Graphene-surface-grafted free radical polymer composite material, and preparation method and use thereof

A graphene surface, composite material technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of limited performance improvement of secondary batteries, unsuitable for mass production, difficult to control graft content, etc. The preparation method is simple and easy, excellent dispersibility, and high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Synthesis of graphene oxide grafted poly(2,2,6,6-tetramethylpiperidine-4-methacrylate) (GO-g-PTMPM) composite:

[0069] Add 100mg of graphene oxide and 50mL of N-methylpyrrolidone into a 100mL reaction bottle, add 2.25g of TMPM after ultrasonic dispersion, and after bubbling with nitrogen for 30min, add 32.8mg of azobisisobutyronitrile and react at 65°C 48 hours. After the reaction was finished, GO-g-PTMPM with a graft content of 45.4% was obtained by suction filtration, washing and drying.

[0070] FT-IR (cm -1 ):3400(νO-H), 2960(νC-H), 2930(νC-H), 1725(νC=O).

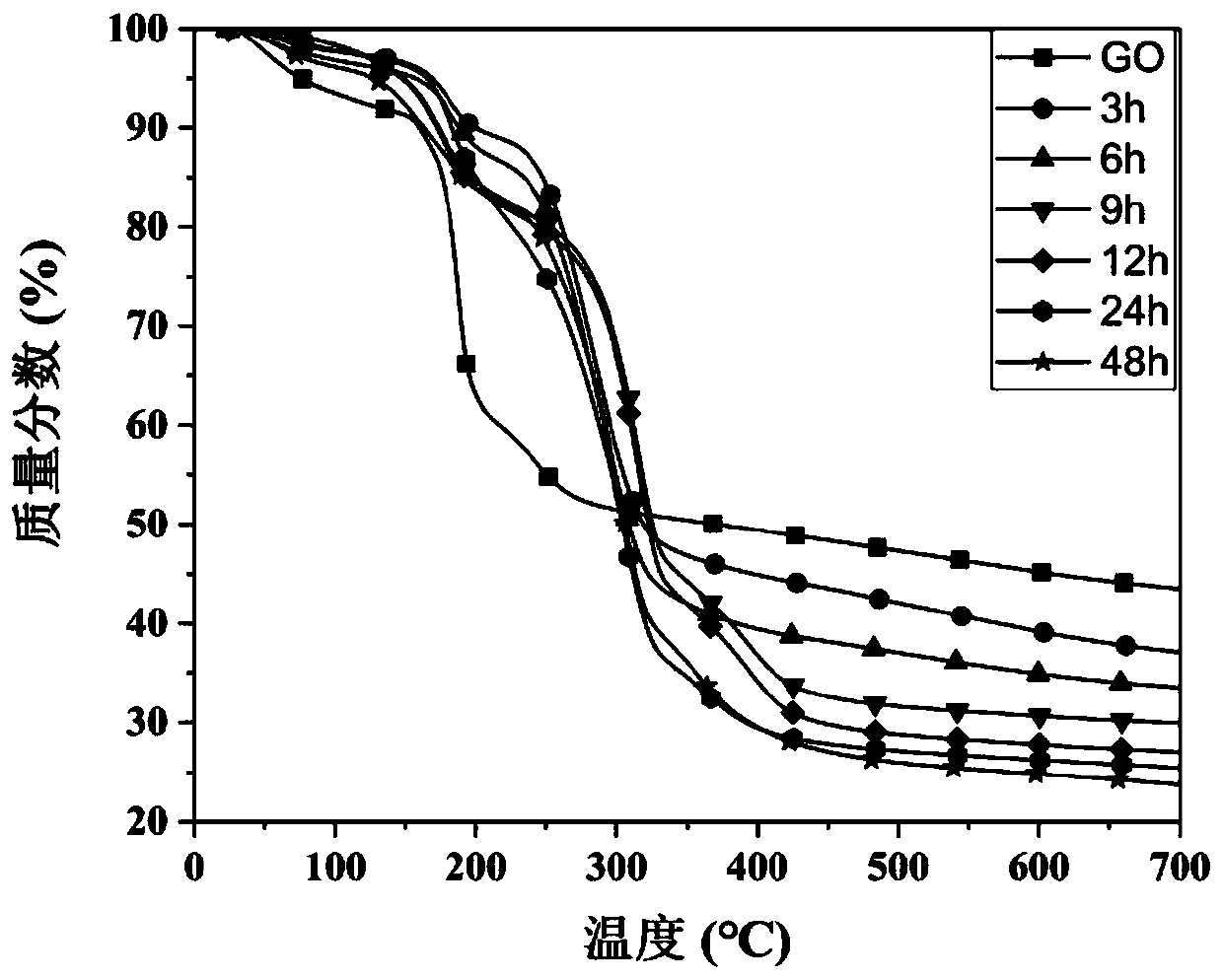

[0071] This example further proves that the graft content of PTMPM grafted on the surface of the graphene oxide sheet can be adjusted by controlling the time of the polymerization reaction.

[0072] attached figure 2 The thermogravimetric curves of GO-g-PTMPM composites obtained by polymerization at 65°C for 3-48h respectively, it can be seen from the figure that as the polymerization reaction t...

Embodiment 2

[0077] Example 2: Synthesis of graphene oxide grafted poly(2,2,6,6-tetramethylpiperidine-4-methacrylate) (GO-g-PTMPM) composite:

[0078] In the reaction bottle of 100mL, add 100mg graphene oxide and 50mL N-methylpyrrolidone, add 2.25g TMPM (molecular weight is 225) after ultrasonic dispersion, pass into nitrogen bubble after 30min, add 16.4mg azobisisobutyronitrile ( The molecular weight is 164), reacted at 65°C for 48 hours. After the reaction was finished, GO-g-PTMPM with a graft content of 30.2% was obtained by suction filtration, washing and drying.

