Bed layer material for melting waste incineration fly ash, preparation technology and treatment method

A technology for waste incineration fly ash and preparation process, which is applied in the field of environmental engineering, can solve the problems of high difficulty and cost of secondary pollution operation, high equipment cost, high process energy consumption, etc., and achieves easy large-scale industrial production and application. The effect of low curing rate and melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

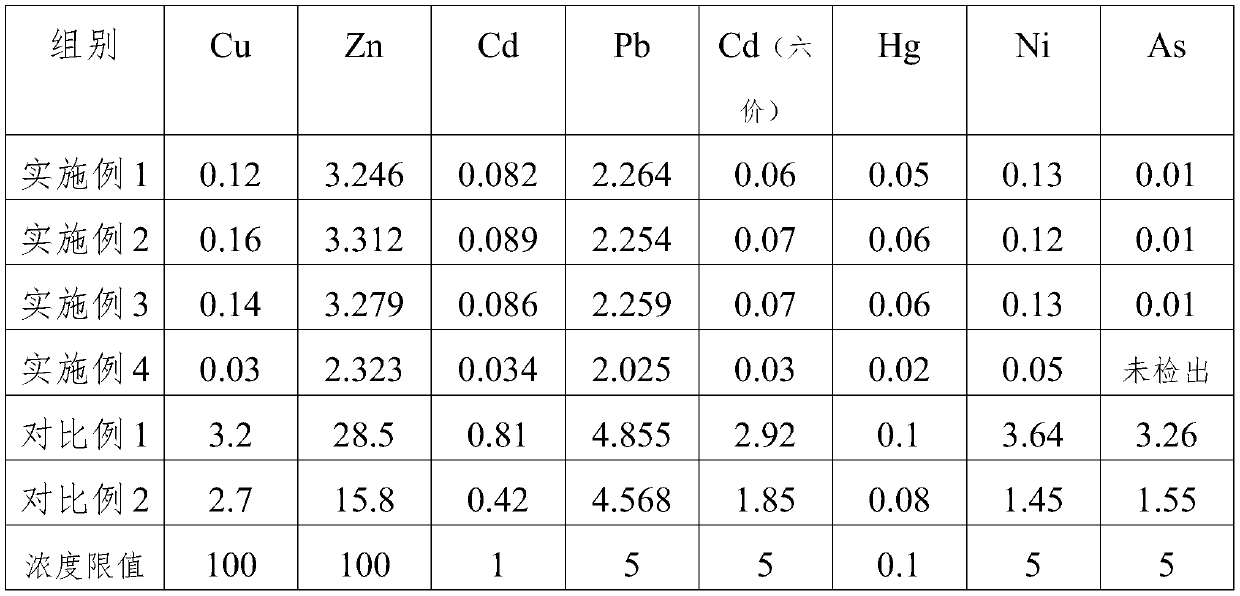

Examples

Embodiment 1

[0036] The fly ash in this example was taken from the SDA desulfurization tower and bag filter of a waste incineration plant in Beijing, and was analyzed by X-ray fluorescence spectrometer. The basic components are shown in Table 1.

[0037] Table 1 Basic composition (mass fraction) of fly ash %

[0038] CaO SiO 2

Cl S al 2 o 3

C H MgO Fe 2 o 3

36.80 8.42 24.69 3.62 3.01 3.24 0.33 2.33 1.07

[0039] The flux consists of TiO with a weight ratio of 0.2:0.3:0.1:0.2 2 , MgO, B 2 o 3 , CaF 2 Mix made.

[0040] The preparation process of the bed material for the melting of waste incineration fly ash in this embodiment comprises the following steps:

[0041] (1) Raw material pretreatment

[0042] The fly ash and flux are crushed separately, and the particle size of each component after crushing is 100-120 mesh;

[0043] (2) Raw material ratio

[0044] Mix the crushed fly ash, silica sand, quicklime, flux, bentonite, coal po...

Embodiment 2

[0048] The composition of the fly ash in this example is the same as that in Example 1.

[0049] The flux consists of TiO with a weight ratio of 0.3:0.1:0.2:0.1 2 , MgO, Borax, CaF 2 Mix made.

[0050] The preparation process of the bed material for the melting of waste incineration fly ash in this embodiment comprises the following steps:

[0051] (1) Raw material pretreatment

[0052] Fly ash, waste glass, soda ash, flux, sodium metasilicate, and charcoal are crushed separately, and the particle size of each component after crushing is 60-80 mesh;

[0053] (2) Raw material ratio

[0054]Mix the crushed fly ash, waste glass, soda ash, flux, sodium metasilicate, charcoal, and leachate according to the weight ratio of 0.74:0.11:0.06:0.04:0.03:0.02:0.07, and stir evenly to make mud ;

[0055] (3) extrusion molding

[0056] The mud is introduced into a granulation molding machine for extrusion molding. The extrusion molding pressure is 1.0 MPa. After cooling and sieving, a...

Embodiment 3

[0058] The fly ash in this example was taken from the SDA desulfurization tower and bag filter of a waste incineration plant in Beijing, and was analyzed by X-ray fluorescence spectrometer. The basic components are shown in Table 2.

[0059] Table 2 Basic composition (mass fraction) of fly ash %

[0060] CaO SiO 2

Cl S al 2 o 3

C H MgO Fe 2 o 3

36.40 8.19 23.16 3.55 2.97 3.26 0.28 2.44 0.97

[0061] The flux consists of TiO with a weight ratio of 0.2:0.2:0.1:0.2 2 , MgO, B 2 o 3 , CaF 2 Mix made.

[0062] The preparation process of the bed material for the melting of waste incineration fly ash in this embodiment comprises the following steps:

[0063] (1) Raw material pretreatment

[0064] Fly ash, silica sand, soda ash, flux, bentonite, and gasification residue are crushed separately, and the particle size of each component after crushing is 120-150 mesh;

[0065] (2) Raw material ratio

[0066] Mix the crushed fly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com