Treatment method of titanium mineral and metal silicate mineral through ammonium salt pressurized pyrolysis

A metal silicate and titanium mineral technology, applied in chemical instruments and methods, titanium compounds, titanium oxide/hydroxide, etc., can solve the problems of low product purity, low titanium magnesium aluminum leaching rate, and low product purity. , to achieve the effects of environmental friendliness, improved resource utilization, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

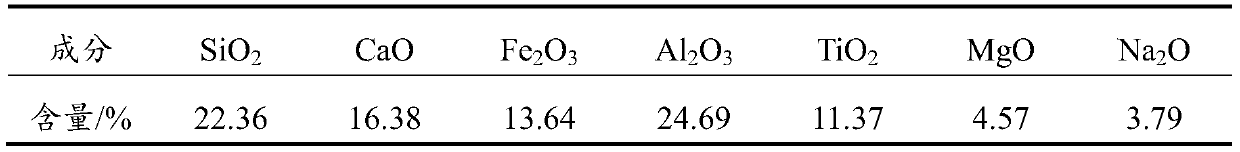

[0048] The chemical composition analysis of steel slag from Ningshan Iron and Steel Group is as follows:

[0049] Table 1 Analysis results of steel slag composition

[0050]

[0051] The sample was taken from the steel slag of the oxygen-blown top converter of Ningshan Iron and Steel Group. The chemical composition analysis results are shown in Table 1. The main minerals are grossular garnet and cabernetite.

