A kind of ultrafine solid electrolyte and preparation method thereof

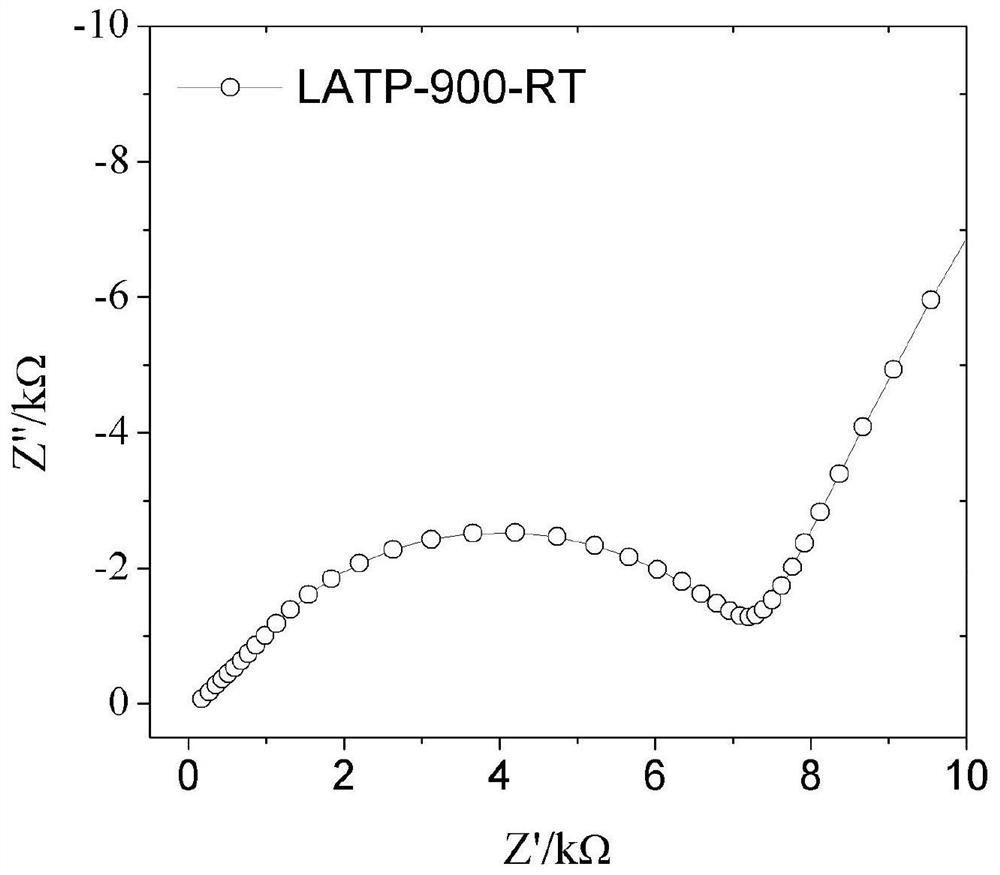

A technology of solid electrolyte and particle size, applied in solid electrolyte, non-aqueous electrolyte, circuit, etc., can solve the problems of high phase formation temperature, long time consumption, large resistance, etc., achieve good processing and coating performance, and simple preparation process , the effect of reducing interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059]This embodiment provides a kind of preparation ultrafine solid state electrolyte, and its specific method is:

