Alcohol dehydrogenase and application thereof in preparing alcohol

An alcohol dehydrogenase and purpose technology, applied in the field of genetic engineering, can solve the problems of the difficulty of alcohol dehydrogenase, the high investment cost of production equipment, the slow speed of forward movement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the preparation method of the above recombinant alcohol dehydrogenase, the expression host cell is Escherichia coli.

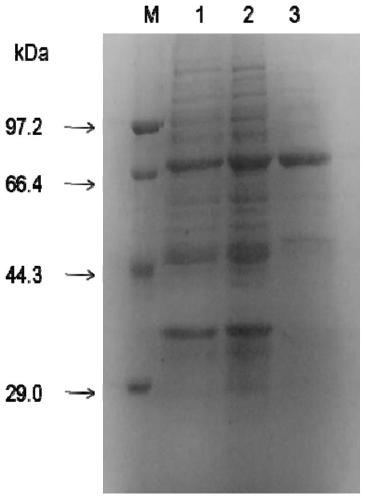

[0042]The preparation method of the above-mentioned recombinant alcohol dehydrogenase enzyme, the specific process is as follows: including double digestion with BamHI and HindIII to obtain the target gene and connecting the pET-32a(+) vector, transforming it into Escherichia coli BL21(DE3), inducing with IPTG, Efficient soluble expression was obtained.

[0043] The final concentration of IPTG is 0.6-1.8mM, and the induction temperature is 18-37°C.

[0044] The recombinant alcohol dehydrogenase provided by the invention comprises the method and steps of transforming the expression host cell with the above-mentioned expression vector, culturing the transformant, and obtaining the recombinant alcohol dehydrogenase from the culture.

[0045] The last object of the present invention is achieved through the following technical scheme: the application of ...

Embodiment 1

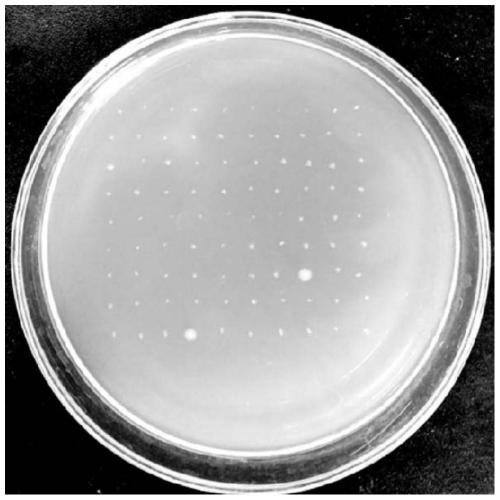

[0054] Example 1 Establishment of metagenomic library and acquisition of positive clones, gene cloning and expression

[0055] 1. Extraction of total DNA:

[0056] Weigh 5g sample, the sample is the soil near the biomass acid hydrolysis equipment, add 13.5ml DNA extraction buffer (0.1M Tris, 0.1M EDTA-Na, 0.1M Na 3 PO 4 , 1.5M NaCl, 1% CTAB, pH 8.0), shake vigorously, add 300μl lysozyme (100mg / ml), invert 5-6 times, 37℃ water bath for 30min, add 1.5ml 20% SDS, 65℃ Water bath for 1h (during this period, turn it upside down several times every 15min), centrifuge at 8000r / min for 5min, take the supernatant, extract twice with an equal volume of chloroform, centrifuge at 8000r / min for 10min, take the supernatant, add 0.6 times the volume of isopropyl Alcohol, place at room temperature for 2h, centrifuge at 20000r / min for 20min, discard the supernatant, add 5mL of pre-cooled 70% ethanol to the pellet, centrifuge at 20000r / min for 10min, collect the DNA precipitate, air-dry, and d...

