Leaf surface nanometer light conversion technology for promoting plant photosynthesis

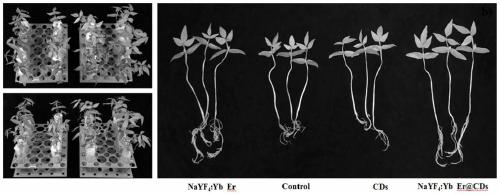

A photosynthesis and leaf technology, applied in the directions of plant growth regulators, plant growth regulators, botanical equipment and methods, etc., to achieve strong bioluminescence imaging effects, promote the growth of bean sprouts, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: NaYF 4 : Preparation of Yb,Er nanoparticles

[0031] A. Mix oleic acid (20ml), sodium hydroxide (1.16g), absolute ethanol (7ml), and deionized water (9ml) evenly, and add 7ml of YCl under vigorous stirring. 3 , YbCl 3 , ErCl 3 Aqueous solution (wherein YCl 3 , YbCl 3 , ErCl 3 A total of 1 mmol, the molar ratio of the three is 39:10:1) and NaF (5 mmol), heated to boiling and reflux, and stirred for 6 hours to obtain a mixture.

[0032] B. Transfer the mixture to a 50mL stainless steel autoclave, and conduct hydrothermal treatment at 190°C for 24h. After the sample was naturally cooled to room temperature, absolute ethanol (20 mL) was added to reflux the mixture and centrifuged three times, and finally dried under vacuum at 60 ° C for 6 h to obtain NaYF 4 : Yb,Er UCNPs.

