Sulfur-containing porous organic polymer material LNUs, preparation method and applications thereof

A polymer material and organic technology, applied in the field of sulfur-containing porous organic polymer materials, can solve the problems of complex design and preparation methods, limitations, poor stability of small molecules, etc., and achieve excellent thermochemical stability, wide applicability, good Effect of Pore Size and Specific Surface Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

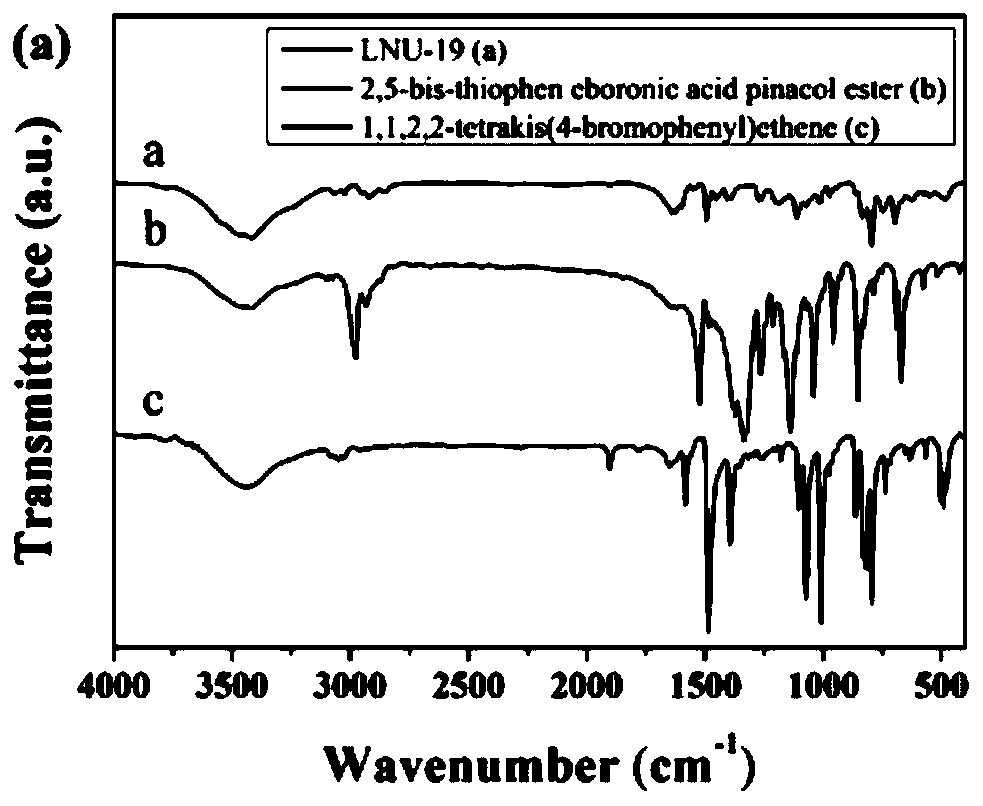

[0046] The preparation of embodiment 1 sulfur-containing porous organic polymer LNU-19

[0047] Place 337mg (0.52mmol) tetra-(4-bromophenyl)ethylene and 150mg (1.04mmol) thiophene-2,5-diboronic acid dipinacid in a 100mL round bottom flask, add 60mL of N,N' -Dimethylformamide organic solvent, and then use the freezing-degassing-ventilation process to repeat the cycle three times. Then 5 mL of 2M potassium carbonate aqueous solution and 40 mg of tetrakis(triphenylphosphine)palladium were quickly added to the reaction system. Then use the freezing-degassing-ventilation process to repeat the cycle three times. Then the temperature was raised to 130°C and the reaction was stirred for 48h. After the reaction, cool to room temperature, filter, and wash the obtained precipitate with water, tetrahydrofuran, dichloromethane and acetone in sequence. Reactants or catalysts that may remain in the product. The final product was dried under vacuum at 90° C. for 10 h, and the obtained yello...

