Water-retention gel electrolyte, preparation method thereof, and water-based supercapacitor and preparation method and application thereof

A technology of supercapacitors and gel electrolytes, applied in electrolytic capacitors, hybrid/electric double-layer capacitor manufacturing, capacitors, etc., can solve the problems of restricting electrolytes and capacitors, explosions, and capacitor devices not working continuously, and achieve large-scale production. , the effect of excellent low vapor pressure, excellent water retention capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing the water-retaining gel electrolyte described in the above scheme, comprising the following steps:

[0045] Under the condition of heating, the aqueous electrolyte solution is mixed with the oxygen-containing functional group polymer, and the water-retaining gel electrolyte is obtained after cooling.

[0046] In the present invention, the heating temperature is 75-100° C., preferably 80-95° C.; in the present invention, the heating is preferably carried out in an oil bath. In the present invention, the mixing is preferably performed by adding the oxygen-containing functional group polymer into the aqueous electrolyte solution. In order to ensure better dissolution of the oxygen-containing functional group polymer, the present invention preferably adopts the method of gradually adding oxygen-containing functional groups, specifically: heating the electrolyte aqueous solution to the required temperature in an oil bath,...

Embodiment 1

[0062] A water-based supercapacitor based on a water-retaining gel electrolyte, the preparation method comprising the following steps:

[0063] 1) Nickel sheets cut into a size of 1cm×1cm and self-made activated carbon were used as current collectors and electrode materials, respectively;