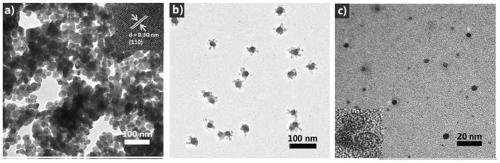

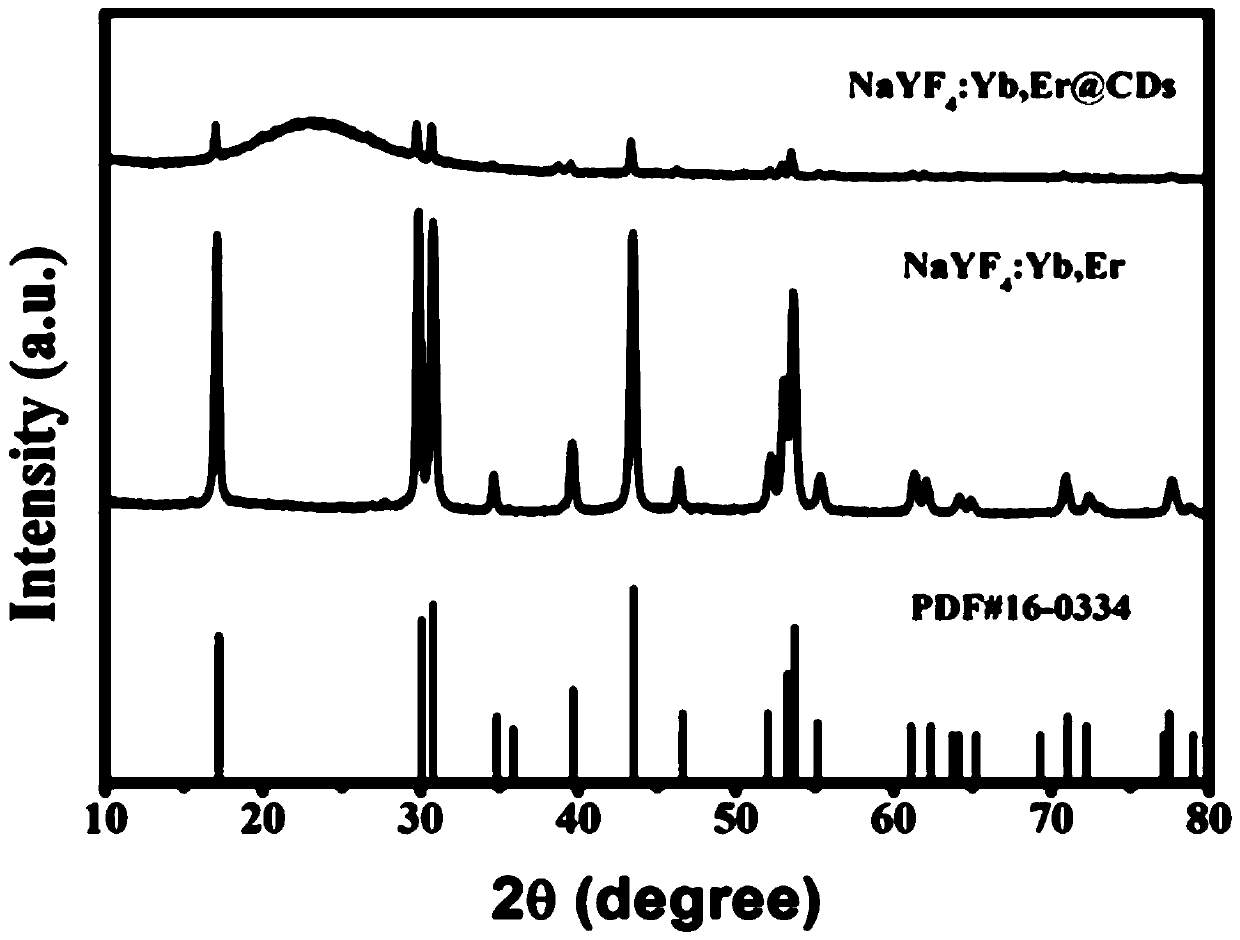

[0033] figure 1In a) is the NaYF that embodiment 1 obtains 4 : Transmission electron microscope image of Yb, Er nanoparticles, it can be seen from the figure that the prepared nanopa...

Embodiment 2

[0034] Embodiment 2: Preparation of carbon dots

[0035] C. Add 3mmol citric acid and 10mmol thiourea to 10ml acetone, mix and pour into a 30mL stainless steel autoclave, hydrothermally treat at 160°C for 8h, then centrifuge at 15000r / min for 5 minutes; wash with petroleum ether and ethyl acetate The supernatant was centrifuged at 15000r / min for 5 minutes. The final product was dissolved in 20 mL of ethanol to obtain a carbon dot solution (CDs solution).

[0036] figure 1 b in Example 2 is the transmission electron microscope image of the carbon dots obtained in Example 2. From the figure, we can see that the prepared carbon dots are evenly distributed. The illustration is the lattice structure of the carbon dots. From the figure, we can see that the lattice structure is obvious , the lattice fringe spacing is 0.24nm, which conforms to the (100) carbon graphene crystal plane.

Embodiment 3

[0037] Example 3: NaYF 4 : Preparation of Yb, Er / carbon dot nanocomposite luminescent material

[0038] D, get 4mL silica sol (with TEOS, EtOH, H 2 O and hydrochloric acid with a pH value of 2 were mixed according to the molar ratio of 1:4:5:0.2, refluxed at a temperature of 100°C for 90 minutes, and the final pH value was adjusted to 2 to obtain a silica sol), and 0.1 g of NaYF obtained in Example 1 was added 4 : Yb, Er UCNPs, then 1ml of the CDs solution obtained in Example 2 was poured into the mixed solution; the mixed system continued to stir until a uniform gel was formed. The resulting gel was vacuum dried at 60°C for 6 hours, and finally the dried product was ground into uniform particles, namely NaYF 4 : Yb, Er / carbon dot nanocomposite luminescent material.

[0039] figure 1 C in the NaYF that embodiment 3 obtains 4 : Transmission electron microscope image of Yb, Er / carbon dot nanocomposite luminescent material. From the figure we can see that the prepared NaYF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com