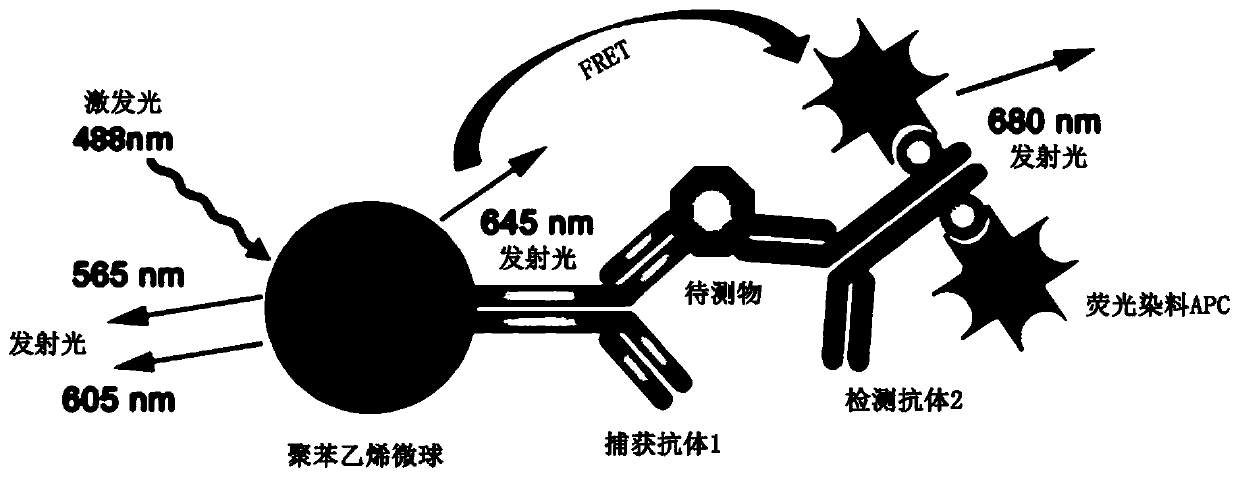

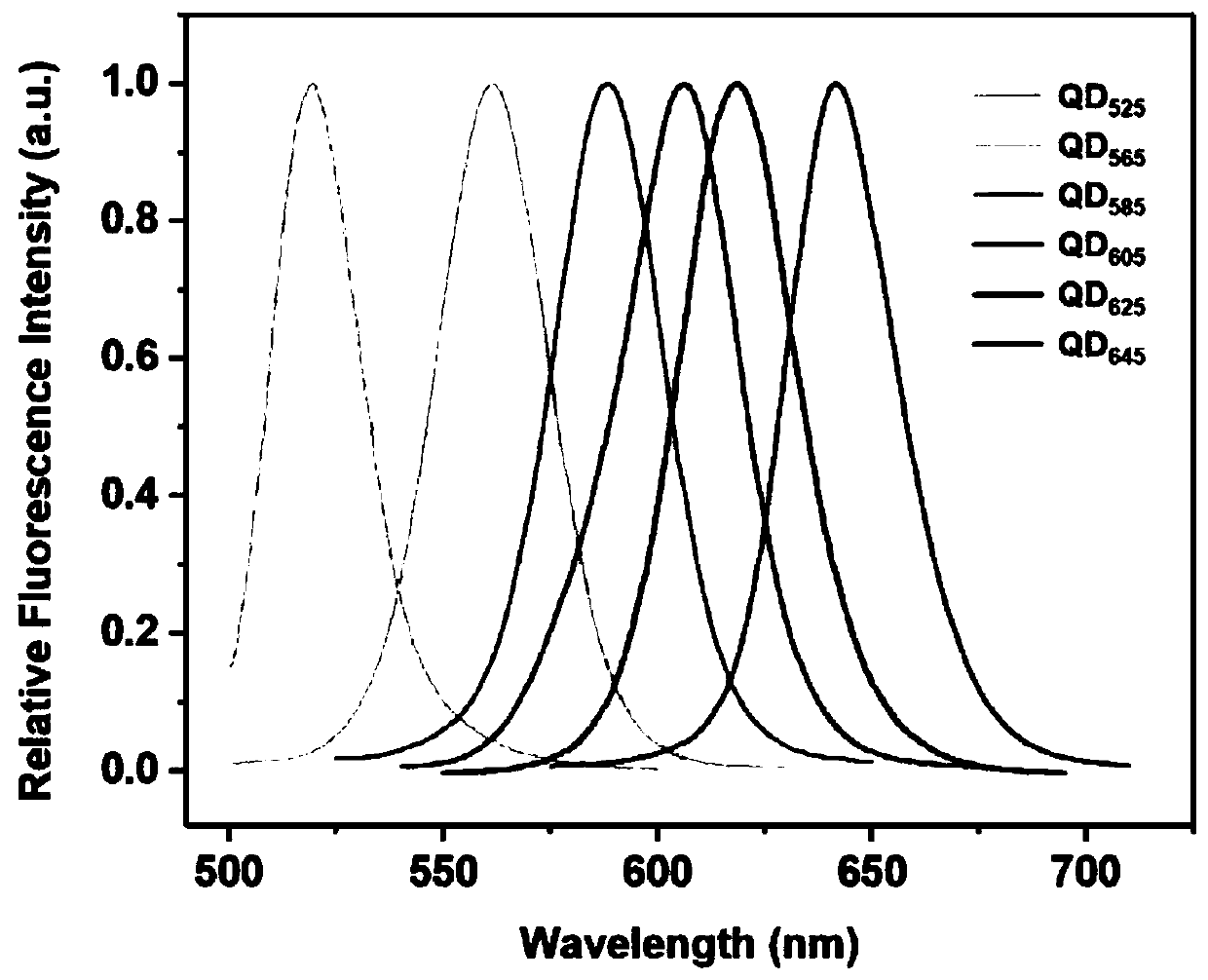

Quantum-dot fluorescent encoded microspheres based on fluorescence resonance energy transfer analysis and preparation method thereof

A fluorescence resonance energy and fluorescence encoding technology, applied in the field of multi-component biomarker analysis, can solve the problems of false positives, easy to be photobleached, strong mutual interference, etc., and achieve the effect of ensuring stability and good fluorescence stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] Specific embodiment one: the preparation of amino-modified quantum dot coded microspheres comprises the following steps:

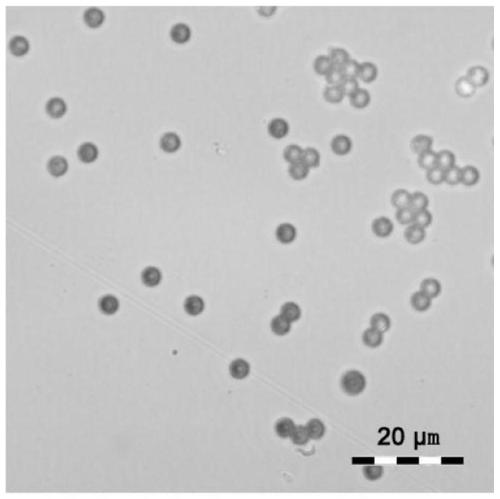

[0034] S1: Preparation of polystyrene microspheres: Mix 2 mL of styrene monomer, 0.2 mL of divinylbenzene, and 40-60 mg of AIBN, and then add them to the dispersion medium polyethylene 3-5% polyvinyl alcohol solution, at 70 ° C In a constant temperature four-neck flask, react for 8 h under the condition of blowing nitrogen and stirring (stirring speed is 100 r / min). The product was precipitated by centrifugation, washed three times with ethanol and water respectively, and dried in vacuum to obtain polystyrene microspheres. It looks like image 3 It can be seen from the figure that its morphology is spherical, the particle size distribution is narrow, and it is a uniform monodisperse sphere.

[0035]S2: Amination modification of polystyrene microspheres: 1 g of polystyrene microspheres was weighed and dispersed in 10 mL of deionized water to prepar...

specific Embodiment 2

[0038] Specific embodiment two: the preparation of the quantum dot coded microsphere of carboxyl modification comprises the following steps:

