Two-dimensional metal organic skeleton composite membrane material, and preparation method and application

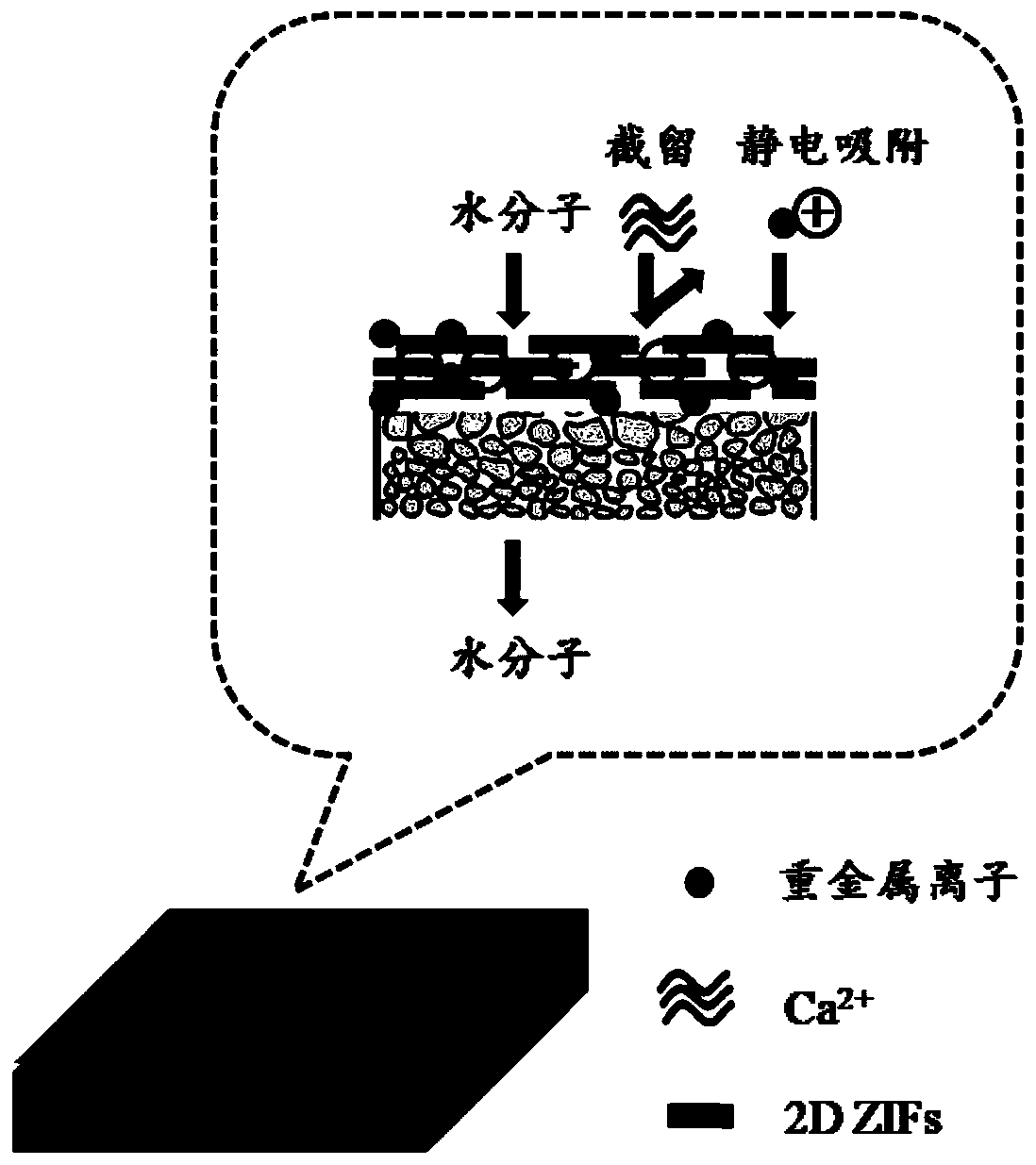

A metal-organic framework and composite membrane technology, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as poor dispersion, poor membrane hydrophilicity, and low membrane efficiency, and achieve Increased adsorption capacity, improved cross-linking and sedimentation, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the two-dimensional metal-organic framework composite membrane material of this embodiment includes the following steps:

[0042] (1) After zinc acetate, dimethylimidazole and N,N'-dimethylformamide are mixed and dissolved in a molar ratio of 0.8:0.3:110, react at room temperature for 1 day, and the obtained mixed product is washed with water and methanol After repeated washing, the solid product was separated and dried to obtain granular ZIFs;

[0043] (2) After mixing granular ZIFs, ethanol, and n-hexane according to the molar ratio of 0.23:225:250, grind and react at room temperature for 3 hours, and separate the upper suspension from the obtained colloidal solution through chemical precipitation, and dry to obtain two Dimensional metal-organic framework coordination polymers;

[0044] (3) Mix polyvinylpyrrolidone, polyvinylidene fluoride, dimethylacetamide, and potassium chloride in a molar ratio of 0.3:7.5:36, heat and stir at 50°C for 36...

