Iodine-loaded bioactive glass for wound care and application of iodine-loaded bioactive glass

A bioactive glass, wound care technology, applied in the medical and health field to achieve long-lasting antibacterial efficacy, rapid repair and broad-spectrum regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 0.6g chitosan was added to 20ml 2% glacial acetic acid aqueous solution to prepare 3% chitosan aqueous solution, and 40ml ethanol was added. Add 12.5g ethyl orthosilicate and 8.5g calcium nitrate tetrahydrate to the above ethanol aqueous solution, adjust the pH value to 1-2, stir for 30min, and obtain transparent and uniform sol solution A. Dissolve 1.056 g of diammonium hydrogen phosphate and 2.5 g of PEG in 50 ml of deionized water to obtain a clear and transparent solution B. Slowly add the sol solution A to the solution B dropwise, stir for 30 minutes, slowly add 28% ammonia water dropwise therein under constant stirring, and adjust the pH to 10-11 after a milky white precipitate appears. Centrifuge, freeze-dry, and heat-treat at 600-800°C in a muffle furnace for 3 hours to obtain hollow bioactive glass powder.

Embodiment 2

[0036] 0.5g chitosan was added into 20ml 2% boric acid aqueous solution to prepare 2.5% chitosan aqueous solution, and 40ml ethanol was added. Add 10.42g of tetraethyl orthosilicate and 10.86g of calcium nitrate tetrahydrate to the above aqueous ethanol solution, adjust the pH value to 1-2, stir for 30min, and obtain a transparent and uniform sol solution A. Dissolve 1.056 g of diammonium hydrogen phosphate in 20 ml of deionized water, add 1 g of PVA, and stir until it is completely dissolved to obtain a clear and transparent solution B. Slowly add the sol solution A to the solution B, stir for 30 minutes, drop 1.5mol / L NaOH solution drop by drop under constant stirring, wait until the pH reaches 10-11, after the reaction is complete, centrifuge to obtain a white precipitate, which is freeze-dried 1. High-temperature heat treatment at 600° C. for 3 hours in a muffle furnace to obtain hollow bioactive glass powder.

