Preparation method of double-network chitosan hydrogel

A dual network, chitosan technology, applied in the field of chitosan hydrogel, can solve the problems of electrostatic interaction damage, hydrogel cytotoxicity, hydrogel network disintegration, etc., achieve good mechanical strength, expand in-depth research and practice applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

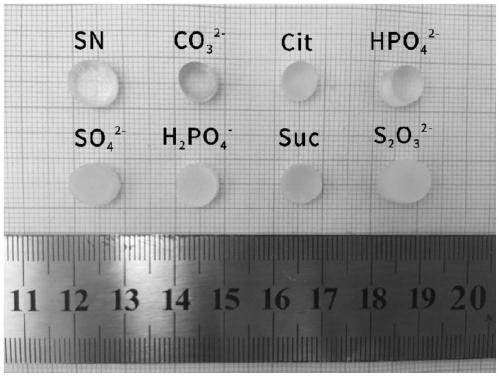

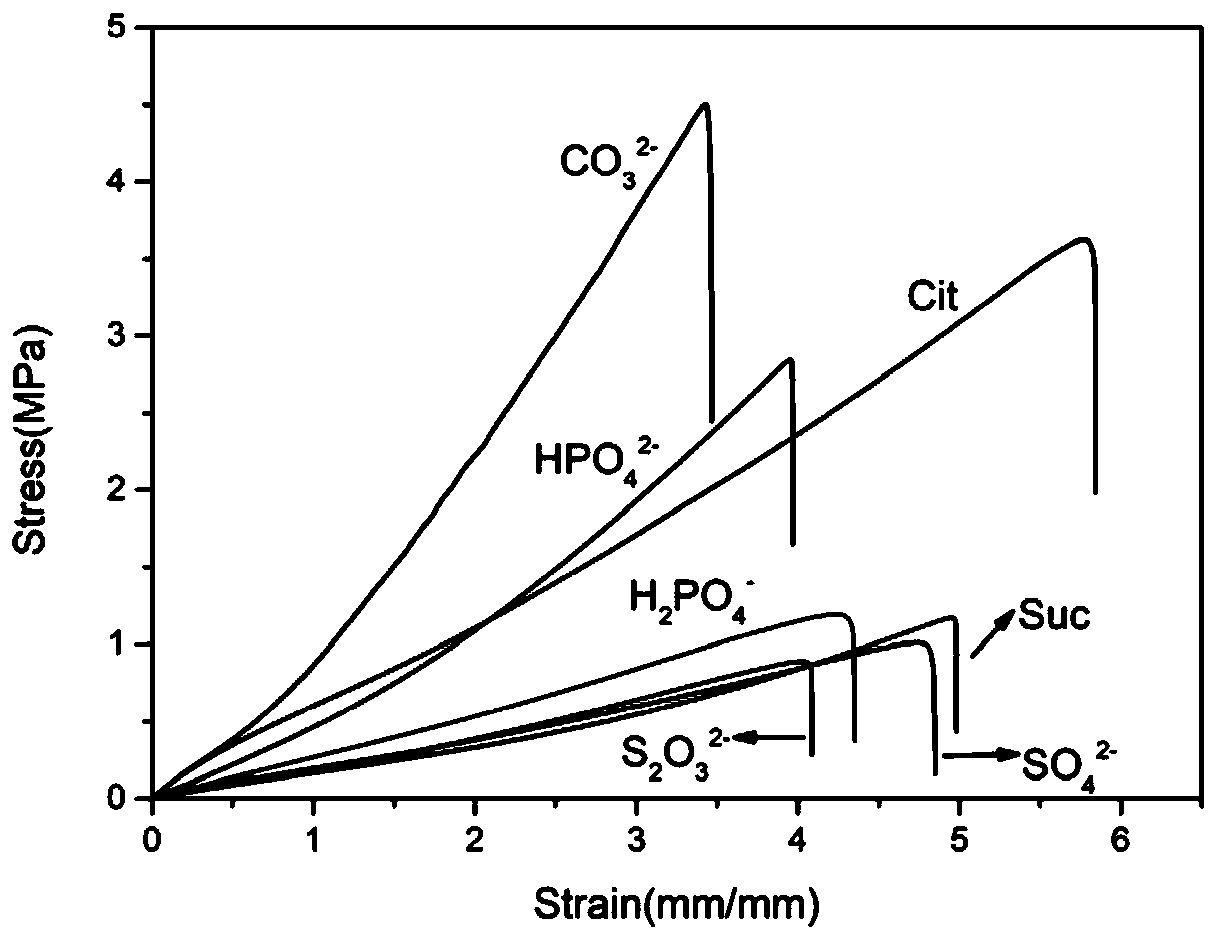

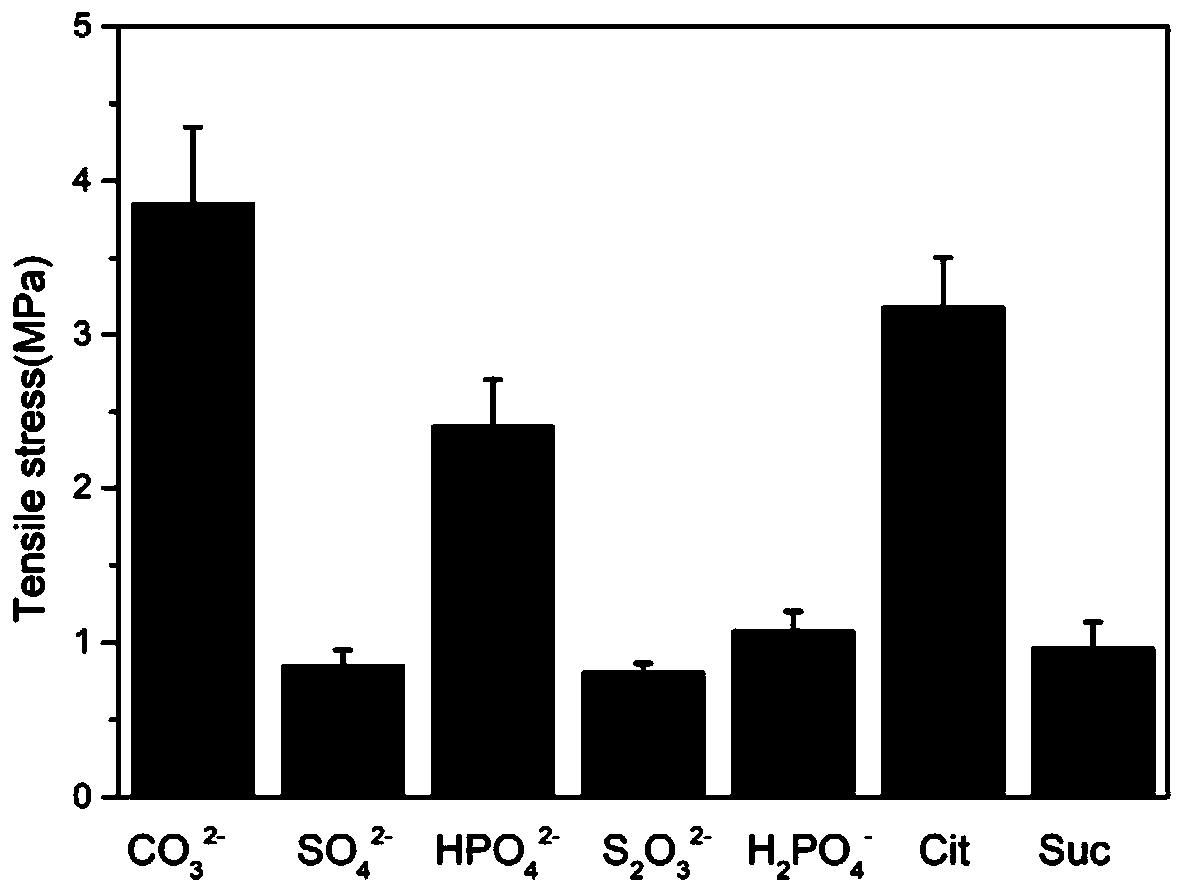

[0027] Pour 4.208ml of vinyltriethoxysilane into 30ml of deionized water and stir at room temperature for 12 hours to obtain a clear and transparent suspension of silica nanoparticles for use. Take 1ml of the above suspension, add it to 14ml deionized water, add 1.5g chitosan, 3g acrylamide, 94.6mg I2959, stir well, and place it at room temperature for 12 hours to eliminate air bubbles. The mixed solution was poured into a mold and subjected to ultraviolet light for 30 minutes to obtain a semi-interpenetrating network chitosan hydrogel. This hydrogel is soaked in 2mol / L saline solution (this saline solution can select potassium carbonate solution, sodium sulfate solution, dipotassium hydrogen phosphate trihydrate solution, sodium thiosulfate solution, sodium succinate solution, sodium citrate solution , sodium dihydrogen phosphate solution, and in the present embodiment preferred potassium carbonate solution) in 12h, obtain double network chitosan hydrogel. figure 1 It is a s...

Embodiment 2