Embodiment 2

[0047] The preparation method of the two-dimensional metal-organic framework composite membrane material of this embodiment comprises the following steps:

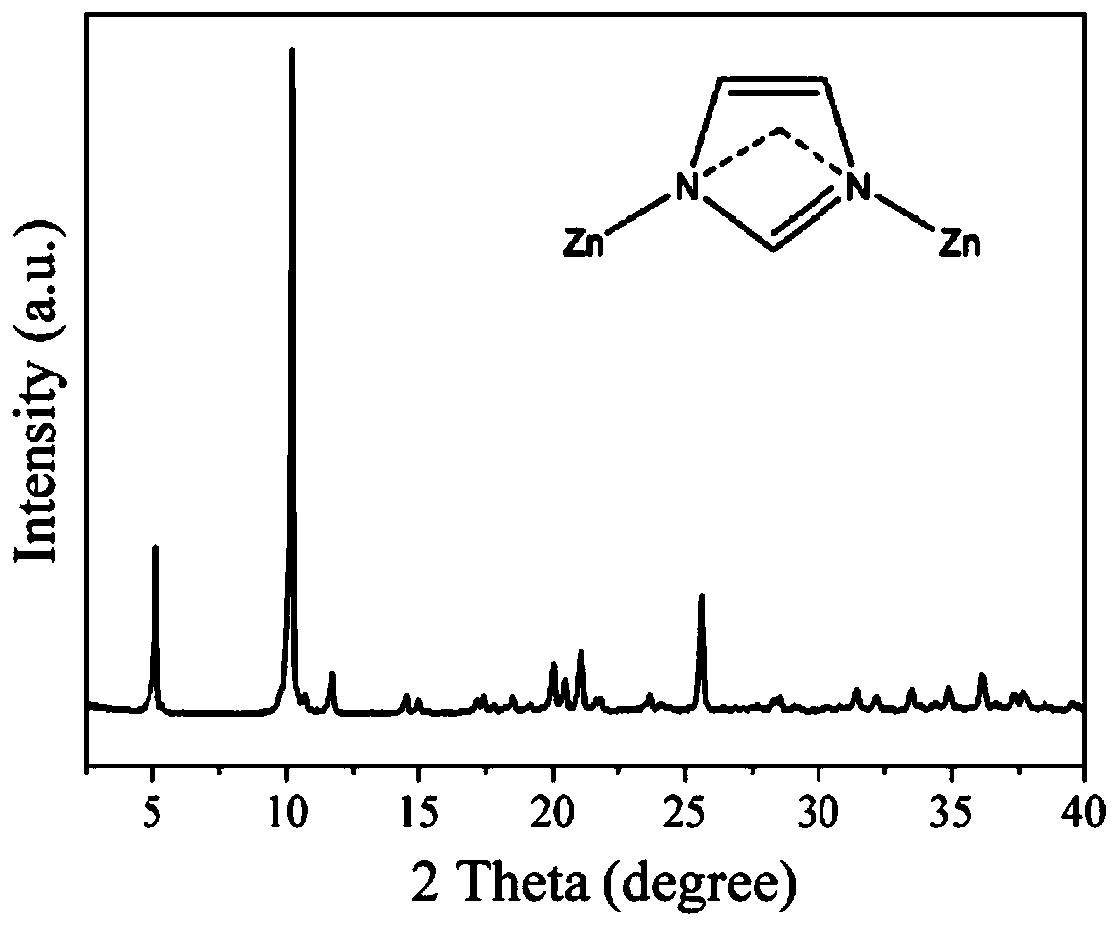

[0048] (1) After zinc acetate, dimethylimidazole and N,N'-dimethylformamide are mixed and dissolved in a molar ratio of 1.2:0.7:150, react at room temperature for 2 days, and the obtained mixed product is washed with water and methanol After repeated washing, the solid product was separated and dried to obtain granular ZIFs; as figure 2 Shown: The XRD test and analysis of the granular ZIFs shows that the granular ZIFs have an octahedral structure and a lattice configuration of 2MI-Zn-2MI.

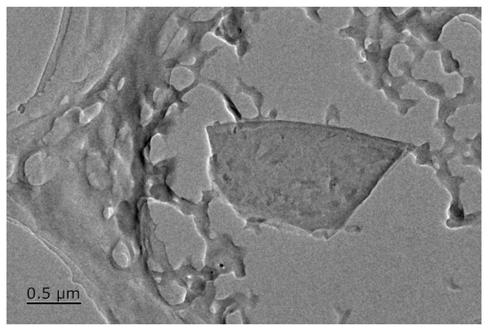

[0049] (2) After mixing granular ZIFs, ethanol, and n-hexane according to the molar ratio of 0.35:235:260, grind and react at room temperature for 2 hours, and separate the upper suspension from the obtained colloidal solution through chemical precipitation, and dry to obtain two Dimensional metal-organic framework coordination polyme...

Embodiment 3

[0058] The preparation method of the two-dimensional metal-organic framework composite membrane material of this embodiment includes the following steps:

[0059] (1) After zinc acetate, dimethylimidazole, and N,N'-dimethylformamide were mixed and dissolved in a molar ratio of 1.0:0.5:130, they were reacted at room temperature for 1.5 days, and the resulting mixed product was repeatedly washed with water and methanol. After washing, the solid product was separated and dried to obtain granular ZIFs;

[0060] (2) After mixing granular ZIFs, ethanol, and n-hexane according to the molar ratio of 0.27:231:256, grind and react at room temperature for 1 h, the obtained colloidal solution is separated by chemical precipitation, and the upper suspension is separated, and dried to obtain two Dimensional metal-organic framework coordination polymers;

[0061] (3) Mix polyvinylpyrrolidone, polyvinylidene fluoride, dimethylacetamide, and potassium chloride in a molar ratio of 0.5:8.6:37, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com