Embodiment 3

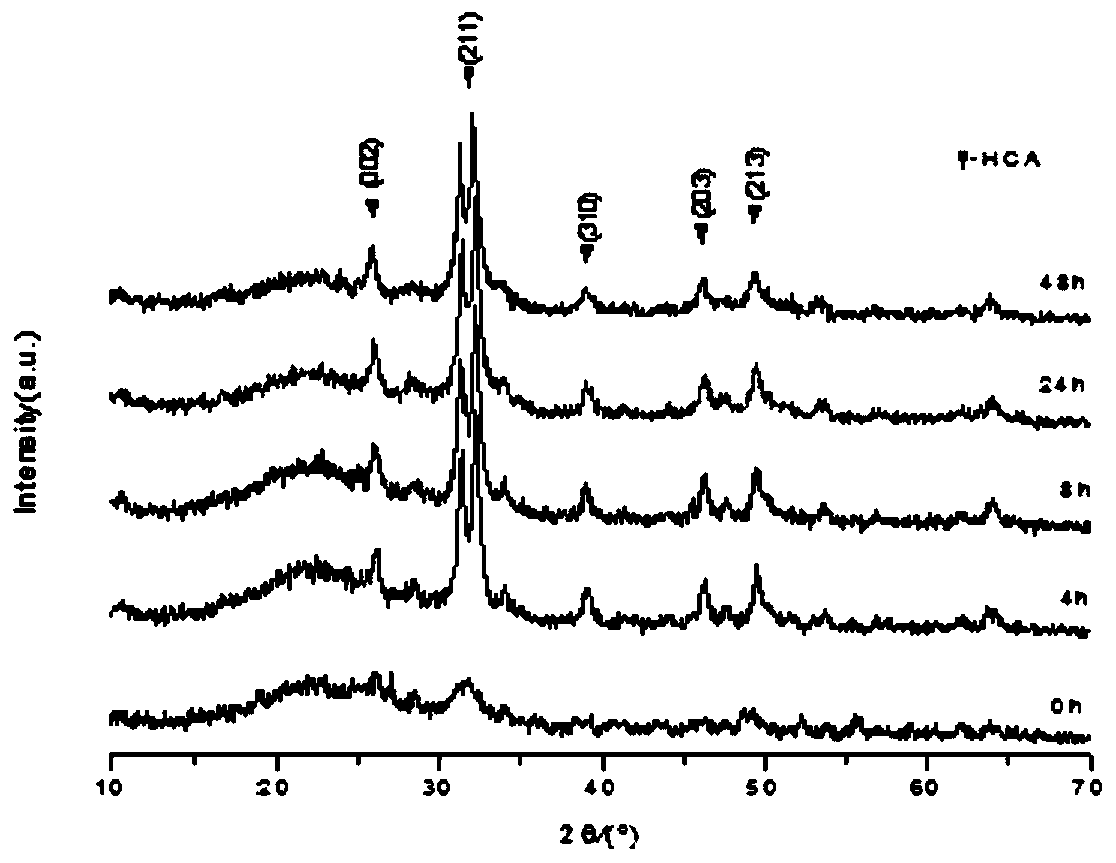

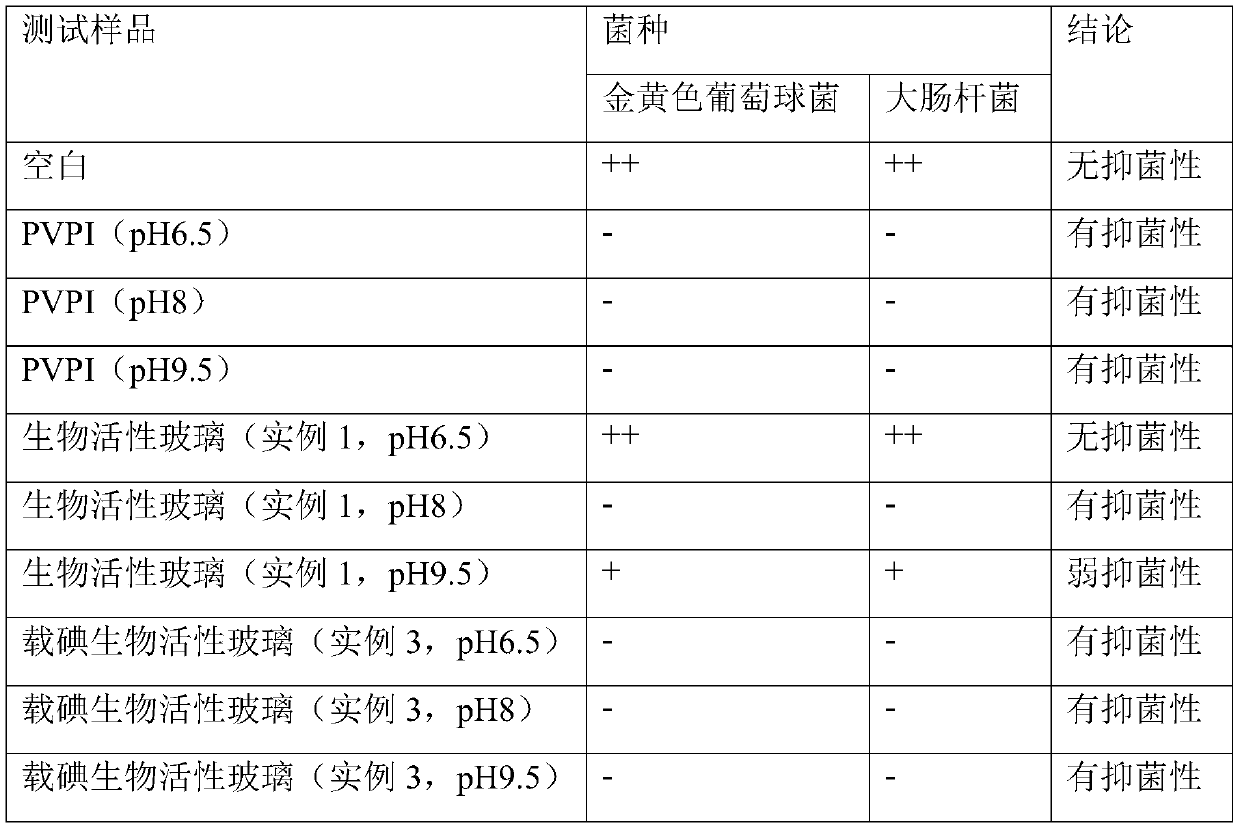

[0038] Put the hollow bioactive glass into a vacuum drying oven, and dry it under vacuum at 100°C for 1 hour; seal the iodine particles and grind them into fine powder; weigh the iodine and the bioactive glass according to the mass ratio of 0.5:1, and vortex mix them for 5-10 minutes to make a mixture; Weigh 1g of the mixture into a 5ml glass ampoule and fill it with N 2 Gas, melt seal; place the drug-loaded ampoule in a temperature-controlled heater, set the temperature at 60°C and heat for 90 minutes; take the sample out of the ampoule, and pass through a 200-mesh sieve to obtain iodine-loaded bioactive glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com