[0039] S1: Preparation of polystyrene microspheres: Mix 2 mL of styrene monomer, 0.2 mL of divinylbenzene, and 40-60 mg of AIBN, and then add them to the dispersion medium polyethylene 3-5% polyvinyl alcohol solution. In a four-neck flask with a constant temperature of ℃, react for 8 h under the conditions of blowing nitrogen and stirring (stirring speed is 100 r / min). The product was precipitated by centrifugation, washed three times with ethanol and water respectively, and dried in vacuum to obtain polystyrene microspheres.

[0040] S2: Carboxylation modification of polystyrene microspheres: Weigh 1g of polystyrene microspheres, 25mg of sodium lauryl sulfate, 250mg of potassium persulfate, add 40mL of distilled water and ultrasonically mix evenly; take another 15mL centrifuge tube, Add 4mL methanol, then add 980μL undecylenic acid an...

specific Embodiment 3

[0043] Specific embodiment three: the preparation of the aldehyde-modified quantum dot coded microsphere comprises the following steps:

[0044] S1: Preparation of polystyrene microspheres: Mix 2 mL of styrene monomer, 0.2 mL of divinylbenzene, and 40-60 mg of AIBN, and then add them to the dispersion medium polyethylene 3-5% polyvinyl alcohol solution. In a four-neck flask with a constant temperature of ℃, react for 8 h under the conditions of blowing nitrogen and stirring (stirring speed is 100 r / min). The product was precipitated by centrifugation, washed three times with ethanol and water respectively, and dried in vacuum to obtain polystyrene microspheres.

[0045] S2: Aldehyde modification of polystyrene microspheres: In a 250mL four-neck flask equipped with a stirrer, add 3g polystyrene microspheres and 30mL dichloromethane to fully swell the microspheres for 12h, then add 13mL 1 , 4-dichloromethoxybutane and 1.5mL of tin tetrachloride were reacted at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com