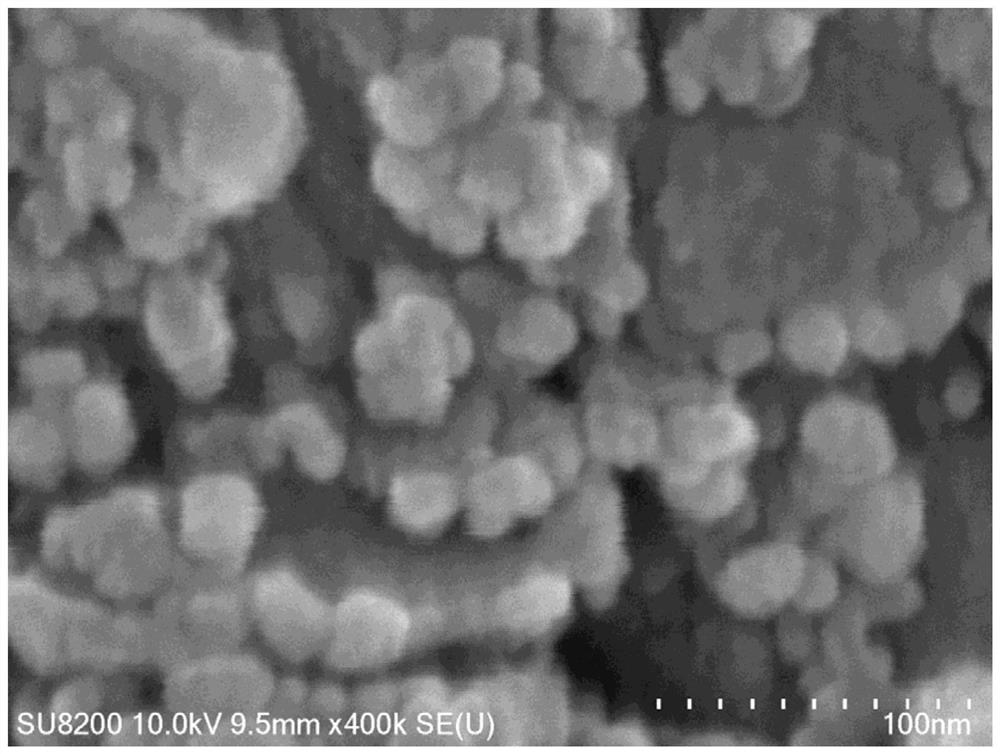

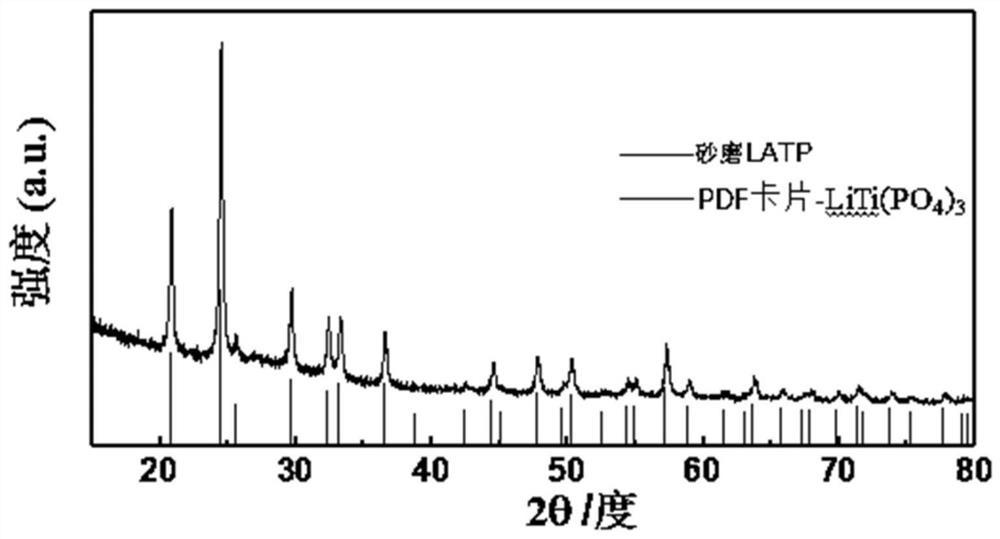

[0060] (1) According to the ion ratio Li:Al:Ti:P is 1.4:0.4:1.6:3, weigh a certain amount of lithium carbonate, aluminum oxide, titanium dioxide and ammonium dihydrogen phosphate, and then add these reactant raw materials into a 1mm zirconium ball Then add pure water, adjust the solid content to 40%, first at a stirring speed of 15Hz, stir for 2h, then add a thickener (polyvinylpyrrolidone) with a mass fraction of 5%, and then stir at a stirring speed of 5%. Stirring for 2 hours at 15 Hz, and then stirring for 6 hours at a stirring speed of 60 Hz, to obtain a spray precursor slurry with a particle size of less than 1 μm;

[0061] (2) Use a two-fluid spray dryer to spray-dry the spray precursor slurry, the inlet temperature is 260°C, and the outlet temperature is controlled at 85°C to obtain a sintered precursor with a spherical microscopic morphology;

[0062]...

Embodiment 2

[0068] This embodiment provides a kind of preparation ultrafine solid state electrolyte, and its specific method is:

[0069] (1) According to the ion ratio Li:Al:Ti:P is 1.3:0.3:1.7:3, weigh a certain amount of lithium hydroxide, aluminum nitrate, titanium dioxide and ammonium dihydrogen phosphate, and then add these reactant raw materials into Ball wet mill, then add pure water, adjust the solid content to 50%, first stir at a speed of 18Hz for 1.5h, and then add a thickener (carboxymethyl cellulose) with a mass fraction of 8% , keep the rotation speed unchanged and continue to stir for 3 hours, then increase the rotation speed to 50Hz, after stirring for 8 hours, a spray precursor slurry with a particle size of less than 1 μm is obtained;

[0070] (2) Use a centrifugal spray dryer to spray-dry the spray precursor slurry. The inlet temperature is 280°C, and the outlet temperature is controlled at 110°C. After spraying, a sintered precursor with a spherical microscopic shape ...

Embodiment 3

[0073] This embodiment provides a kind of preparation ultrafine solid state electrolyte, and its specific method is:

[0074] (1) Take a certain amount of lithium hydroxide, aluminum nitrate, germanium dioxide and ammonium dihydrogen phosphate according to the ion ratio Li: Al: Ge: P is 1.3:0.3:1.7:3, and then add these reactant raw materials into the containing Wet mill with 1mm zirconium balls, then add pure water, adjust the solid content to 40%, stir at a low speed for 2h at a stirring speed of 15Hz, and then add a thickener (polyethylene glycol) with a mass fraction of 10%. ), and then stirred for 3h, and then increased the rotating speed to 45Hz, and after 10h, a particle size of less than 1 μm spray precursor slurry was obtained;

[0075] (2) Use a four-fluid spray dryer to spray-dry the spray precursor slurry. The inlet temperature is 260°C, and the outlet temperature is controlled at 110°C. After spraying, a sintered precursor with a spherical microscopic shape is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com