A kind of high-efficiency pretreatment of fibrous biomass to separate hemicellulose and its comprehensive utilization method

A technology of hemicellulose and pretreatment, applied in lignin derivatives, chemical instruments and methods, pulping with organic solvents, etc. problems, to achieve the effects of excellent thermal stability and chemical stability, strong process operability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

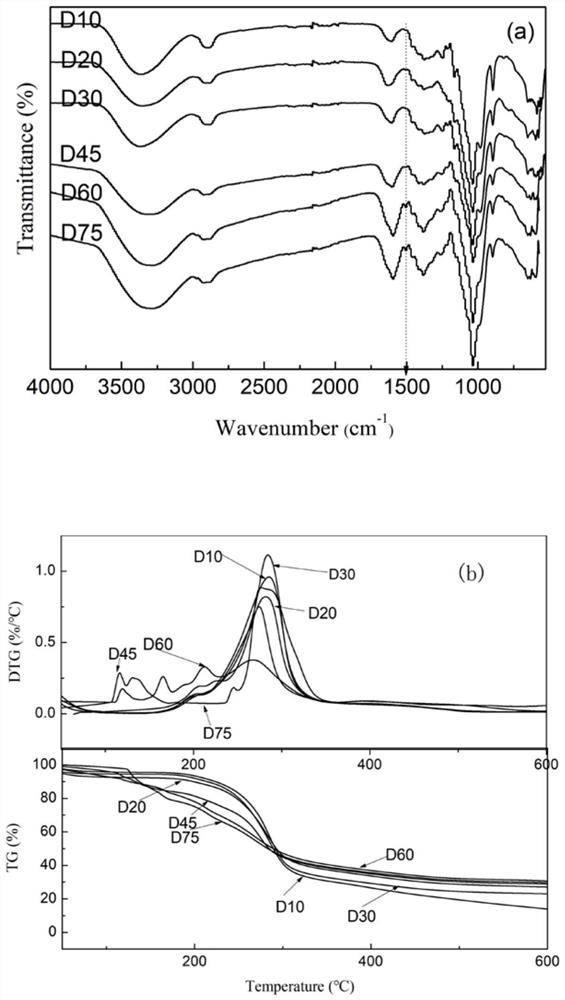

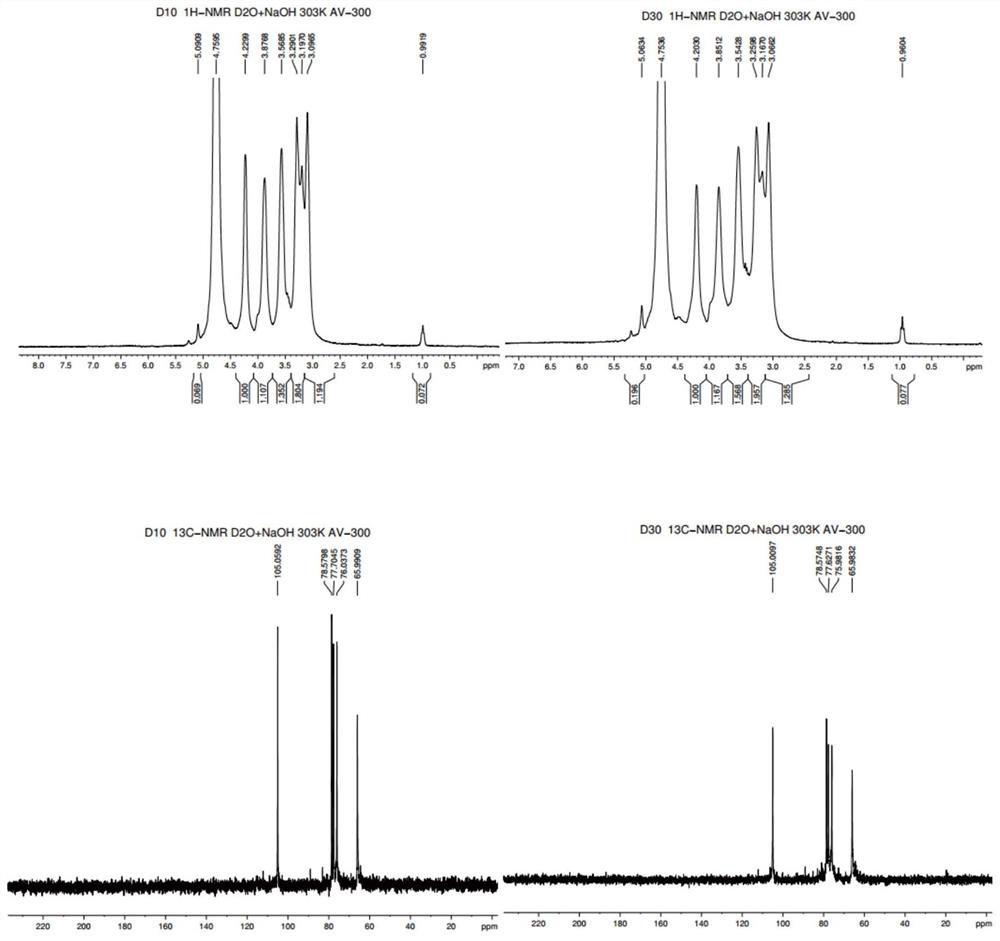

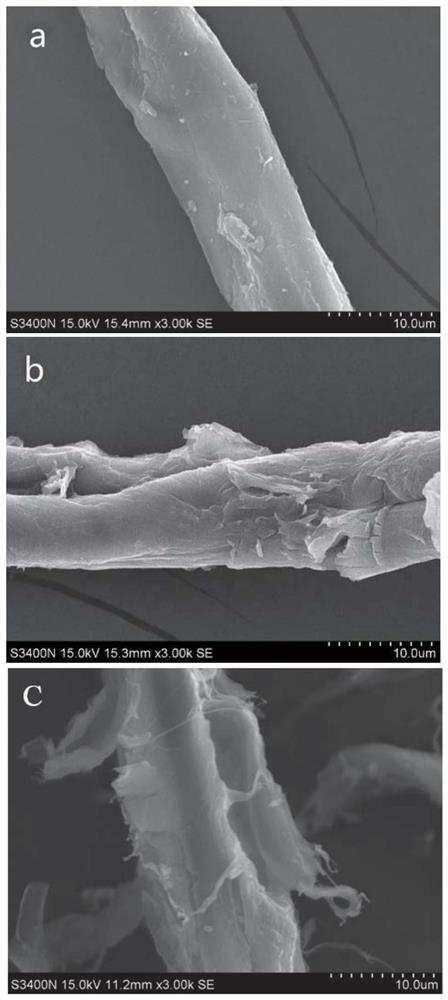

Method used

Image

Examples

Embodiment 1

[0053] The first step: slurry state method pre-treatment: 10g of mulberry tree harvesting and processing residues (cellulose content 3.7g, hemicellulose content 4.3g, lignin content 1.7g, moisture 0.1g, ash content 0.2g) were pulverized by a ball mill Sieve (180 mesh), mix the obtained mulberry powder with quantitative water (mass ratio 1:10), add it into the pre-mixing kettle, stir at room temperature for 60min, and then transfer to the pressurized reaction kettle.

[0054] The second step: hydrothermal pretreatment: add a certain amount of water to the premixed solution (mass ratio 1:20), gradually raise the temperature to 180°C for 60 minutes under stirring, then cool to room temperature, and filter.

[0055] The third step: gradient sedimentation and separation: at room temperature, add 10% absolute ethanol to the filtrate obtained in the second step, after centrifugation and separation, filter, wash the filter cake with ethanol, and store it in vacuum freeze-drying. Repea...

Embodiment 2

