Lithium ion all-solid all-battery and preparation method thereof

An all-solid-state, all-battery technology, used in lithium batteries, battery electrodes, secondary batteries, etc., can solve the problems of low lithium ion conductivity, loss of active materials, and decreased electrochemical cycle stability of silicon anodes, to avoid safety. The effect of avoiding hidden dangers, inhibiting volume expansion, and avoiding the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]A method for preparing a lithium sulfide / silicon solid-state full battery, comprising the steps of:

[0044] (1) Preparation of silicon / solid electrolyte composite anode material refers to the patent "A silicon anode material coated with sulfur-based solid electrolyte and its preparation method" to prepare the corresponding anode material";

[0045] (2) The lithium sulfide / carbon composite was prepared by ball milling or absolute ethanol dissolution.

[0046] (3) Sulfur-based solid electrolyte prepared by solution method or ball milling sintering method.

[0047] (4) Silicon / sulfur-based solid electrolyte composite anode material, sulfur-based solid electrolyte and carbon material are ball milled or ground with a mortar under certain conditions.

[0048] (5) Lithium sulfide / carbon composite material, sulfur-based solid electrolyte and carbon material are ball milled or ground with a mortar under certain conditions.

[0049] (6) Assemble the negative electrode obtained ...

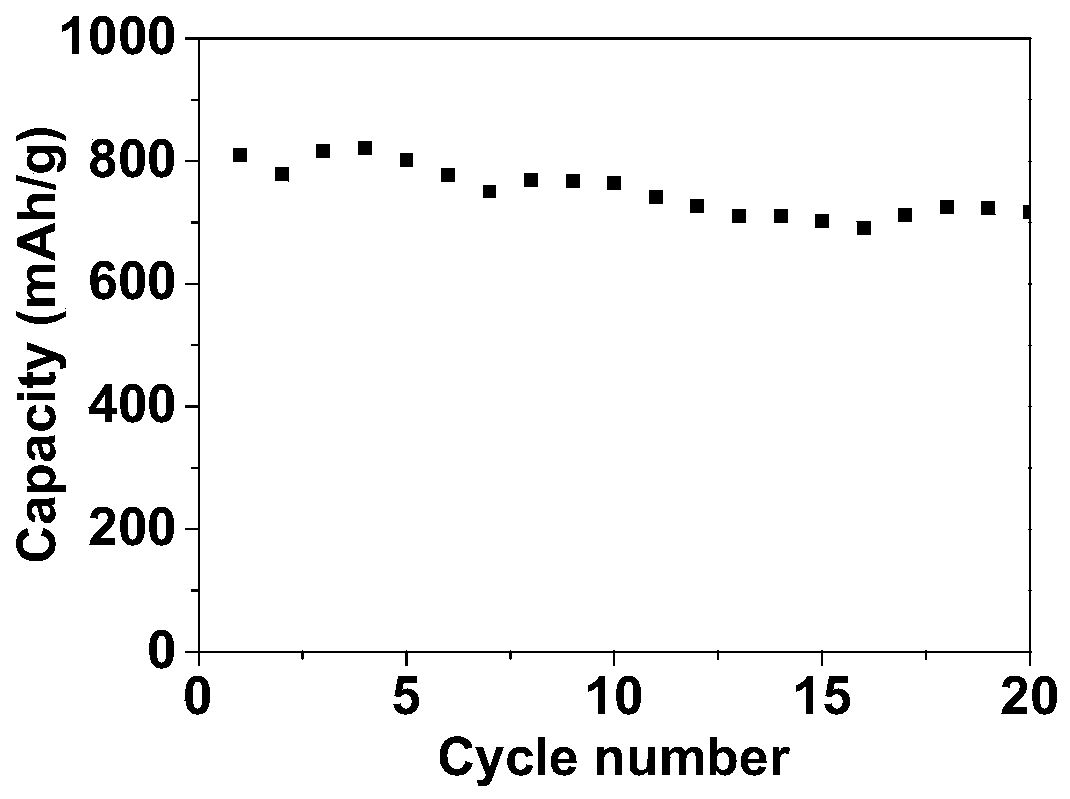

Embodiment 1

[0063] Grind lithium sulfide and phosphorus pentasulfide in a mortar at a ratio of 1:1 (molar ratio), add silicon and ground sulfide to tetrahydrofuran at a ratio of 1:1 (mass ratio), stir magnetically at room temperature for 8 hours, and use rotary evaporation The organic solvent was removed by the method, and the heat treatment was performed at 50° C. for 24 hours to obtain a silicon / sulfur-based solid electrolyte composite negative electrode material.

[0064] Lithium sulfide and Ketjen black were mixed and ball-milled at a ratio of 3:1 (mass ratio) for 24 hours to obtain a lithium sulfide / carbon composite material. Preparation of solid electrolyte Li by solution method using lithium sulfide and phosphorus pentasulfide as raw materials 4 P 2 S 6 .

[0065] Preparation of solid electrolyte Li by solution method using lithium sulfide and phosphorus pentasulfide as raw materials 7 P 3 S 11 .

[0066] The silicon / sulfur-based solid electrolyte composite anode material, t...

Embodiment 2

[0068] Mill lithium sulfide, phosphorus pentasulfide, and aluminum sulfide in a ball mill for 12 hours at a ratio of 5:2:1 (molar ratio), and add silicon and mixed sulfide to dimethyl ether at a ratio of 1:5 (mass ratio), at 50°C Under magnetic stirring for 24 hours, the organic solvent was removed by suction filtration, and heat treated at 700° C. for 6 hours to obtain a silicon / sulfur-based solid electrolyte composite negative electrode material.

[0069] Dissolve lithium sulfide in absolute ethanol to obtain a solution with a mass fraction of 10%, add a certain amount of graphite solution, wherein the mass ratio of graphene to lithium sulfide is 1:1, evaporate the ethanol to dryness, and obtain the powder under argon atmosphere Heat treatment at 500°C for 8 hours to obtain a lithium sulfide / carbon composite material.

[0070] The silicon / sulfur-based solid-state electrolyte composite negative electrode material, the sulfur-based solid-state electrolyte, and the carbon mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com