Porous organic composite loaded with palladium nanoparticles in situ, synthesis method and application

The technology of a palladium nanoparticle and a synthesis method, which is applied in the field of catalyst preparation, can solve the problems of difficult functional modification, difficulty in obtaining, and low stability of PdNP, and achieves the effects of short reaction time, easy recovery, and no need for inert gas protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

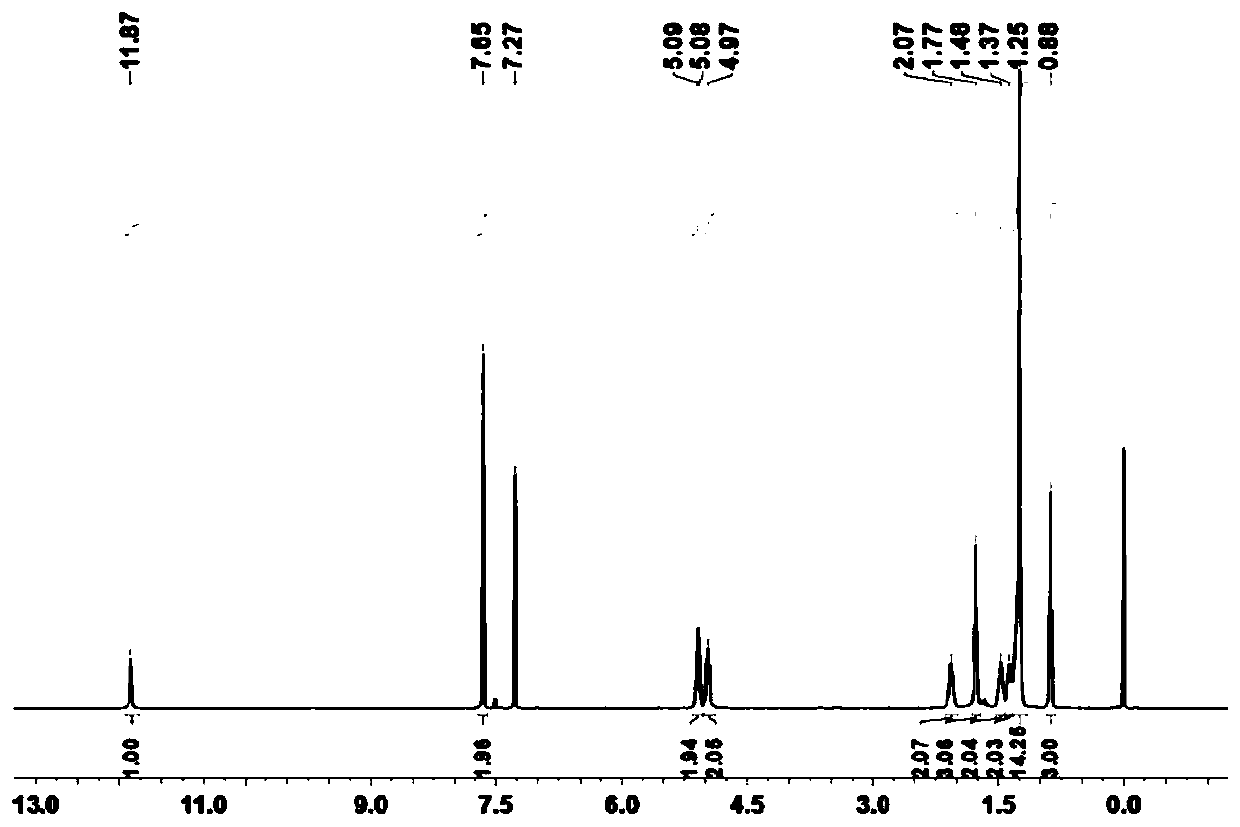

[0082] Example 1: Preparation of Imidazolium Ligand A.

