Aqueous zinc ion secondary battery taking elemental sulfur or sulfide as positive electrode

A zinc-ion battery, elemental sulfur technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of poor conductivity, poor capacity utilization, low theoretical capacity of metal ferricyanide, etc., to improve discharge capacity and energy. density, meeting the requirements of large-scale applications, and the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

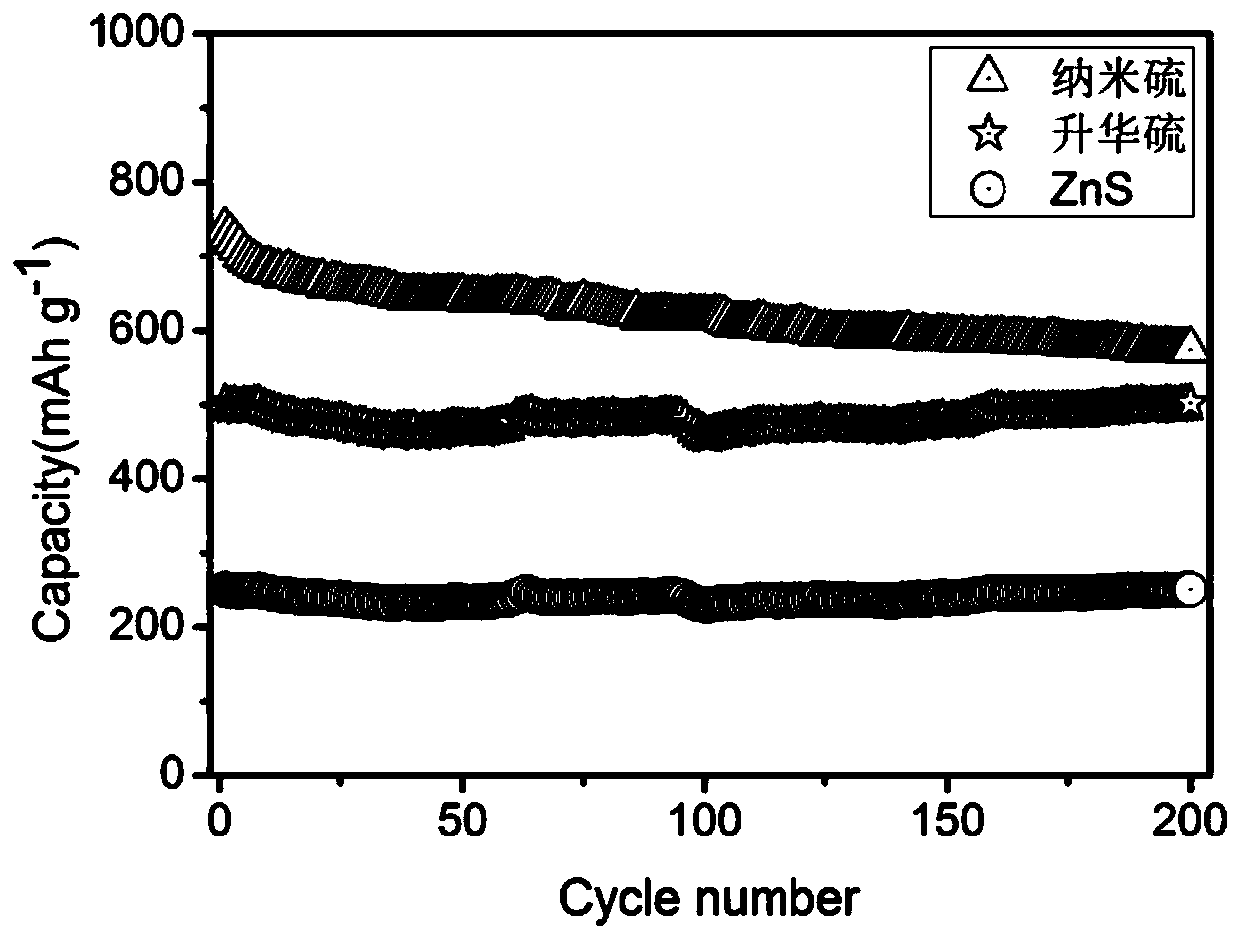

Embodiment 1

[0031] Sublimed sulfur is used as the positive electrode active material, and the positive electrode plate is assembled according to the mass ratio of sublimated sulfur: acetylene black: polyvinylidene fluoride, which is 5:3:2, and is evenly mixed, and ground until a uniformly mixed slightly fluid paste slurry is formed. , and then evenly spread the paste slurry on a stainless steel foil of appropriate size, and finally leave it in an oven at 80°C for 12 hours, and then cut it into a sheet of appropriate size as the positive electrode of the battery. The negative electrode is high-purity zinc foil, which is soaked in absolute ethanol for 1 hour, and cut into pieces of appropriate size as the negative electrode. With a concentration of 3mol / L ZnSO 4 The aqueous solution is the electrolyte. The separator is a composite film assembled from polyethylene, polypropylene and polyethylene, and finally the prepared positive electrode, negative electrode, separator and electrolyte are ...

