Bismaleimide resin composition and solidified matter thereof as well as composite material

A dual-horse resin and composite material technology, used in the field of thermosetting resins, can solve the problems of low interfacial bonding strength, high interlayer strength, low reactivity, etc., and achieve excellent mechanical performance stability, high tensile strength, and bonding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The raw material used in embodiment and comparative example is as follows:

[0032] 【Phosphorus-containing double horse resin】

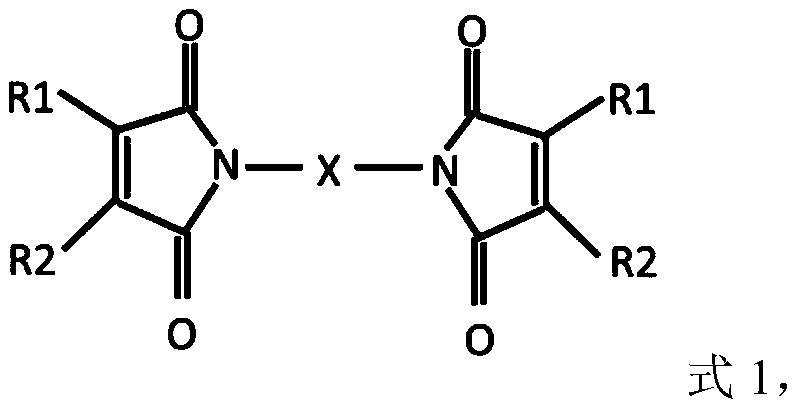

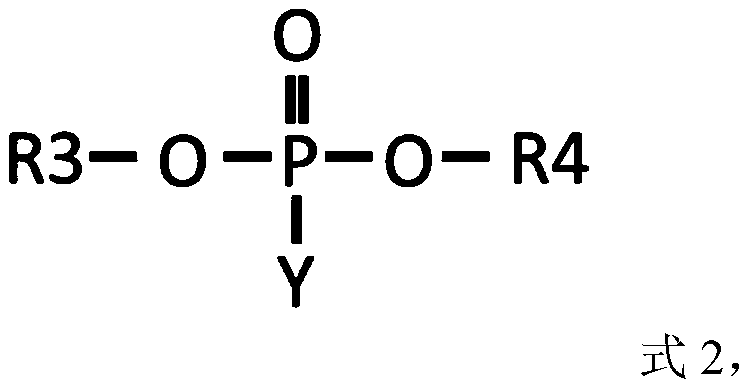

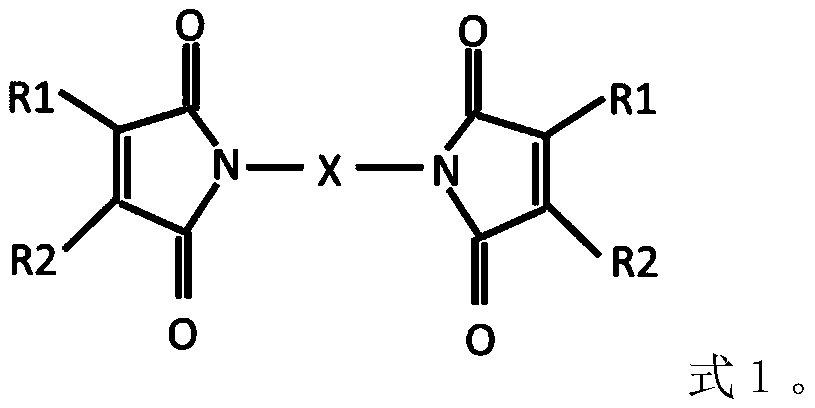

[0033] A1: has the structure shown in formula 1, wherein X in formula 1 is the structure shown in formula 3, R1 and R2 are hydrogen, R5 and R6 are -CH 2 (CH 2 ) 6 CH 2 —, R7 is —CH 2 (CH 2 ) 6 CH 3 .

[0034] A1 was synthesized as follows:

[0035] Under nitrogen atmosphere, mix 0.1mol tri-n-octylphosphine oxide and 200ml 96% sulfuric acid, cool to -5°C, prepare 14.5g fuming nitric acid / 100ml sulfuric acid solution, add dropwise to the above mixed solution, after 2h, heat up To 25 ℃ reaction 8h. 2L of ice was added, and after the ice melted, it was extracted with chloroform and washed with aqueous sodium bicarbonate until neutral. Remove the solvent, and after recrystallization, react with 180g of stannous chloride, 200ml of fuming nitric acid, and 400ml of ethanol at room temperature for 5h. It was neutralized with NaOH aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com