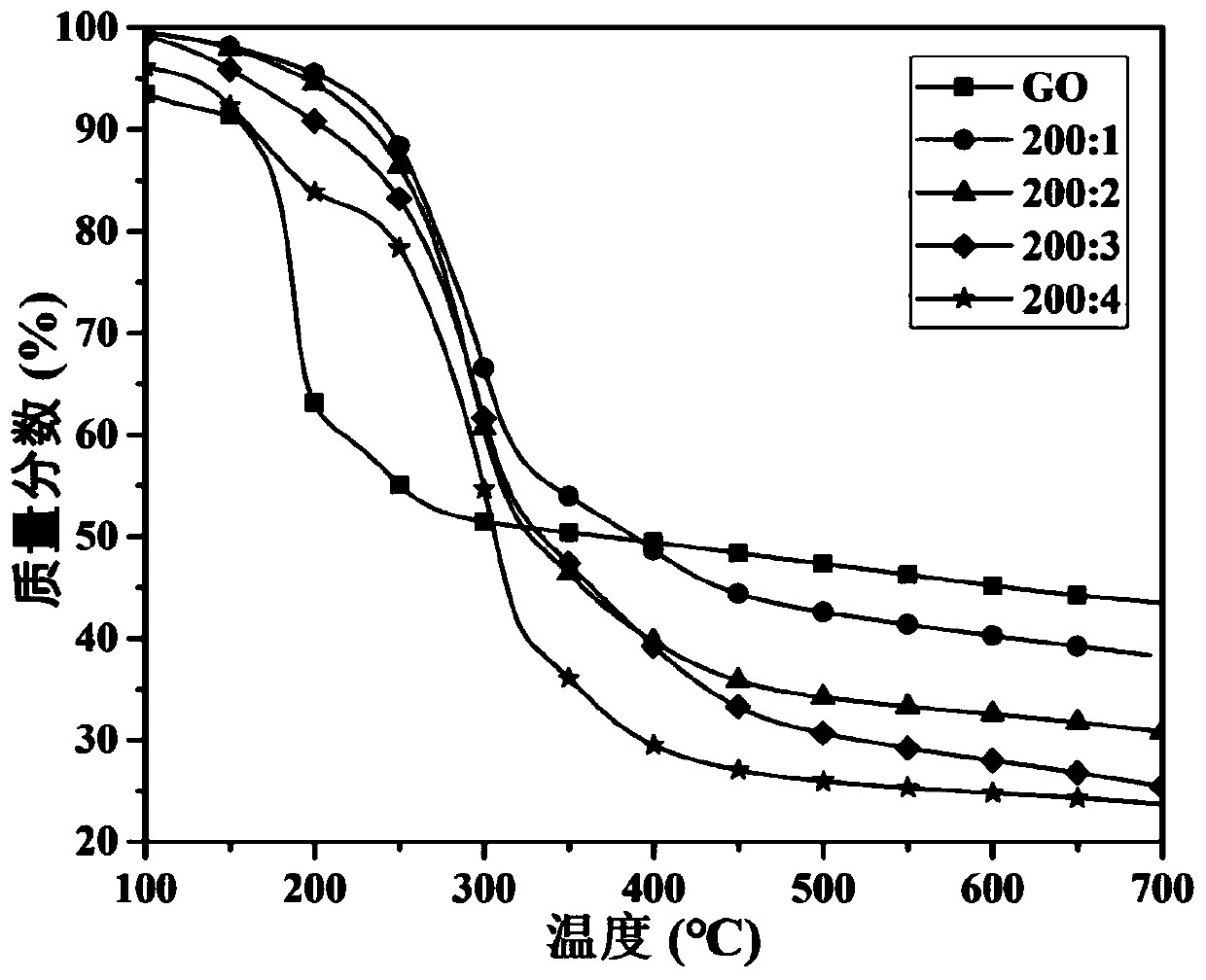

[0079]This example further proves that the graft content of PTMPM grafted on the surface of the graphene oxide sheet can be adjusted by controlling the amount of the initiator.

[0080] Table 2 The graft content of GO-g-PTMPM composites obtained with different initiator dosages

[0081] Monomer to Initiator Molar Ratio

[0082] attached image 3 It is the thermogravimetric curve of the GO-g-PTMPM composite mater...

Embodiment 3

[0083] Example 3: Synthesis of graphene oxide grafted poly(2,2,6,6-tetramethylpiperidine-1-oxyl radical-4-methacrylate) (GO-g-PTMA):

[0084] In the reaction bottle of 250mL, add 100mg GO-g-PTMPM (being specifically the GO-g-PTMPM that graft content is 45.4% among the embodiment 1) and 100mL methyl