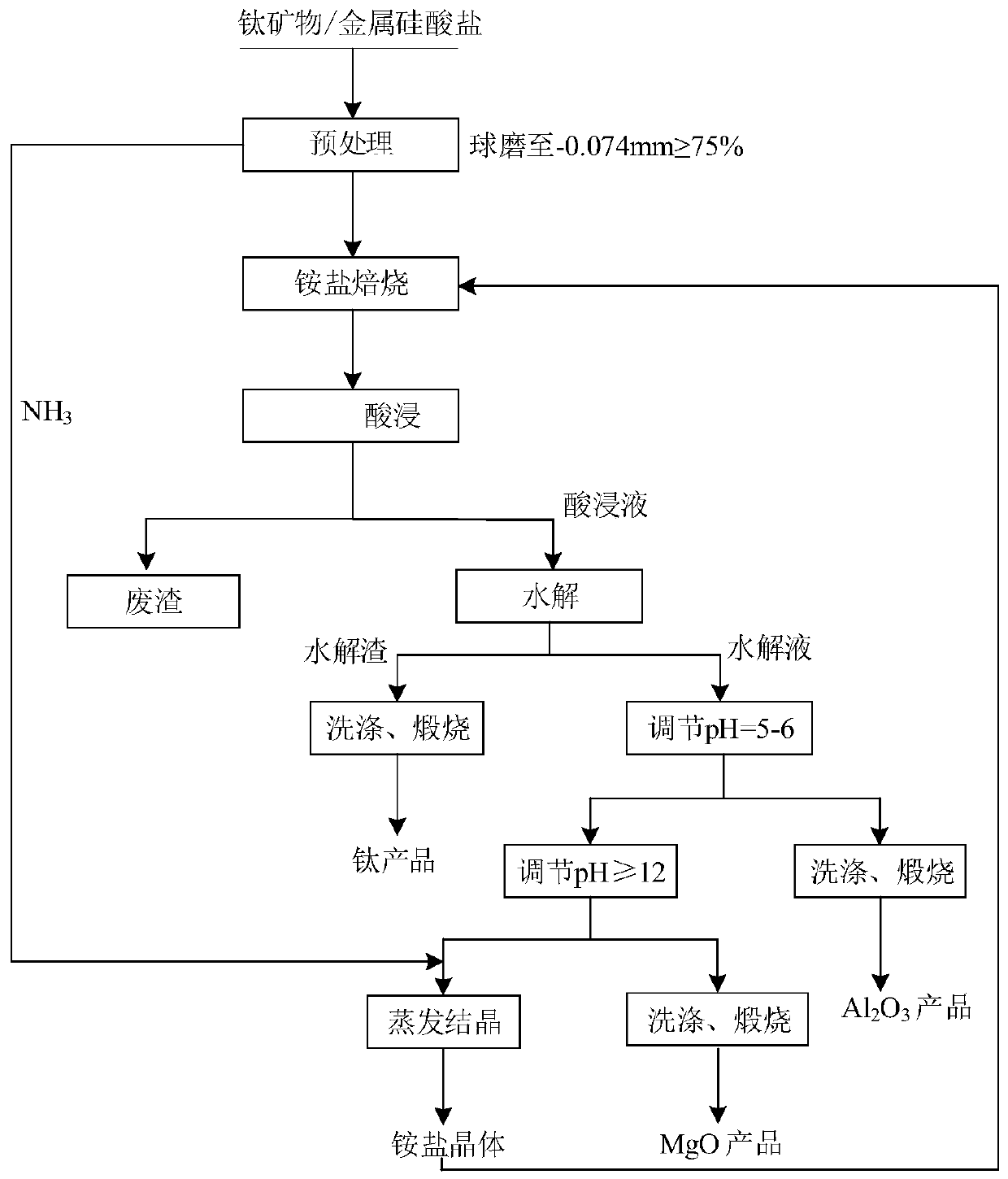

[0052] according to figure 1 The method carries out cascade recovery titanium magnesium aluminum valuable metal, and concrete steps are as follows:

[0053] (1) Ammonium sulfate roasting

[0054] Ball mill the steel slag to -0.074mm to 81.09%, dry and disperse at 90°C, mix the above powder material with ammonium sulfate at a ratio of 1:3, and pyrolyze it in an autoclave at a temperature of 300°C for 1.5 h, the sampling port is opened at the initial stage, the generated ammonia gas is collected, and distilled water is introduced to form ammonia water, and when the g...

Embodiment 2

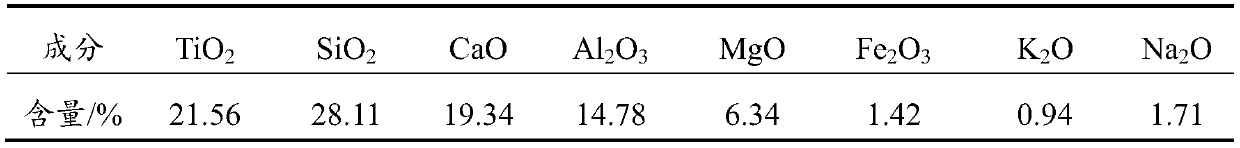

[0060] The chemical composition analysis of the titanium-containing blast furnace slag of Panzhihua Iron and Steel Group is as follows:

[0061] Table 2 Component analysis results of titanium-containing blast furnace slag

[0062]

[0063] The samples were taken from the titanium-containing blast furnace slag after ironmaking in Panzhihua Iron and Steel Group. The chemical composition analysis results are shown in Table 2. The main minerals are perovskite and diopside.

[0064] according to figure 1 The method carries out cascade recovery titanium magnesium aluminum valuable metal, and concrete steps are as follows:

[0065] (1) Ammonium sulfate roasting

[0066] Ball mill the titanium-containing blast furnace slag to -0.074mm to 77.28%, dry and break up at 95°C, mix the above powder material with ammonium sulfate at a ratio of 1:2, and put it in an autoclave at a temperature of 350°C After pyrolysis for 2 hours, the sampling port is opened at the initial stage, the gene...

Embodiment 3

[0072] The chemical composition analysis of the high-titanium slag of Hesteel Co., Ltd. is as follows:

[0073] Table 3 Analysis results of high titanium slag components

[0074]

[0075] The sample was taken from the high-titanium slag smelted in the electric furnace of HBIS Co., Ltd. The chemical composition analysis results are shown in Table 3. The main minerals are black titanite, silicate glass body and free TiO 2 .

[0076] according to figure 1 The method carries out cascade recovery titanium magnesium aluminum valuable metal, and concrete steps are as follows:

[0077] (1) Ammonium sulfate roasting

[0078] Ball mill the high-titanium slag to -0.074mm to 71.63%, dry and break up at 100°C, mix the above powder material with ammonium sulfate at a ratio of 1:4, and heat it in an autoclave at a temperature of 400°C After 2.5 hours of solution, the sampling port is opened at the initial stage, the generated ammonia gas is collected, and distilled water is passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com