Tin dioxide/zinc oxide composite nanowire material and preparation method thereof

A technology of zinc oxide nanowires and tin dioxide, applied in nanotechnology, semiconductor/solid-state device manufacturing, organic semiconductor devices, etc., can solve the problem of increased electron and hole recombination probability, increased electron transmission path, and reduced solar cell efficiency etc. to achieve the effects of increasing light absorption, reducing transmission paths, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The tin dioxide / zinc oxide composite nanowire material in this embodiment includes a tin dioxide nanowire array substrate and a zinc oxide nanowire array grown on the substrate. Wherein, the length of the tin dioxide nanowire is 300nm and the diameter is 50nm, and the length of the zinc oxide nanowire is 500nm.

[0025] The preparation method of the composite nanowire material comprises the following steps:

[0026] (1) Preparation of anodized aluminum nanoporous template: wash the 1.5×1.5 cm FTO conductive substrate with toluene, acetone, ethanol and deionized water respectively. Using thermal evaporation method to A thermal evaporation rate of 300 nm of aluminum was deposited on the FTO conductive substrate, and the sample holder was rotated during the deposition to ensure uniform film thickness. Then use a copper strip to contact the surface of the aluminum, seal the substrate in the electrolytic cell, use the method of anodic oxidation, use a platinum mesh electr...

Embodiment 2

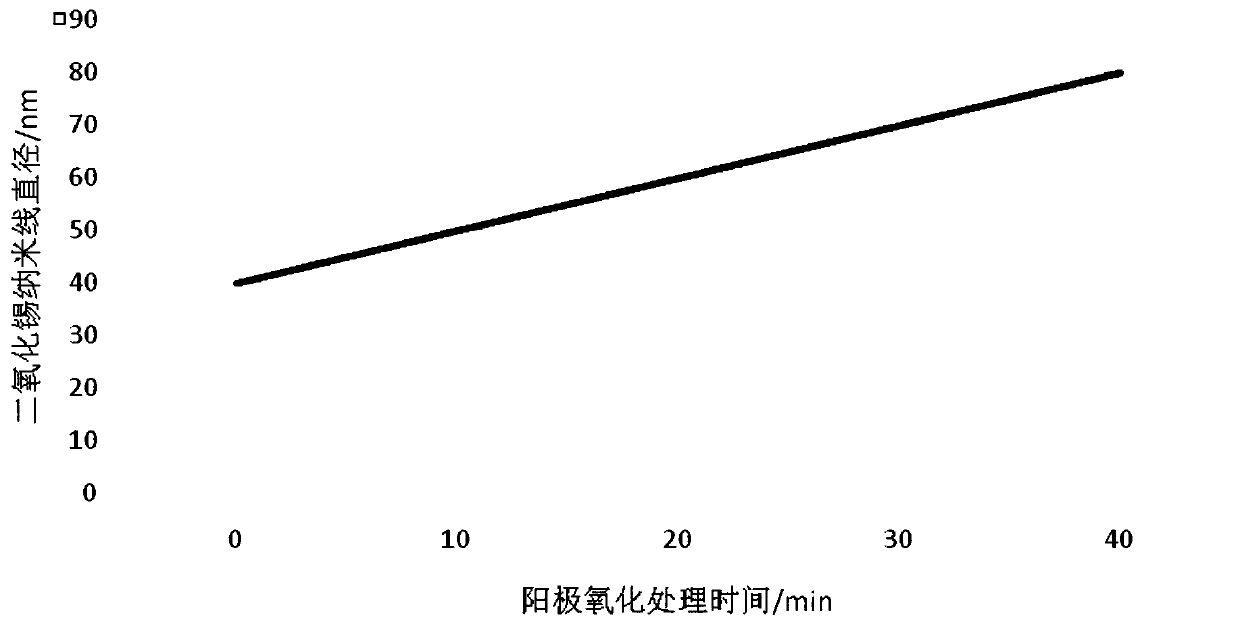

[0034] Design 5 groups of comparative tests, test procedure is basically the same as embodiment 1, difference is the anodic oxidation time in step (1), concrete time is shown in Table 1, then the tin dioxide nanowire material diameter of preparation is compared, The results obtained are shown in Table 1 below.

[0035] Tin dioxide nanowire diameter comparison table prepared by different anodizing time in table 1

[0036]

[0037] It can be seen from Table 1 that with the increase of anodization time, the diameter of tin dioxide nanowires gradually increases. If the tin dioxide nanowire diameter is too large, it is not conducive to perovskite penetration in the tin dioxide nanowire, if the diameter of the tin dioxide nanowire is too small, when the zinc oxide nanowire seed layer is spin-coated, the seed layer solution will penetrate Into the gap of the nanowires, so that the zinc oxide nanowires cannot grow on the tin dioxide nanowires, so we choose the anodizing time as 10...

Embodiment 3

[0039] The tin dioxide / zinc oxide composite nanowire material of the present invention comprises a tin dioxide nanowire array substrate and a zinc oxide nanowire array grown on the substrate. Wherein, the length of the tin dioxide nanowire is 400nm and the diameter is 60nm, and the length of the zinc oxide nanowire is 500nm.

[0040] The preparation method of the composite nanowire material comprises the following steps:

[0041] (1) Preparation of anodized aluminum nanoporous template: wash the 1.5×1.5 cm FTO conductive substrate with toluene, acetone, ethanol and deionized water respectively. Using thermal evaporation method to A thermal evaporation rate of 400 nm of aluminum was deposited on the FTO conductive substrate, and the sample holder was rotated during the deposition to ensure uniform film thickness. Then use a copper strip to contact the surface of the aluminum, seal the substrate in the electrolytic cell, and use an anodic oxidation method to use a platinum me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com