Embodiment 2

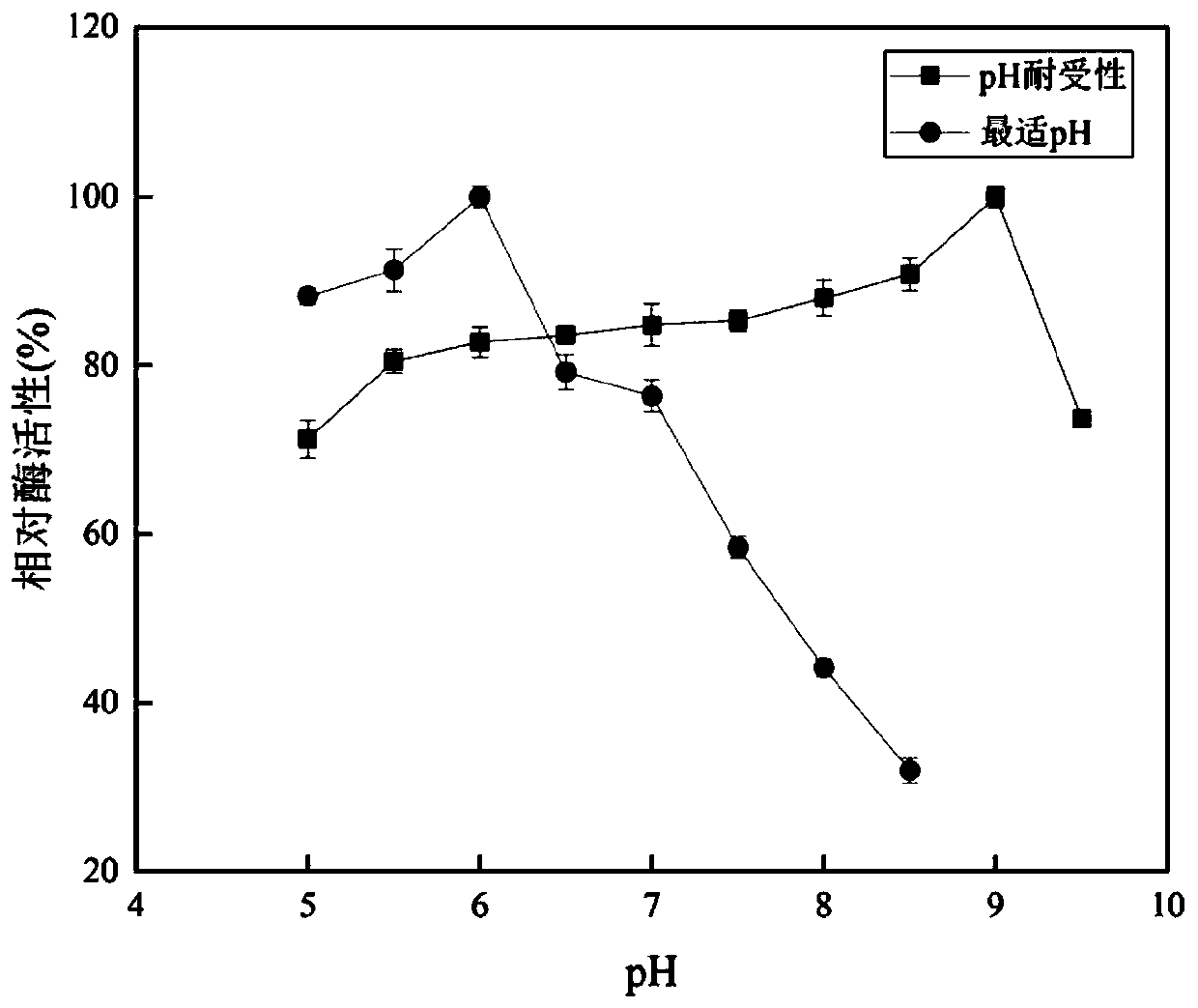

[0079] The mensuration of embodiment 2 enzyme activity

[0080] (1) Definition of alcohol dehydrogenase activity with furfural as substrate: 1 unit of alcohol dehydrogenase activity is defined as the amount of enzyme required to reduce 1 μmol of furfural per minute at pH 6.0 and 30°C.

[0081](2) Measuring principle: use furfural as a substrate to measure enzyme activity, alcohol dehydrogenase catalyzes the reduction of 1 mol of furfural to generate 1 mol of furfuryl alcohol, and at the same time oxidizes 1 mol of NADPH to generate 1 mol of NADP + , NADPH has the largest characteristic absorption peak at 340nm, within a certain range of light absorption value, the light absorption value at 340nm is proportional to the concentration of NADPH.

[0082] (3) The determination method is as follows:

[0083] Reaction system: 300 μl, including: 10 mM furfural, 0.1 mM NADPH, 50 μl diluted enzyme solution, pH 6.0 potassium phosphate buffer. In a microplate reader, detect the light ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com