Lithium ion battery positive electrode material LiMnO2@C and preparation method thereof

A lithium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrochemical performance, and achieve high capacity retention, high purity, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

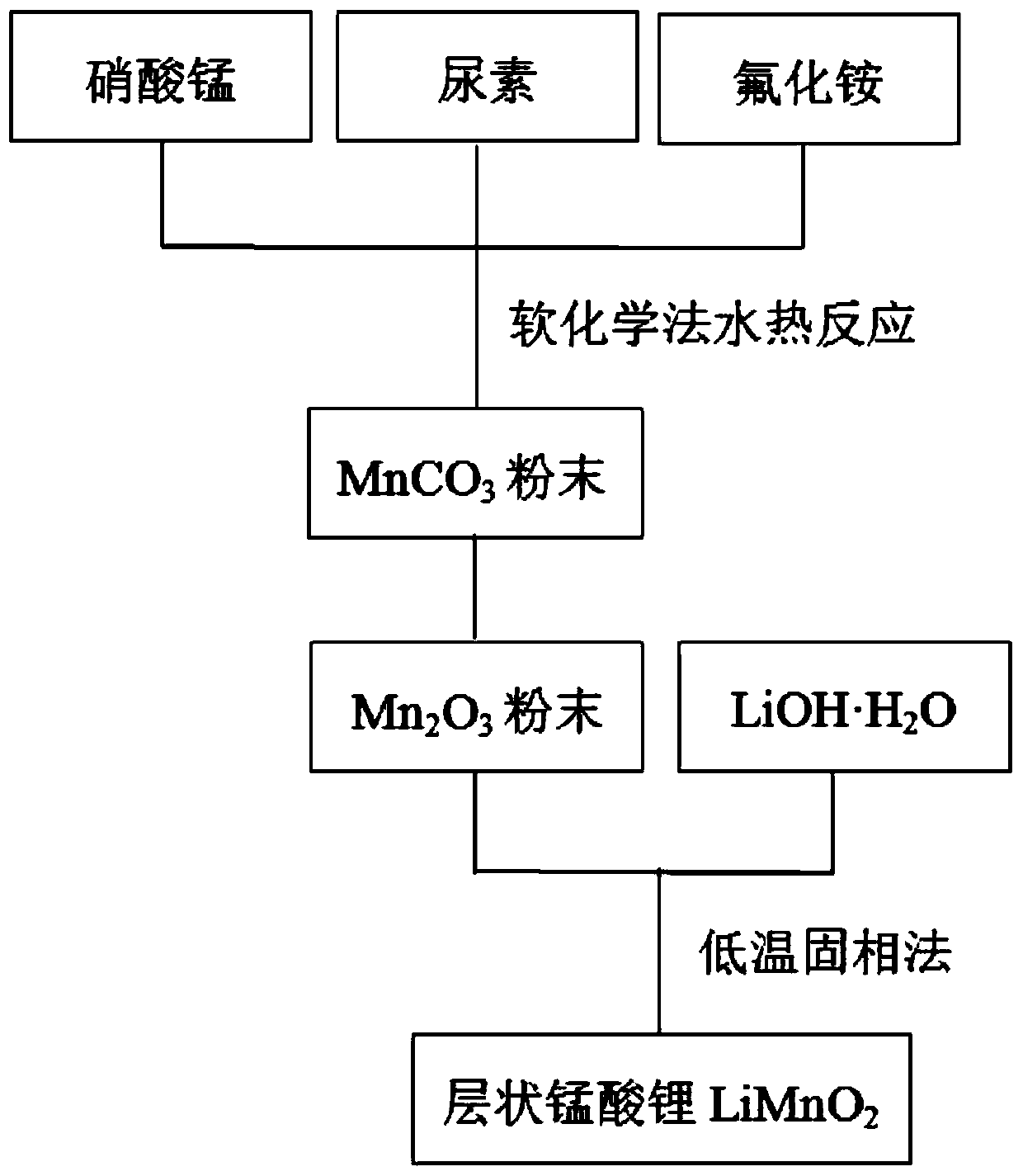

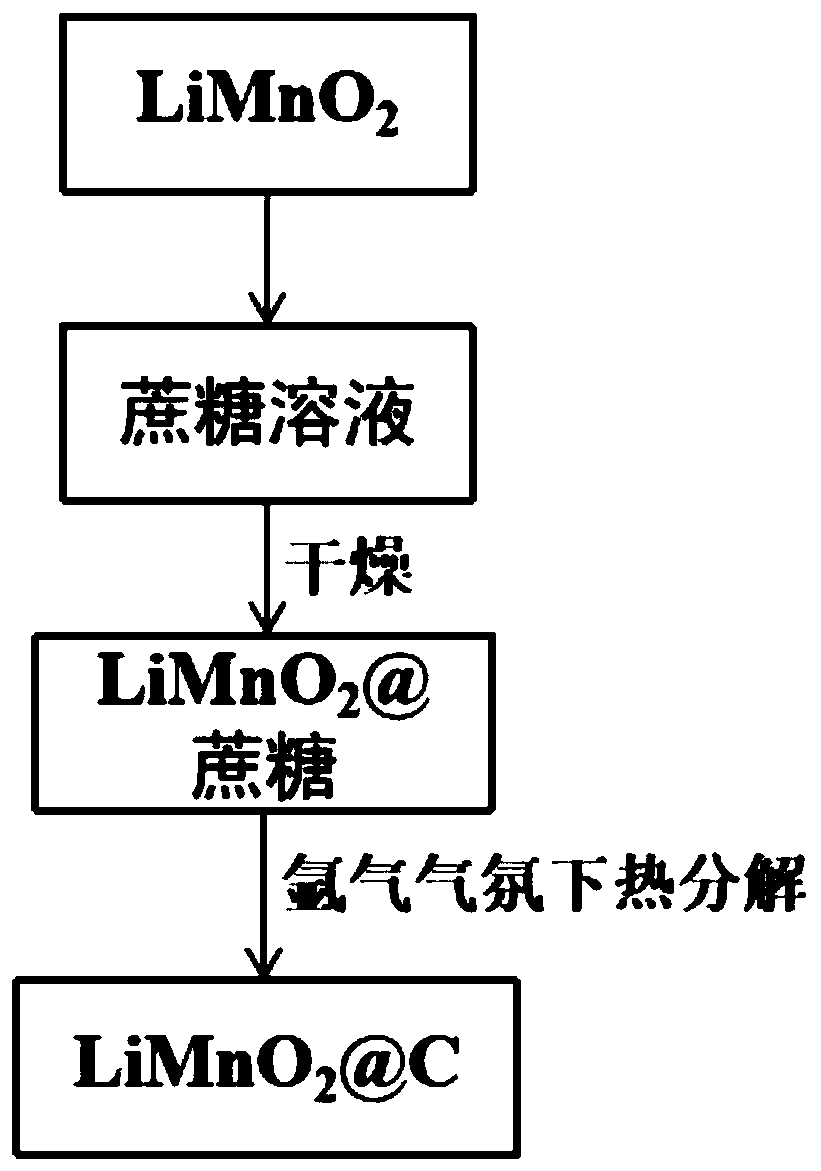

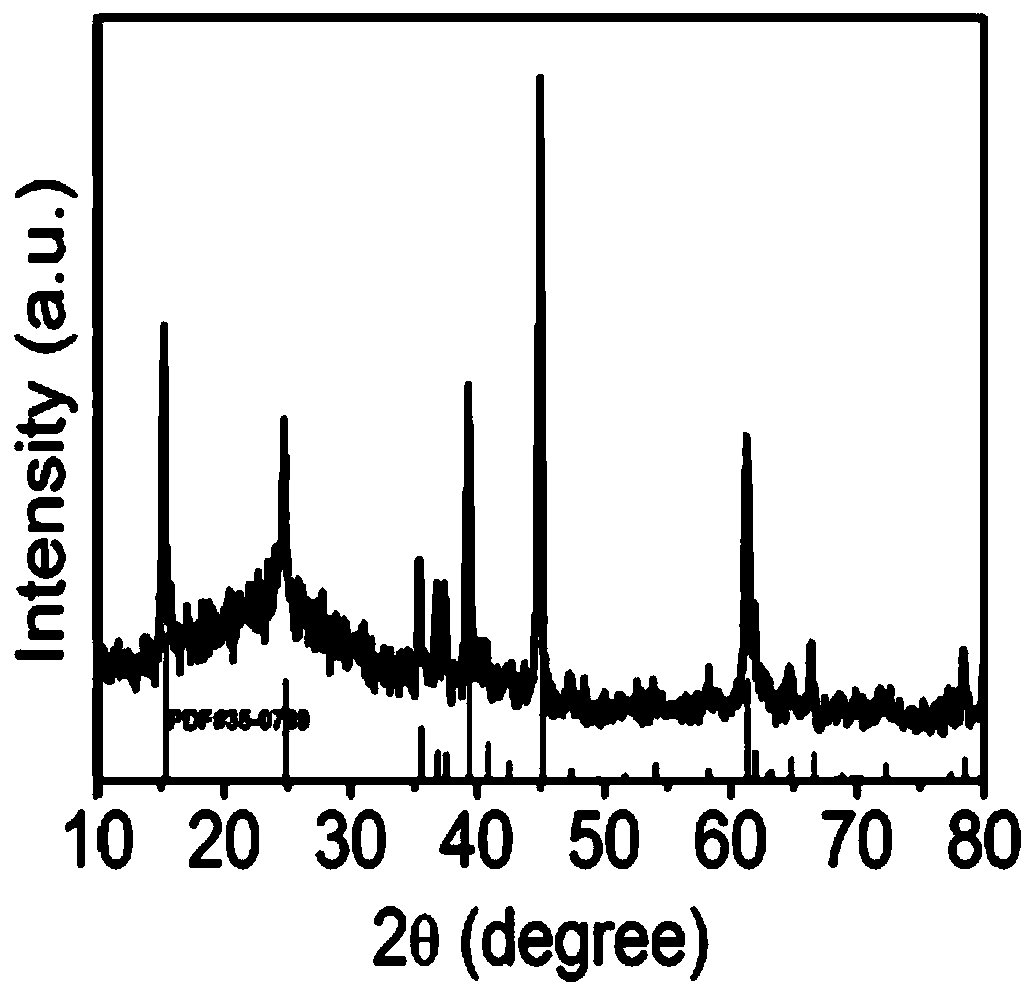

[0037] Add 0.1mol manganese nitrate to 100ml deionized water to configure solution A, add 0.4mol urea to 100ml deionized water to configure solution B, add 0.2mol ammonium fluoride to 100ml deionized water to configure solution C, and then mix Solution A, solution B and solution C are added into the beaker at a speed of 10ml / min at the same time, after adding, stir evenly and then transfer to a stainless steel autoclave lined with polytetrafluoroethylene, the filling capacity is 80%, and the autoclave is sealed. Hydrothermal reaction at 180 °C for 5 h, centrifugation, deionized water and ethanol cross-washing the precipitate three times each to obtain MnCO 3 White crystals precipitated; the MnCO 3 The white crystal precipitated product was placed in a forced air drying oven and dried at 90°C for 4h to obtain MnCO 3 White powder; MnCO 3 The white powder is placed in the air atmosphere of the muffle furnace and thermally decomposed at 450 ° C for 2 hours to obtain Mn 2 o 3 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com