alcohol, add 30mg disodium edetate and 20mg of sodium tungstate dihydrate, then slowly add 4mL of 30% hydrogen peroxide (density about 1.1). After stirring and reacting for 48h, GO-g-PTMA was obtained by suction filtration, washing and drying.

[0085] FT-IR (cm -1 ):3400(νO-H), 2960(νC-H), 2930(νC-H), 1725(νC=O), 1363(νN-O).

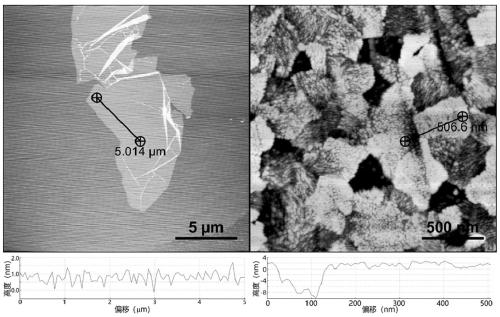

[0086] attached figure 1 The AFM and height distribution diagram of GO on the left, and the AFM and height distribution diagram of GO-g-PTMA on the right, it can be seen that the average thickness of GO sheets is 1.0nm, while the average thickness of GO-g-PTMA is 9nm.

[0087] attached Figure 6 For the electron paramagnetic resonance (ESR) curve of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com