PVC (polyvinyl chloride) electric power sheath tube and preparation method thereof

A technology for sheathing tubes and electric power, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., to reduce processing costs, improve corrosion resistance, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A PVC power sheath pipe, comprising the following raw materials in parts by weight: vinyl resin 26kg, polyvinyl chloride 88kg, light calcium 10kg, silicon rubber 14kg, paraffin 0.6kg, plasticizer 3kg, stabilizer 0.5kg, Oxidant 0.5kg, flame retardant 2kg;

[0039] The outer surface of the PVC power sheath pipe is sprayed with a layer of corrosion-resistant paint layer, and the corrosion-resistant paint layer is made of the following raw materials in parts by weight: 20kg of epoxy resin, 10kg of polytetrafluoroethylene, 10kg of quartz powder, viscose Binder 3kg, compatibilizer 1kg, carbon fiber 5kg, acetone 3kg.

[0040] The preparation method of the PVC power sheathed pipe comprises the following steps:

[0041] (1) Pulverize the massive raw material in the raw material into powder, and set aside;

[0042] (2) mixing and stirring the powder obtained in step (1) and the remaining raw materials at high temperature to obtain a mixture;

[0043] (3) adding the compound in...

Embodiment 2

[0052] A PVC power sheath pipe, comprising the following raw materials in parts by weight: 20kg of vinyl resin, 80kg of polyvinyl chloride, 10kg of light calcium, 10kg of silicone rubber, 0.5kg of paraffin wax, 2kg of plasticizer DBP, and 0.5kg of rare earth stabilizer , antioxidant TPP0.5kg, melamine and polyphosphate mixed flame retardant 1kg;

[0053] The outer surface of the PVC power sheath pipe is sprayed with a layer of corrosion-resistant paint layer, and the corrosion-resistant paint layer is made of the following raw materials in parts by weight: 23kg of epoxy resin, 12kg of polytetrafluoroethylene, 12kg of quartz powder, viscose Binder 3kg, compatibilizer 2kg, carbon fiber 6kg, acetone 5kg.

[0054] The preparation method of the PVC power sheathed pipe comprises the following steps:

[0055] (1) pulverizing the massive raw material in the raw material into a powder with a fineness of 80 meshes for subsequent use;

[0056] (2) Stir the powder obtained in step (1) a...

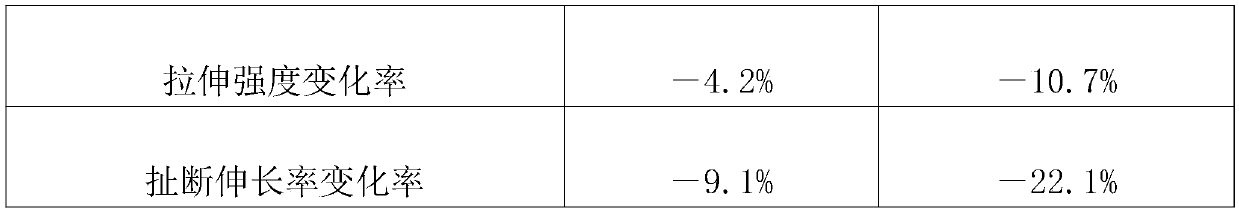

Embodiment 3

[0066] A PVC power sheath pipe, comprising the following raw materials in parts by weight: vinyl resin 25kg, polyvinyl chloride 85kg, light calcium 11kg, silicone rubber 12kg, paraffin 0.8kg, plasticizer DEP 2.5kg, lead salt stabilizer 0.6kg portion, antioxidant TNP 0.8kg, flame retardant 3kg;

[0067] The outer surface of the PVC power sheath pipe is sprayed with a layer of corrosion-resistant paint layer, and the corrosion-resistant paint layer is made of the following raw materials in parts by weight: 25kg of epoxy resin, 13kg of polytetrafluoroethylene, 15kg of quartz powder, viscose Binder 4kg, compatibilizer 3kg, carbon fiber 8kg, acetone 7kg.

[0068] The preparation method of the PVC power sheathed pipe comprises the following steps:

[0069] (1) pulverizing the massive raw material in the raw material into a powder with a fineness of 85 meshes for subsequent use;

[0070] (2) Stir the powder obtained in step (1) and the rest of the raw materials at a stirring temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of change of tensile strength | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

| rate of change of tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com