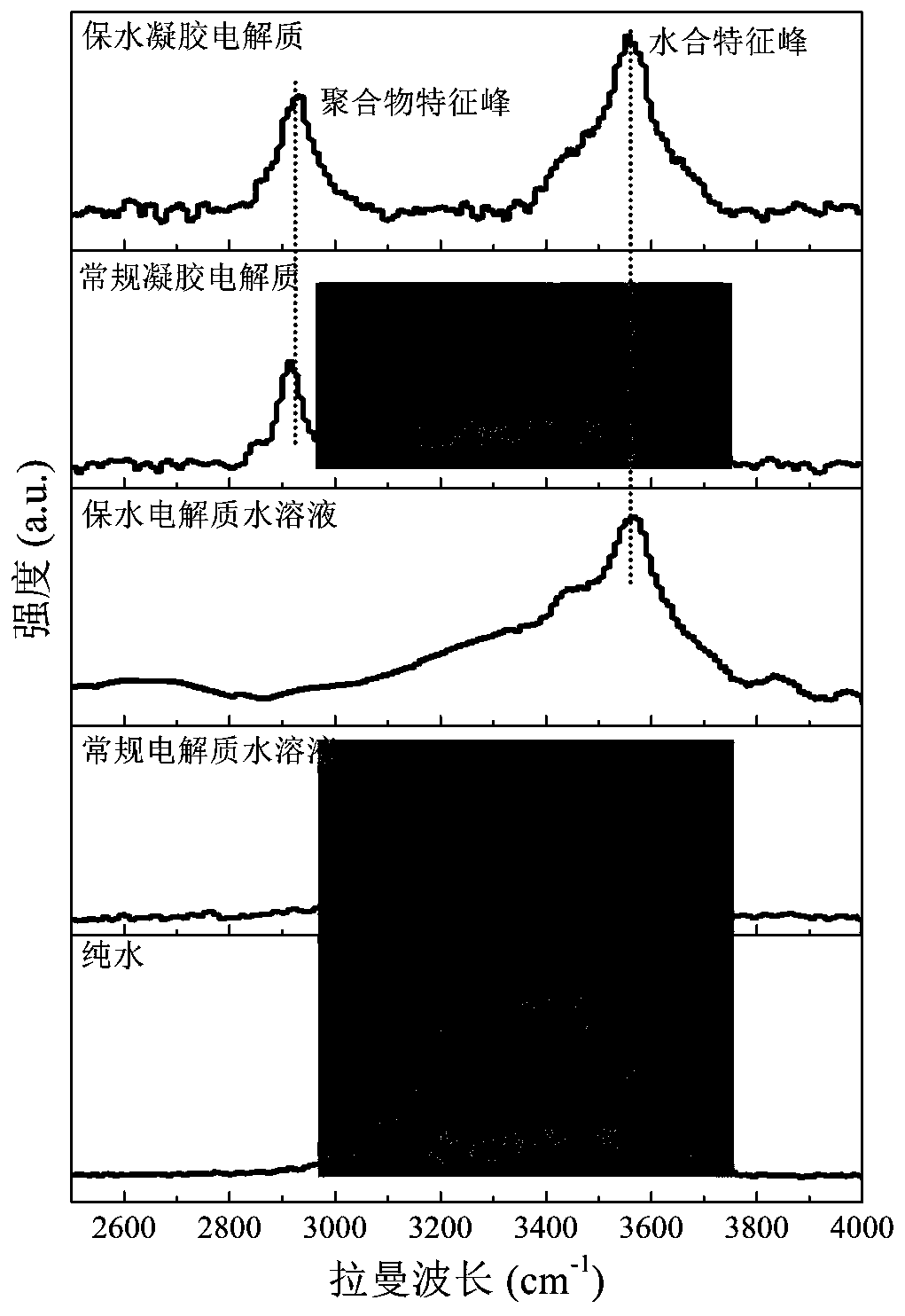

[0064] 2) Heat a 13mol / kg lithium perchlorate aqueous solution (that is, a water-retaining electrolyte aqueous solution) to 90°C, and then add polyacrylamide within 30 minutes under continuous stirring, and continue stirring for 4 hours to obtain a clear and transparent gel. Polyacrylamide The mass fraction in the gel is 8.36%. After cooling to room temperature, the water-retaining gel electrolyte is obtained, which is referred to as polyacrylamide-lithium perchlorate water-retaining gel electrolyte;

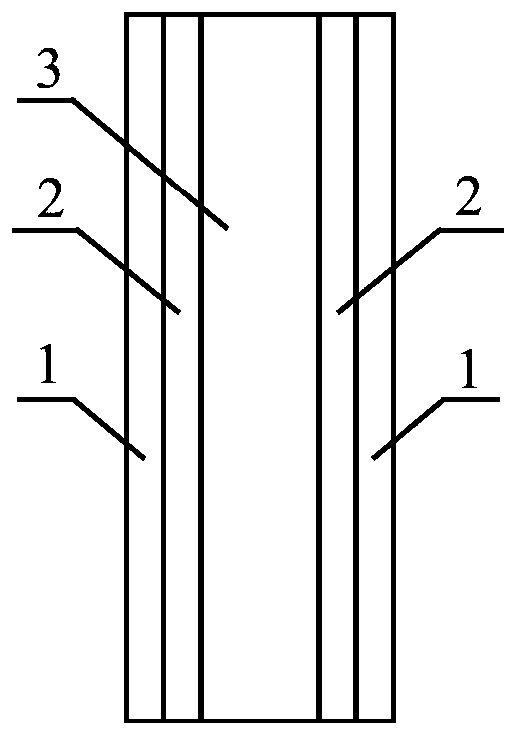

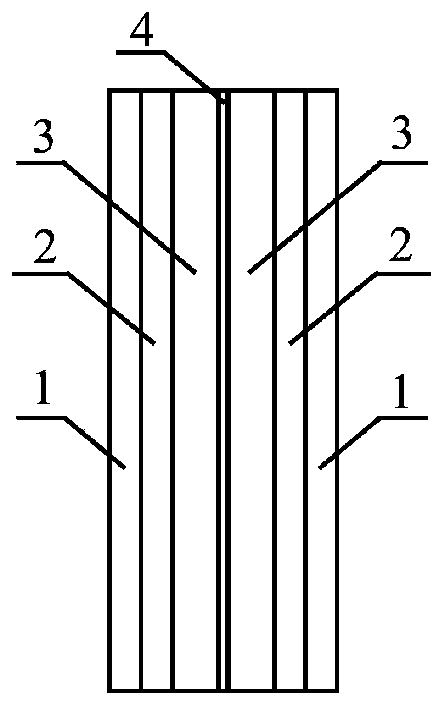

[0065] 3) The polyacrylamide-lithium perchlorate water-retaining gel electrolyte was evenly coated on the surface of the self-made activated carbon, and then assembled into a water-retaining...

Embodiment 2

[0078] A water-based supercapacitor based on a water-retaining gel electrolyte, the preparation method comprising the following steps:

[0079] 1) Zinc flakes and commercial activated carbon cut into a size of 1cm×1cm were used as current collectors and electrode materials, respectively;

[0080] 2) Heat the 15mol / kg potassium nitrate solution to 95°C, then add polyethylene glycol within 60 minutes under continuous stirring, and continue stirring for 6 hours to obtain a clear and transparent gel. The quality of polyethylene glycol in the gel is The fraction is 10.0%; after cooling to room temperature, a water-retaining gel electrolyte is obtained, which is recorded as polyethylene glycol-potassium nitrate water-retaining gel electrolyte;

[0081] 3) The polyethylene glycol-potassium nitrate water-retaining gel electrolyte is evenly coated on the surface of commercial activated carbon, and then assembled into a water-retaining gel electrolyte based on the structure of current c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com