Environmental-friendly solution capable of inhibiting generation rate of tetravalent tin

A generation rate, tetravalent tin technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of unsuitable SMT rework, high storage conditions, easy penetration and plating, etc., to reduce oxidation The risk of forming tetravalent tin, the effect of excellent compatibility and strong complexing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

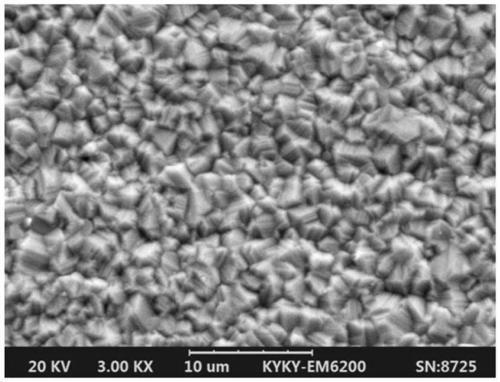

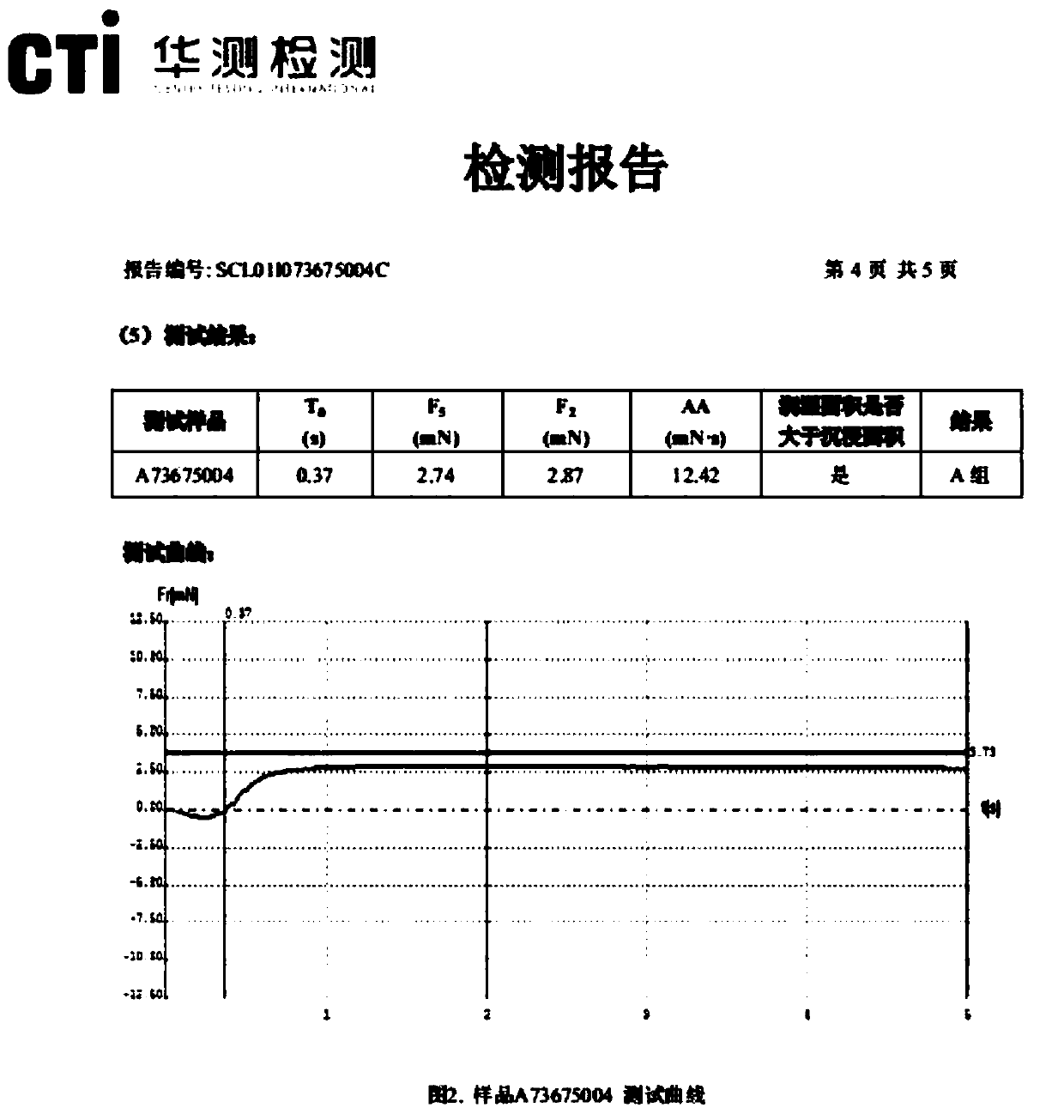

[0032] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The solution that the environment-friendly type of the present invention can suppress the generation rate of tetravalent tin comprises the following components according to the concentration:

[0034] Stannous ion 10-30g / L; stannous ion is the source of tin plating;

[0035] Thiourea 70-130g / L; Thiourea can greatly reduce the chemical potential of copper, so that the replacement reaction of tin and copper can proceed smoothly;

[0036] Methanesulfonic acid 30-70g / L; Methanesulfonic acid provides an acidic environment for the electroless tin plating solution;

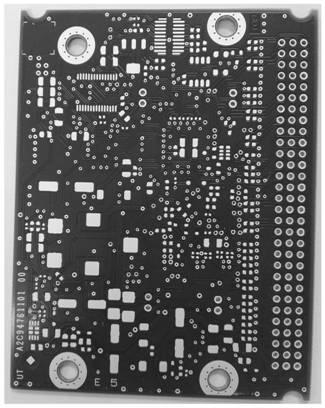

[0037] Surfactant 10-50mg / L; The surfactant can effectively reduce the surface tension of the solution, so that the plating solution can smoothly enter the through hole or blind hole of the circuit board;

[0038] Sodium hexametaphosphate 30-60g / L; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com