at a mass ratio of 1:12 to obtain Reagent A.

[0044] Reagent B: Mix urea and sodium carbonate solution with a mass fraction of 15% at a mass ratio of 1:10 to obtain reagent B.

[0045] Metal filler: Mix nano-copper wire, flake copper powder, spherical copper powder and Glauber's salt according to the mass ratio of 5:1:4:1 to obtain the metal filler.

[0046] Feed solution: Mix aniline, pyrrole, and PBS buffer solution with a pH of 7.5 at a mass ratio of 4:1:15 to obtain a feed solution.

[0047] Auxiliary materials: Mix microcrystalline paraffin and isocyanate at a mass ratio of 7:1 to obtain auxiliary materials.

[0048] Pretreatment of steel slag: Take steel slag, camellia seed meal, fly ash, and water according to the mass ratio of 10:1:3:25, mix them with 500r / min magnetic force for 40min, filter, take the filter residue in a ball mill tank and mill at 350r / min for 1h, The ball abrasive...

Embodiment 2

[0061] Reagent A: Mix oxalic acid and ethanol solution with a volume fraction of 70% at a mass ratio of 1:15 to obtain Reagent A.

[0062] Reagent B: Mix urea and sodium carbonate solution with a mass fraction of 15% at a mass ratio of 1:13 to obtain reagent B.

[0063] Metal filler: Mix nano-copper wire, flake copper powder, spherical copper powder and Glauber's salt according to the mass ratio of 5:2:4:1 to obtain the metal filler.

[0064] Feed solution: Mix aniline, pyrrole, and PBS buffer solution with a pH of 7.8 at a mass ratio of 4:2:20 to obtain a feed solution.

[0065] Auxiliary materials: Mix microcrystalline paraffin and isocyanate at a mass ratio of 7:2 to obtain auxiliary materials.

[0066] Steel slag pretreatment: take steel slag, camellia oleifera seed meal, fly ash, and water in a mass ratio of 12:1:3:25, mix them with magnetic force at 700r / min for 50min, filter, take the filter residue in a ball mill tank and mill at 450r / min for 2h, The ball abrasive is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com