[0083] Concrete preparation steps are as follows:

[0084] (1) Mix 4,7-dibromo-2,1,3-benzothiadiazole (5.86g, 20mmol) and cobalt chloride hexahydrate (48mg, 0.2mmol, 1mol%) in ethanol / tetrahydrofuran (110mL / 50mL) of the mixed solution was heated to reflux, followed by the addition of NaBH 4 (2.27g, 60mmol) (due to the exothermic reaction, NaBH 4 The temperature should be lowered and added carefully and slowly several times), and the reflux reaction was continued for 6h, which was monitored by TLC. Cool to room temperature after the reaction, add 80 mL of water to the system, stir for several minutes, then filter the precipitate, and remove the organic solvent by rotary evaporation. Dichloromethane (3 x 80 mL) was extracted and the combined organic phases were washed with brine and dried over anhydrous magnesium sulfate. The crude product was purified by column chromatography (petroleum ether: ethyl acetate = 5:1) to...

Embodiment 2

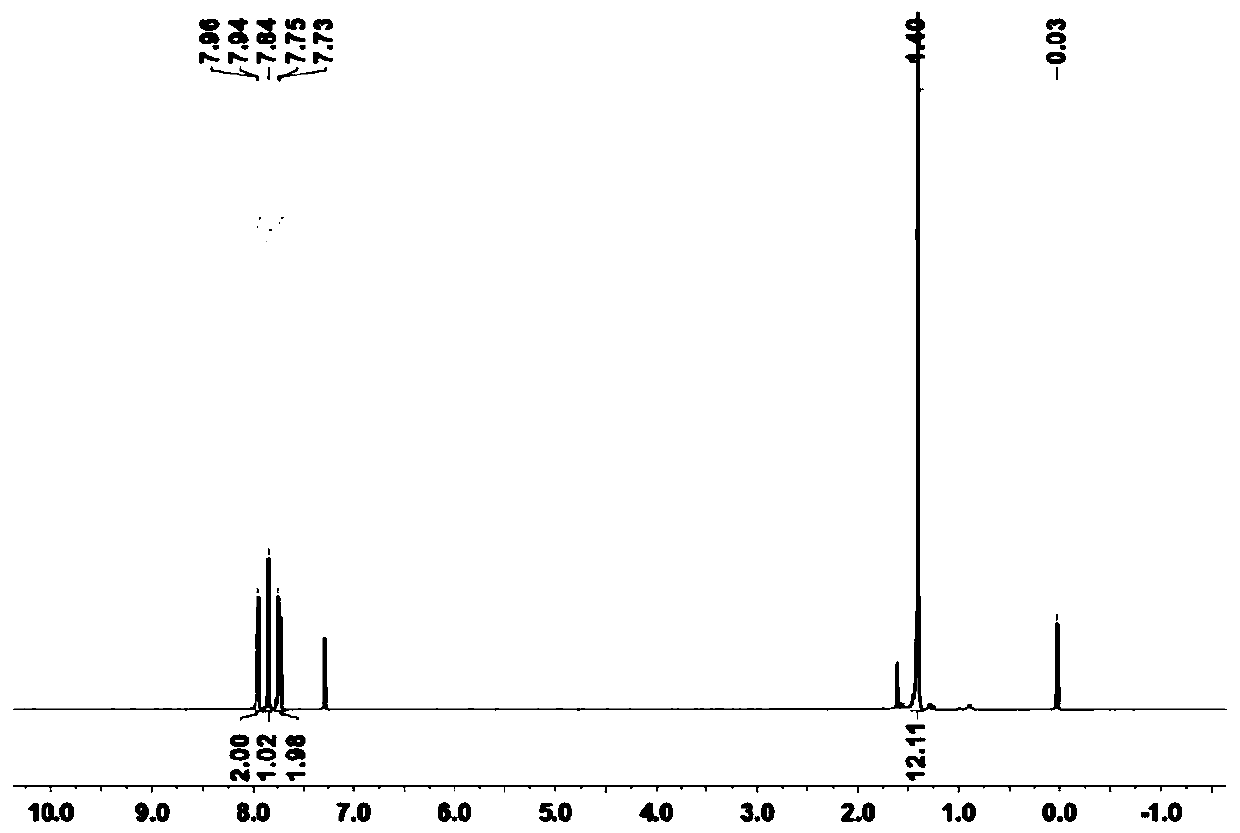

[0091] Example 2: Preparation of boronate ligand B.