[0058] The first step: slurry state method pre-treatment: 10g of mulberry tree harvesting and processing residues (cellulose content 3.7g, hemicellulose content 4.3g, lignin content 1.7g, moisture 0.1g, ash content 0.2g) were pulverized by a ball mill Sieve (40 mesh), the obtained mulberry powder is mixed with quantitative water (mass ratio 1:5) and added to the pre-mixing kettle, stirred at room temperature for 10 minutes, and then transferred to the pressurized reaction kettle.

[0059] The second step: hydrothermal pretreatment: add a certain amount of water to the premixed liquid (mass ratio 1:10), gradually raise the temperature to 160° C. for 120 minutes with stirring, then cool to room temperature, and filter.

[0060]The third step: gradient sedimentation and separation: at room temperature, add 10% absolute ethanol to the filtrate obtained in the second step, after centrifugation and separation, filter, wash the filter cake with ethanol, and store it in vacuum freeze-d...

Embodiment 3

[0063] The first step: slurry state method pre-treatment: 10g of mulberry tree harvesting and processing residues (cellulose content 3.7g, hemicellulose content 4.3g, lignin content 1.7g, moisture 0.1g, ash content 0.2g) were pulverized by a ball mill Sieve (120 mesh), mix the obtained mulberry powder with quantitative water (mass ratio 1:7), add it to the pre-mixing kettle, stir at room temperature for 30 minutes, and then transfer to the pressurized reaction kettle.

[0064] The second step: hydrothermal pretreatment: add a certain amount of water to the premix (mass ratio 1:15), gradually raise the temperature to 220° C. for 20 minutes with stirring, cool to room temperature, and filter.

[0065] The third step: gradient sedimentation and separation: at room temperature, add 10% absolute ethanol to the filtrate obtained in the second step, after centrifugation and separation, filter, wash the filter cake with ethanol, and store it in vacuum freeze-drying. Repeat the above o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com