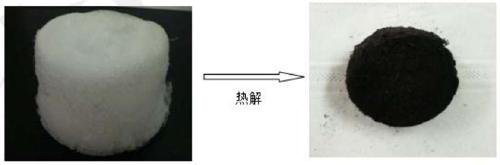

Preparation method of carbon aerogel material with superhigh specific surface area

A technology of ultra-high specific surface area, carbon aerogel, which is applied in aerogel preparation, carbon preparation/purification, chemical instruments and methods, etc. The problem is that the equipment and preparation process are economical and easy to implement, the steps are easy to control, and the preparation process is concise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

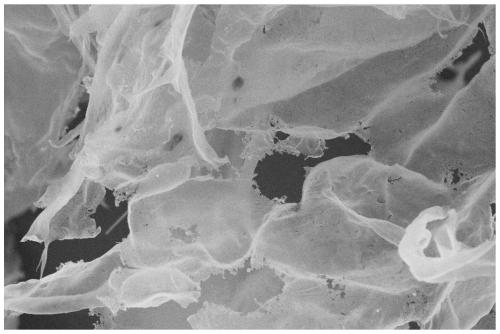

Method used

Image

Examples

Embodiment 1

[0041] Step 1. Biomass fiber such as wet-ground wood pulp

[0042](1) Take 15.0 g of dried wood pulp and other biomass fibers and disperse them in 150 ml of distilled water to prepare a wood pulp and other biomass fiber suspension.

[0043] (2) Pour the above suspension into a 500ml agate ball mill jar, and add 100g agate balls to the agate jar at the same time.

[0044] (3) The agate jar is placed in a planetary ball mill, and ball milled at a speed of 200r / min for 3 hours respectively. After the ball milling, the balls and the suspension are separated for later use.

[0045] Step 2. Biomass fibers such as wood pulp after TEMPO oxidation and ball milling

[0046] (1) Take an appropriate amount of the suspension after ball milling in step 1 and add 100ml of a mixed aqueous solution containing 0.1g of sodium bromide and 0.01g of 2,2,6,6-tetramethylpiperidinium oxide, fully stir and mix, then for the pre-oxidation system.

[0047] (2) Add 100ml of sodium hypochlorite solution...

Embodiment 2

[0055] Step 1. Wet ball milling of newspaper fiber material

[0056] (1) Take 25 g of dried newspaper fiber material and disperse it in 150 ml of distilled water to prepare a newspaper fiber suspension.

[0057] (2) Pour the above suspension into a 500ml agate ball mill jar, and add 150g agate balls to the agate jar simultaneously.

[0058] (3) The agate jar is placed in a planetary ball mill, and ball milled at a speed of 250 r / min for 4 hours. After the ball milling, the ball milling beads and the suspension are separated for later use.

[0059] Step 2. Newspaper fiber after TEMPO oxidation ball milling

[0060] (1) Take an appropriate amount of the suspension after ball milling in step 1 and add 150ml of a mixed aqueous solution containing 0.1g of sodium bromide and 0.01g of 2,2,6,6-tetramethylpiperidinium oxide, fully stir and mix. for the pre-oxidation system.

[0061] (2) Add 150ml of sodium hypochlorite solution with active chlorine content greater than 9% into dilut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com