Embodiment 2

[0033] Settled sulfur is used as the positive electrode active material, and the positive electrode plate is assembled according to the mass ratio of settled sulfur: acetylene black: polyvinylidene fluoride is 8:1:1, and is evenly mixed, and ground with an agate mortar until a uniform mixture with slight fluidity is formed. Then spread the paste slurry evenly on a stainless steel foil of appropriate size, and finally dry it in an oven at 100°C for 15 hours, and cut it into a sheet of appropriate size as the positive electrode of the battery after drying. The negative electrode is high-purity zinc foil, which is soaked in absolute ethanol for 1 to 2 hours, and cut into sheets of appropriate size as the negative electrode. With a concentration of 3mol / L ZnSO 4 The aqueous solution is the electrolyte. The separator is glass fiber filter paper, and finally the prepared positive electrode, negative electrode, separator and electrolyte are assembled into an aqueous zinc-ion battery...

Embodiment 3

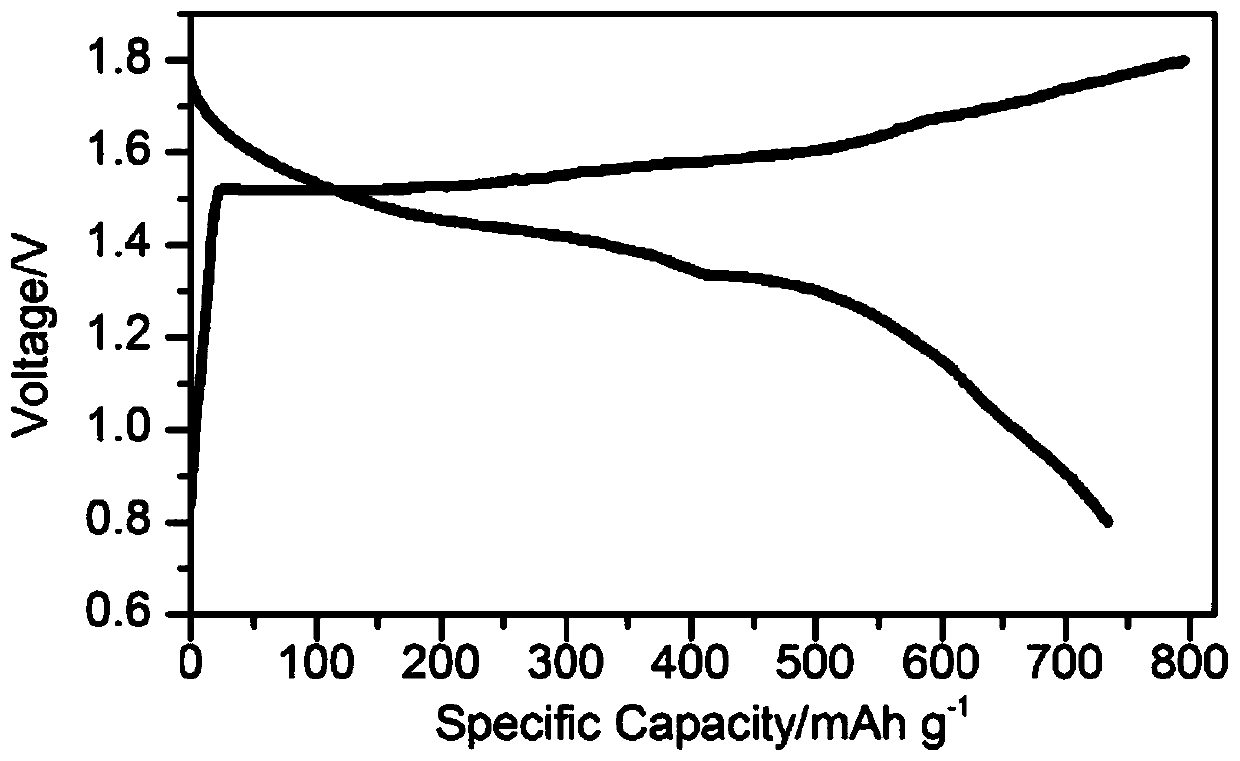

[0035] Nano-sulfur is used as the positive active material, and the positive plate is assembled according to the ratio of nano-sulfur: acetylene black: polyvinylidene fluoride with a mass ratio of 7:2:1, and is evenly mixed, and ground until a uniformly mixed slightly fluid paste slurry is formed. , and then evenly spread the paste slurry on a stainless steel foil of appropriate size, and finally dry it at 60°C for 18 hours, then cut it into a sheet of appropriate size as the positive electrode of the battery. The negative electrode is high-purity zinc foil, which is soaked in absolute ethanol for 1 to 2 hours, and cut into sheets of appropriate size as the negative electrode. With a concentration of 3mol / L ZnSO 4 The aqueous solution is the electrolyte. The diaphragm is ordinary filter paper, and finally the prepared positive electrode, negative electrode, diaphragm and electrolyte are assembled into a water-based zinc-ion battery. 24 hours after the battery is installed, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com