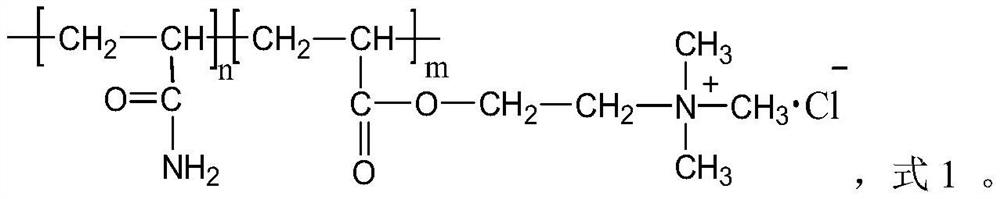

Preparation method of series cationic degree and high intrinsic viscosity p(dac-am)

A cationic degree and characteristic viscosity technology, which is applied in the field of preparation of cationic polyacrylamide copolymers, can solve problems such as continuous decline in monomer content, limited characteristic viscosity of polymerization products, incomplete cationic degree coverage, etc., to prevent characteristic viscosity. Loss, improved monomer conversion, and easy drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step, in the polymerization reactor that has thermometer, stirrer, condensing recovery steam and nitrogen device, add the mixed solution that mass ratio is the methanol and ethanol of 80:20, get the content of alcohol (in mass fraction, below The same) is (5.00±0.01)% alcohol aqueous solution, then add industrial monomers DAC and AM with a substance ratio of 1:9, add alcohol water to adjust the monomer content of the system to 20%, and stir evenly under nitrogen atmosphere ;

[0031] In the second step, in the above-mentioned reaction kettle, the metal complexing agent tetrasodium ethylenediamine tetraacetate of 0.035% by mass ratio of the monomers is added, and the molar ratio of ammonium persulfate and sodium bisulfite is 2:1, accounting for The monomer mass ratio is 0.57%;

[0032] In the third step, nitrogen gas is introduced, and after stirring for 20 minutes, the reaction liquid is heated to (32.0±1.0)°C, and the heat preservation polymerization is carr...

Embodiment 2

[0036] In the first step, a mixture of methanol and ethanol with a mass ratio of 40:60 is added to a polymerization reactor equipped with a thermometer, a stirrer, steam condensation recovery and a nitrogen device to obtain an alcohol content of (3.00 ± 0.01)% Alcohol aqueous solution, then add industrial monomers DAC and AM with a substance ratio of 3:7, add alcohol water to adjust the monomer content of the system to 37%, and stir evenly under a nitrogen atmosphere;

[0037] In the second step, in the above-mentioned reaction kettle, the metal complexing agent tetrasodium ethylenediamine tetraacetate of 0.030% by mass ratio of the monomers is added, and the molar ratio of ammonium persulfate and sodium bisulfite is 2:1, accounting for The monomer mass ratio is 0.36%;

[0038] In the third step, nitrogen gas is introduced, and after stirring for 20 minutes, the reaction solution is heated to (35.0±1.0)°C, and the temperature is maintained for (3.0±0.5) hours;

[0039] The fo...

Embodiment 3

[0042] In the first step, a mixed solution of methanol and ethanol with a mass ratio of 20:80 is added to a polymerization reactor with a thermometer, a stirrer, steam condensation recovery and a nitrogen device to obtain an alcohol content of (1.00 ± 0.01)%. Alcohol aqueous solution, then add industrial monomers DAC and AM with a substance ratio of 5:5, add alcohol water to adjust the monomer content of the system to 40%, and stir evenly under a nitrogen atmosphere;

[0043] In the second step, in the above-mentioned reaction kettle, the metal complexing agent tetrasodium ethylenediamine tetraacetate of 0.025% by mass ratio of the monomers is added, and the molar ratio of ammonium persulfate and sodium bisulfite is 1:1, accounting for The monomer mass ratio is 0.27%;

[0044] In the third step, nitrogen gas is introduced, and after stirring for 20 minutes, the reaction solution is heated to (38.0±1.0)°C, and the polymerization is carried out for (3.0±0.5) hours;

[0045] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com