Preparation method and applications of mesoporous organic silicon oxide-coated ferroferric oxide embospheres

A technology of triiron tetroxide and organic silicon oxide, which can be used in the preparation of microspheres, microcapsule preparations, and preparations for in vivo tests, etc. Great clinical translation value, uniform size, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

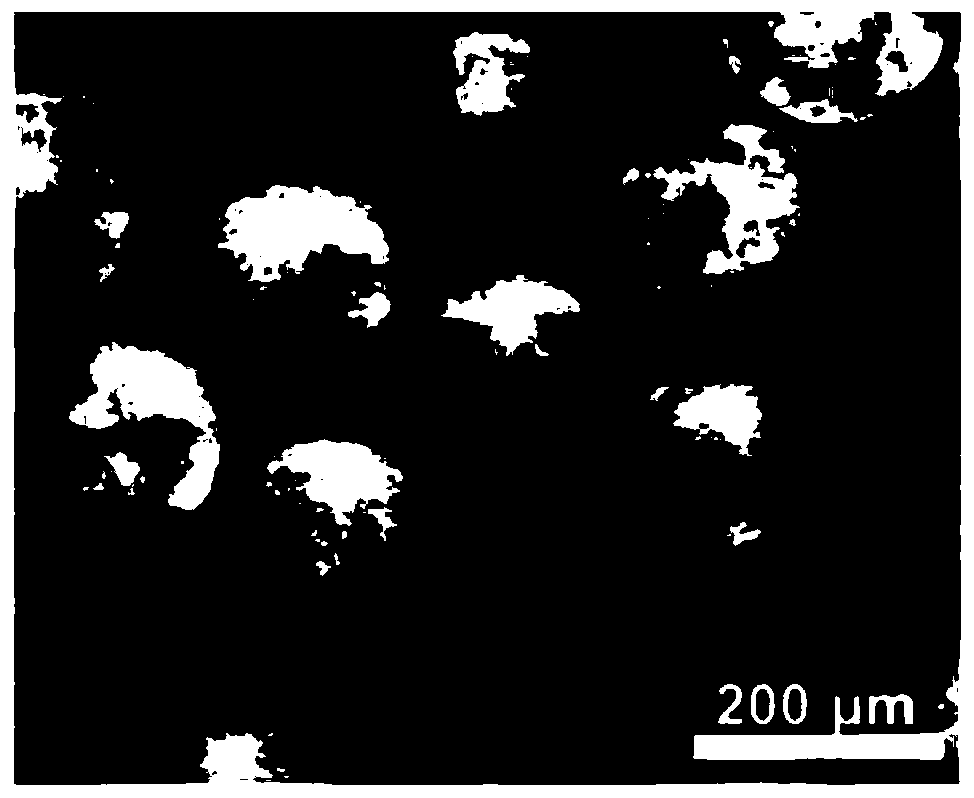

[0030] (1) Preparation of magnetic Fe by hot solvent method 3 o 4 Nanoparticles. The specific method is: 0.65g FeCl 3 , 0.2g sodium citrate, and 1.2g sodium acetate were dissolved in 20mL ethylene glycol and stirred evenly by magnetic force, then transferred to a 30mL reactor and reacted at 200°C for 10h, after cooling to room temperature, washed three times with deionized water, vacuum Oven drying for 12 hours to obtain magnetic ferric oxide particles;

[0031] (2) 0.2g of the above-prepared Fe 3 o 4 Nanoparticles were dispersed in 800mL water-alcohol solution (alcohol-water ratio 3:1), ultrasonically dispersed, then 10mL 25wt% ammonia water and 100mL TEOS were added, stirred at room temperature for 6h, centrifuged and washed with ethanol three times;

[0032] (3) Disperse the product of the above (2) into 1000mL alcohol water solution, alcohol water 8:1, add 1g CTAB surfactant, stir at room temperature for 1h, add 5mL 25wt% ammonia water, 100mL TEOS+BTSE mixed silicon s...