Embodiment 2

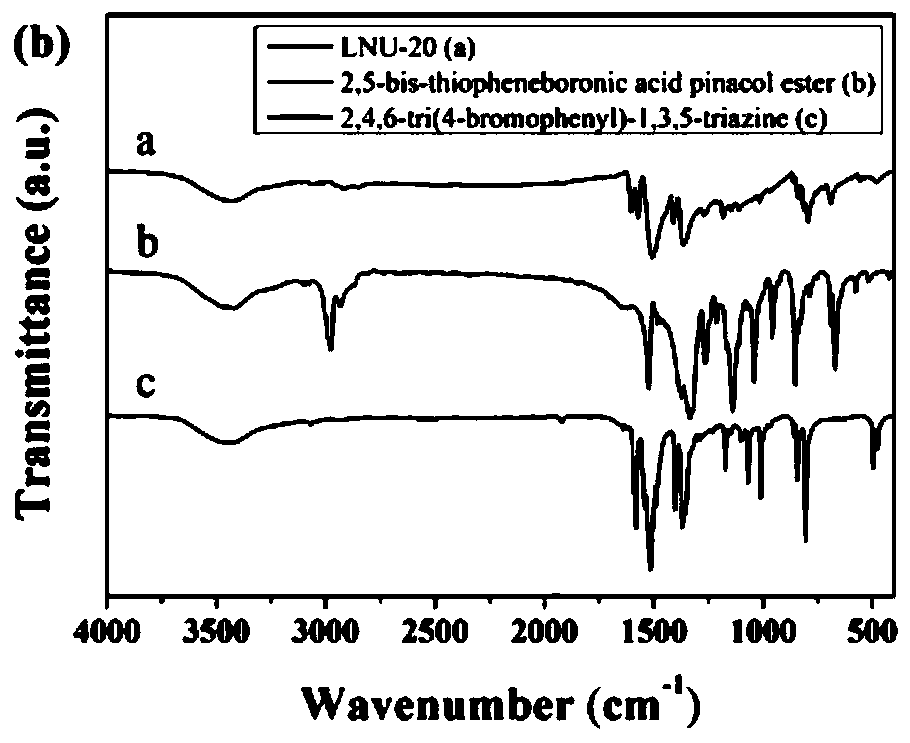

[0048] The preparation of embodiment 2 sulfur-containing porous organic polymer LNU-20

[0049] Replace 337 mg (0.52 mmol) of tetrakis-4-(bromophenyl)ethylene with 379 mg (0.52 mmol) of 2,4,6-tris(4-bromophenyl)-1,3,5-triazine, and the remaining steps Same as Example 1, the obtained dark green powder is the target sulfur-containing porous organic polymer material LNU-20.

Embodiment 3

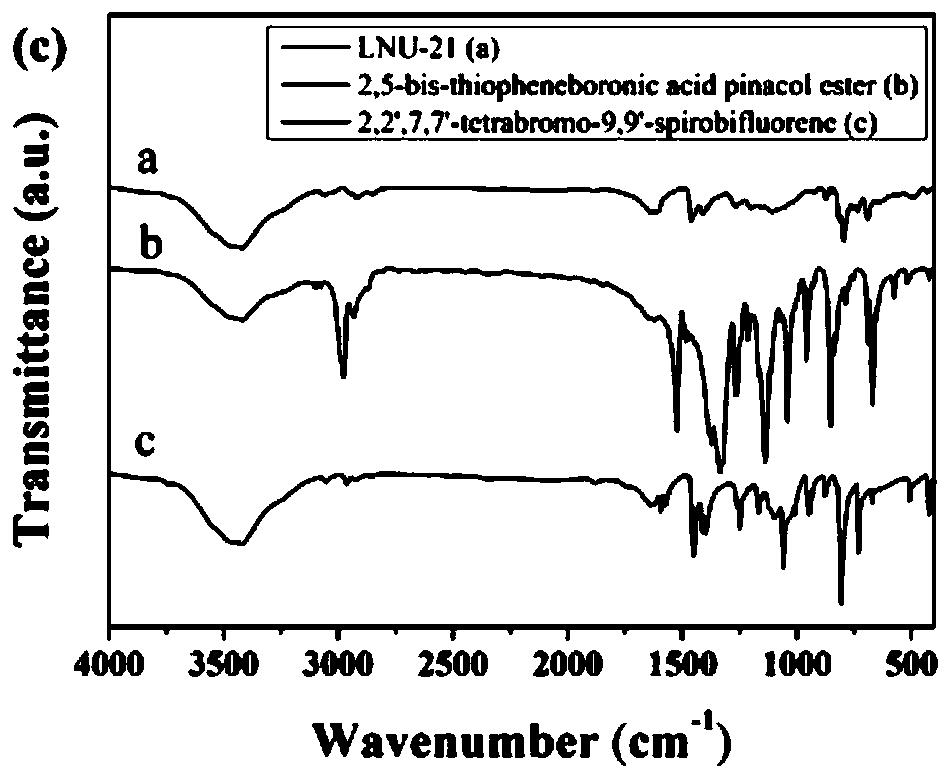

[0050] Preparation of Example 3 Sulfur Porous Organic Polymer LNU-21

[0051] Replace 337mg (0.52mmol) of tetra-4-(bromophenyl)ethylene with 330mg (0.52mmol) of 2,2',7,7'-tetrabromo-9,9'-spirobifluorene, and carry out the rest of the steps Example 1, the obtained green powder is the target sulfur-containing porous organic polymer material LNU-21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com