[0092] Concrete preparation steps are as follows:

[0093] (1) in N 2 Under protection, SiCl was added dropwise to a 250 mL round bottom flask containing 4-bromoacetophenone (5.98 g, 30 mmol) in absolute ethanol (60 mL) at 0 °C 4 (7.1 mL, 60 mmol), kept stirring at 0°C for 1 h, then stirred at room temperature for 24 h. After the reaction was completed, 100 mL of water was added to the system, dichloromethane (3 × 100 mL) was extracted, the combined organic phase was dried with anhydrous magnesium sulfate, the organic solvent was removed by rotary evaporation, and then recrystallized in ethanol to obtain intermediate compound 4 ( 4.38 g, 81%) as a white solid.

[0094] (2) Intermediate compound 4 (2.17g, 4mmol), double pinacol borate (4.57g, 18mmol), potassium acetate (5.89g, 60mmol), PdCl 2 (dppf) (0.59g, 0.8mmol) was added to a 250mL round bottom flask, N 2 DMF (60 mL) was added under protection, heated to 80° C. for...

Embodiment 3

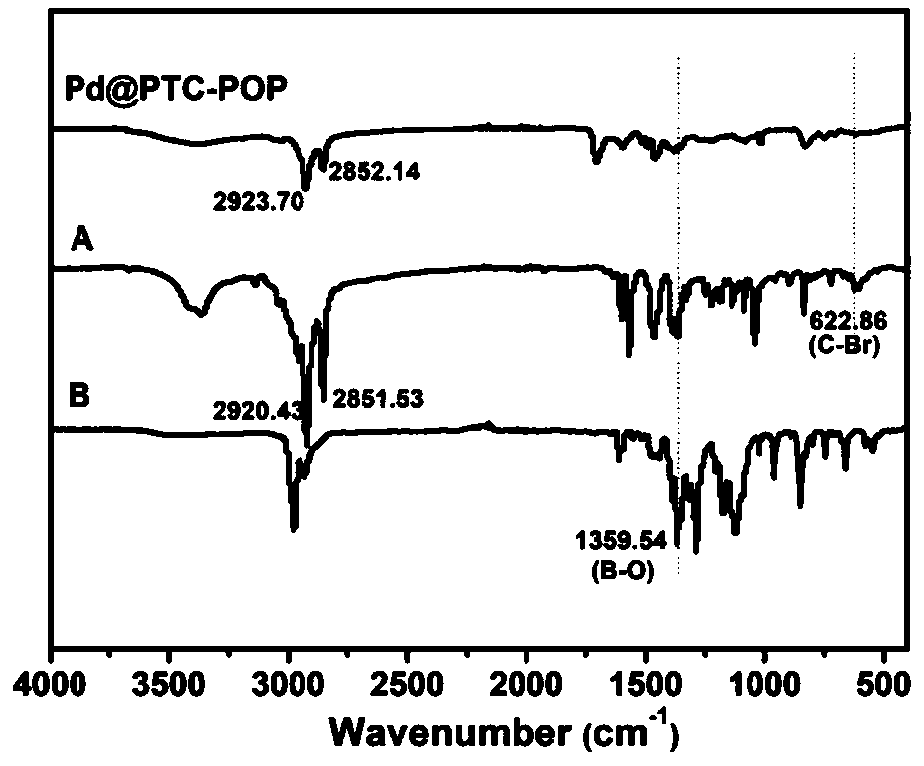

[0097] Example 3: Synthesis of Pd@PTC-POP.

[0098] Add imidazolate ligand A (664mg, 1.2mmol) and boronate ligand B (550mg, 0.8mmol) and catalyst Pd (PPh 3 ) 4 (0.14g, 0.12mmol), after N 2 Add DMF (120mL) and K by injection under protection 2 CO 3 Aqueous solution (10mL, 2M), heated to 110°C for 72h, cooled to room temperature after the reaction, filtered and washed with DMF, H 2 O and MeOH were washed to obtain a crude product, and the resulting solid crude product was repeatedly extracted with dichloromethane for 48 h through a Soxhlet extractor. After the extraction was completed, it was dried in vacuum at 110 ° C to obtain the final product Pd@PTC-POP, which was a dark gray solid ( 0.32g, 45%, weight average molecular weight is 3911).

[0099] The Pd@PTC-POP materials were carried out including infrared spectroscopy (IR), powder X-ray diffraction (PXRD), scanning electron microscopy (SEM), XPS spectroscopy, high-resolution transmission electron microscopy (HRTEM), sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com