[0029] Pour 4.208ml of vinyltriethoxysilane into 30ml of deionized water and stir at room temperature for 12 hours to obtain a clear and transparent suspension of silica nanoparticles for use. Take 1ml of the above suspension, add it to 14ml deionized water, add 0.6, 1.05 or 1.5g chitosan, 3g acrylamide, 94.6mg I2959, stir well, and place it at room temperature for 12 hours to eliminate air bubbles. The mixed solution was poured into a mold and subjected to ultraviolet light for 30 minutes to obtain a semi-interpenetrating network chitosan hydrogel. The hydrogel was soaked in 2mol / L potassium carbonate solution for 12 hours to obtain double network chitosan hydrogel. Image 6It shows that with the increase of the concentration of chitosan, the tensile strength of the double network hydrogel is obviously enhanced, which is mainly due to the rapid increase of the number of amino groups inside the hydrogel with the increase of the concentration of chitosan. The root ions formed ...

Embodiment 3

[0031] Pour 4.208ml of vinyltriethoxysilane into 30ml of deionized water and stir at room temperature for 12 hours to obtain a clear and transparent suspension of silica nanoparticles for use. Take 1ml of the above suspension, add it to 14ml deionized water, add 1.5g chitosan, 3g acrylamide, 94.6mg I2959, stir well, and place it at room temperature for 12 hours to eliminate air bubbles. The mixed solution was poured into a mold and subjected to ultraviolet light for 30 minutes to obtain a semi-interpenetrating network chitosan hydrogel. Soak the hydrogel in 0.5, 1.0, 1.5 or 2 mol / L potassium carbonate solution for 12 hours to obtain double network chitosan hydrogel. Figure 7 It shows that as the concentration of carbonate ions gradually increases, the tensile strength of the double network hydrogel tends to increase. When the concentration of carbonate is low, the difference in osmotic pressure between the inside and outside of the hydrogel is small. When water molecules ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com