Cyclocarbonate epoxy compound, cationic polymerizable composition and application thereof

A cationic polymerization, epoxy compound technology, applied in the application, epoxy resin coating, polyurea/polyurethane adhesive, etc., to achieve excellent retention and mechanical properties, excellent performance, and improve the effect of polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

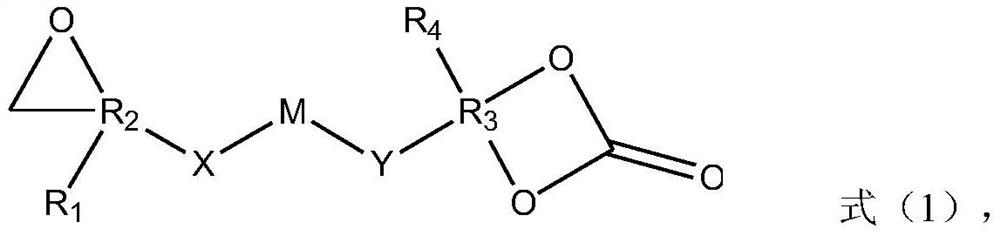

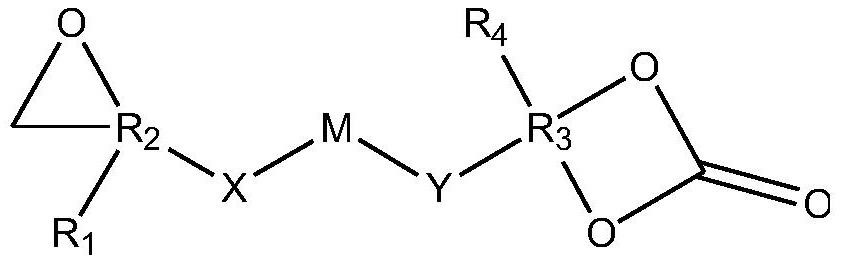

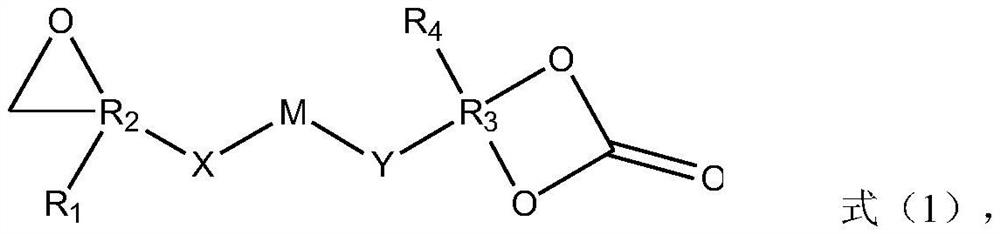

[0038]In a preferred embodiment, the cyclic carbonate epoxy compound is prepared by the preparation method, the preparation method comprising: a hydrolysis reaction: a hydrolysis reaction in the compound A under the action of the first catalyst, to obtain a hydrolyzate, Compound A The structure is as shown in the formula (2):

[0039]and

[0040]Ring reaction: Under the action of the second catalyst, the hydrolyzate is carried out to ring to the compound B, resulting in a cyclic carbonate epoxy compound, and the compound B structure is shown in formula (3):

[0041]

[0042]Further, both the first catalyst and the second catalyst are alkaline catalysts; preferably, the first catalyst and the second catalyst are independently selected from one or more of sodium hydroxide, potassium hydroxide, and aluminum hydroxide, respectively.

[0043]In a preferred embodiment, in the hydrolysis reaction, the amount of the first catalyst is from 0.5 to 5 wt%, preferably 0.7 to 1.5% by weight, based on the cyclic...

Embodiment 1

[0059]Example 1 :

[0060](1) Preparation of the coating liquid: The polyacrylate P-1 is added to the cyclic carbonate epoxide 1 and cyclic carbonate epoxy compounds 2, F-1 and F-2, respectively, of the formula (1). The dissolution was stirred at 60 ° C, then the cationic initiator and polydimethylsiloxane were added under a dark environment, and the soluble material was filtered with a polytetrafluoroethylene filter having a pore diameter of 0.45 μm, resulting in a liquid crystal material. Solution.

[0061]Table 1

[0062]

[0063]Note: Table 1 is shown in Table 2 in Table 2 in Table 2 in the name / composition of the components represented by the code.

[0064]Table 2

[0065]

[0066]Among them, the structure of the acrylic compound 1 is as follows:

[0067]

[0068]The structure of the acrylic compound 2 is as follows:

[0069]

[0070]The structure of F-1 is as follows:

[0071]

[0072]The structure of F-2 is as follows:

[0073]

[0074](2) The polyimide film having a thickness of 50 μm was frictionally treated with a ...

Embodiment 2

[0086]Example 2 :

[0087]The bisphenol A dihydrate glycene ether, the compound 3, and the diphenyl hexafluorophosphate phosphate salt are added to the stirred tank according to the ratio of Table 4, and the mixture is stirred at a normal temperature to mix well, then add titanium white powder to stir for 4 h, then add Hydroxybenzyl ether, polydimethylsiloxane and nano silica, stirred for 2 h, mix well after filtration, and prepared the desired photocurable coating.

[0088]Table 4

[0089]

[0090]The photocurable coating produced by the above scheme 1 and Comparative Example 1 was uniformly coated on the surface of the metal matrix (cold rolled steel plate, the galvanized plate or silicon steel sheet), and then placed in the DYMAX fixed curing device. , Curing 60S with medium pressure mercury lamp (3.3J / cm2UVA), the performance test is performed after light curing, and the test results are shown in Table 5.

[0091]table 5

[0092] sample Attachment Pencil hardness Impact resistance VOC (%) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com