Embodiment 2

[0037] (1) Preparation of magnetic Fe by hot solvent method 3 o 4 Nanoparticles: 0.65g FeCl 3 , 0.2g sodium citrate, and 1.2g sodium acetate were dissolved in 20mL ethylene glycol and stirred evenly by magnetic force, then transferred to a 30mL reactor and reacted at 200°C for 10h, after cooling to room temperature, washed three times with deionized water, 60°C Dry in a vacuum oven for 12 hours to obtain magnetic ferric oxide particles;

[0038](2) 0.2g of the above-prepared Fe 3 o 4 Nanoparticles were dispersed in 800mL hydroalcoholic solution, the volume ratio of ethanol and water was 3:1, ultrasonically dispersed, then 10mL 25wt% ammonia water and 100mL TEOS were added, stirred at room temperature for 6h, centrifuged, and washed with ethanol three times;

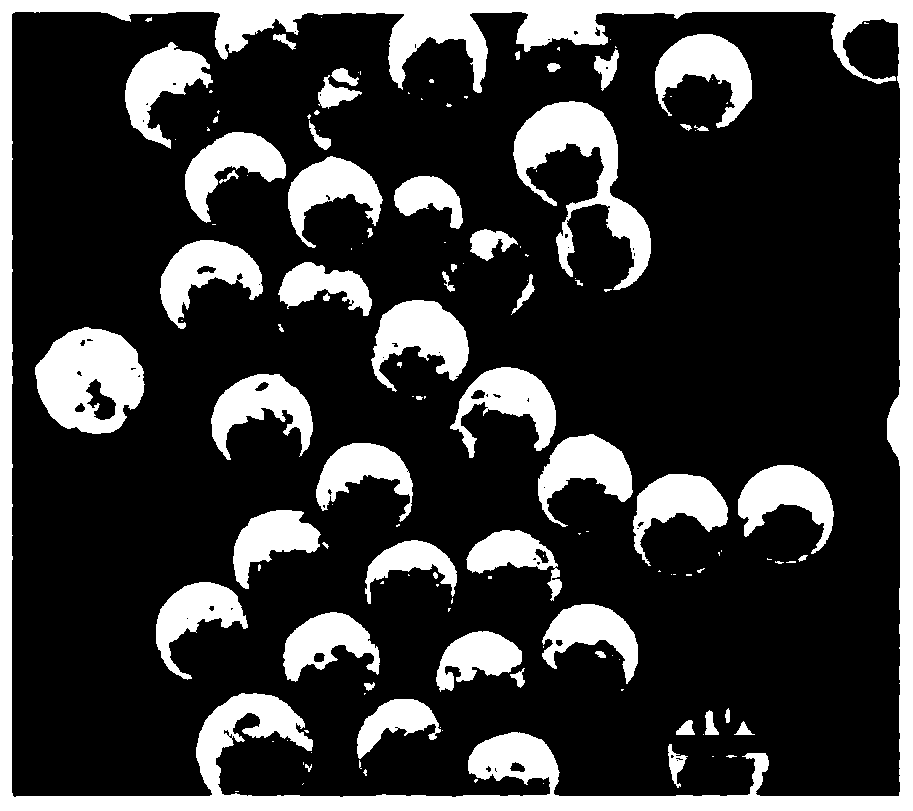

[0039] (3) Disperse the product of step 2 into 1000mL alcohol aqueous solution, the volume ratio of ethanol and water is 8:1, add 3gCTAB surfactant, stir at room temperature for 1h, add 15mL 25wt% ammonia water, 300mL...

Embodiment 3

[0043] (1) Preparation of magnetic Fe by hot solvent method 3 o 4 Nanoparticles: 0.65g FeCl 3 , 0.2g sodium citrate, and 1.2g sodium acetate were dissolved in 20mL ethylene glycol and stirred evenly by magnetic force, then transferred to a 30mL reactor and reacted at 200°C for 10h, after cooling to room temperature, washed three times with deionized water, 60°C Dry in a vacuum oven for 12 hours to obtain magnetic ferric oxide particles;

[0044] (2) 0.2g of the above-prepared Fe 3 o 4 Nanoparticles were dispersed in 800mL hydroalcoholic solution, the volume ratio of ethanol and water was 3:1, ultrasonically dispersed, then 10mL 25wt% ammonia water and 100mL TEOS were added, stirred at room temperature for 6h, centrifuged, and washed with ethanol three times;

[0045] (3) Disperse the product of step 2 into 1000mL alcohol aqueous solution, the volume ratio of ethanol and water is 4:1, add 3gCTAB surfactant, stir at room temperature for 1h, add 15mL 25wt% ammonia water, 300m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com