Preparing method and application of loading type gold catalyst

A gold catalyst and supported technology, applied in the field of supported gold catalyst and its preparation, can solve the problems of narrow distribution, poor repeatability, low gold utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Specifically, the present invention provides a method for preparing a supported gold catalyst for the direct gas-phase epoxidation of propylene to prepare propylene oxide by means of an impregnation method. The method comprises the steps of:

[0031] In the first step, the gold precursor solution is mixed with a titanium-containing carrier and dried to obtain a solid sample;

[0032] In the second step, the solid sample is subjected to high-temperature treatment in a certain atmosphere to obtain a supported gold catalyst.

[0033] In one embodiment of the present invention, the gold precursor solution used in the above-mentioned first step is formed by mixing the gold precursor with a solvent; the gold precursor includes chloroauric acid or its derivatives, inorganic gold compounds and Organogold compounds.

[0034] In one embodiment of the present invention, said chloroauric acid derivatives include one or more of cesium chloroaurate, potassium chloroaurate, sodium c...

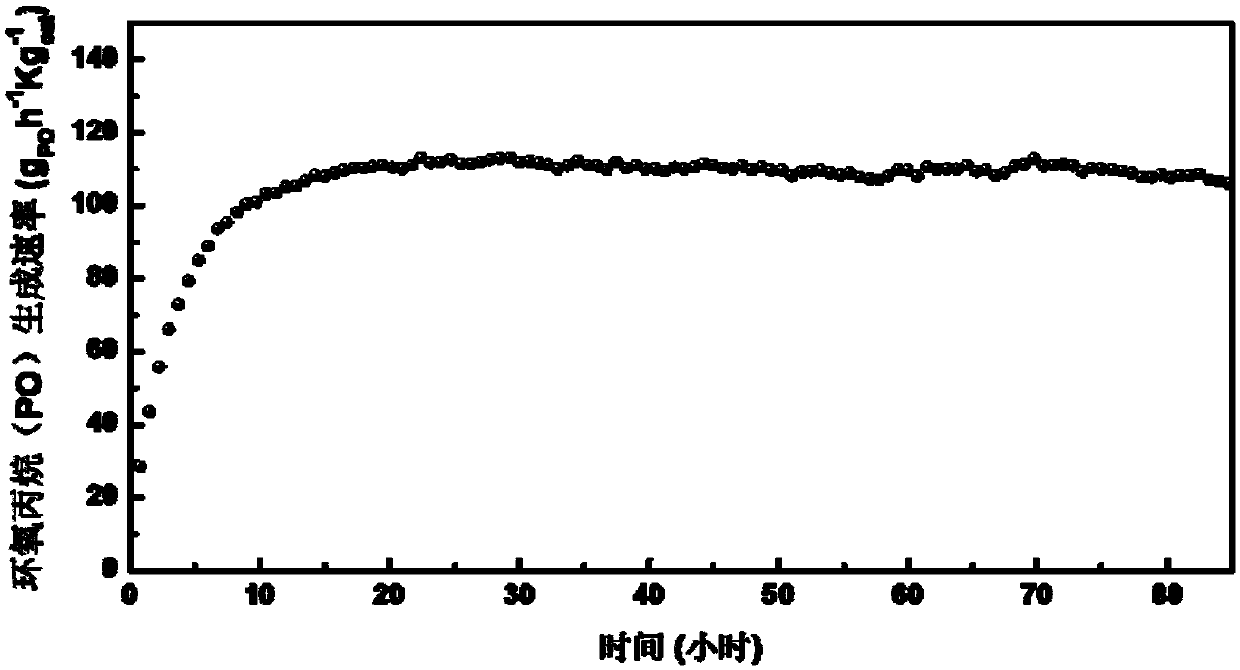

Embodiment 1

[0060] Preparation of Gold Catalyst Using Triphenylphosphine Gold Chloride as Precursor

[0061] Take 1 gram of TS-2 whose micropores have not been blocked by microporous template agent after high-temperature roasting, and place it in a 10mL glass beaker, then weigh 0.20mL of a mixed solution of triphenylphosphine gold chloride and acetone (0.005g / mL), then stirred evenly with a glass rod, stood at room temperature for 12h, then evacuated overnight at room temperature, and then placed the solid in a fixed-bed reactor, from room temperature to 1 degree / min rate to 150 degree, that is, a catalyst with a low loading of 0.04wt%.

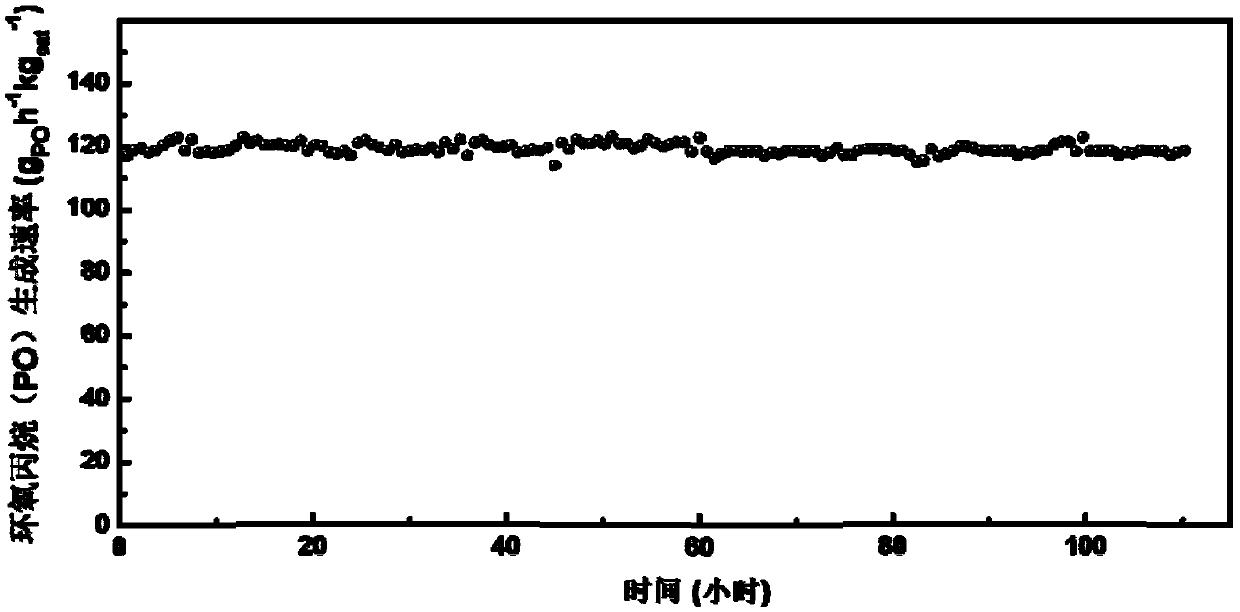

Embodiment 2

[0063] Preparation of Gold Catalyst Using Methyl(triphenylphosphine) Gold(I) as Precursor

[0064] Take 1 gram of TS-2 whose micropores have not been blocked by microporous template agent after high-temperature roasting, and place it in a 10mL glass beaker, and then weigh 0.20mL of methyl (triphenylphosphine) gold (I) and acetone with a pipette. Mix the solution (0.005g / mL), then stir it evenly with a glass rod, let it stand at room temperature for 12h, then evacuate it at room temperature overnight, then place the solid in a fixed bed reactor in a gas composition of oxygen / nitrogen The temperature was raised from room temperature to 280 degrees at a rate of 1 degree / minute, and a catalyst with a low loading of 0.04 wt % was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com