A kind of polymer powder surface treatment method

A processing method and polymer technology, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problem of no regulation of surface characteristics, and achieve the effect of improving application effect, simple and general method, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Dissolve 30g β-cyclodextrin in 600ml deionized water, add 18g NaOH solution (0.75mol / L), stir under ice bath for 30min, add 6g p-toluenesulfonyl chloride in batches, keep stirring at 0-5°C After reaction for 5h, suction filtration to obtain pale yellow clear solution, adjust pH to 6-7 with 2mol / L hydrochloric acid, white precipitate is precipitated, refrigerate overnight, suction filter and recrystallize twice, and dry to obtain 6-OTs-β-CD.

[0058] Take 0.83g potassium carbonate and 2ml ethylenediamine in a 100ml three-necked round bottom flask, add 15ml DMF as a solvent, stir at room temperature for 2h, add 7.8g of 6-OTs-β-CD dissolved in 15ml DMF, heat up to 80°C, The reaction was stirred under nitrogen protection for 24h. After cooling, the reaction solution was poured into 200 ml of acetone for precipitation, and after suction filtration and drying, light yellow solid ethylenediamine-β-cyclodextrin was obtained.

Embodiment 2

[0062] 100 parts by mass of aqueous medium (1wt% methanol aqueous solution), 0.4 parts by mass of polyvinylpyrrolidone with a number-average molecular weight of 150,000 g / mol, and 0.01 parts by mass of defoamer BYK-019 were heated and mixed uniformly at 90°C to obtain a treated solution;

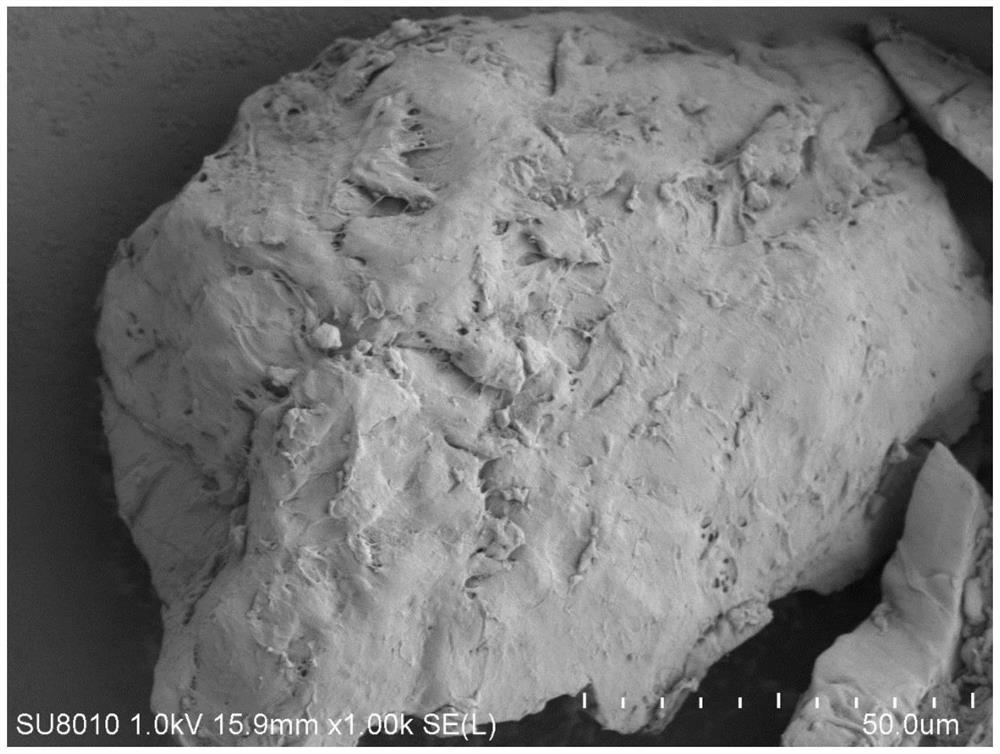

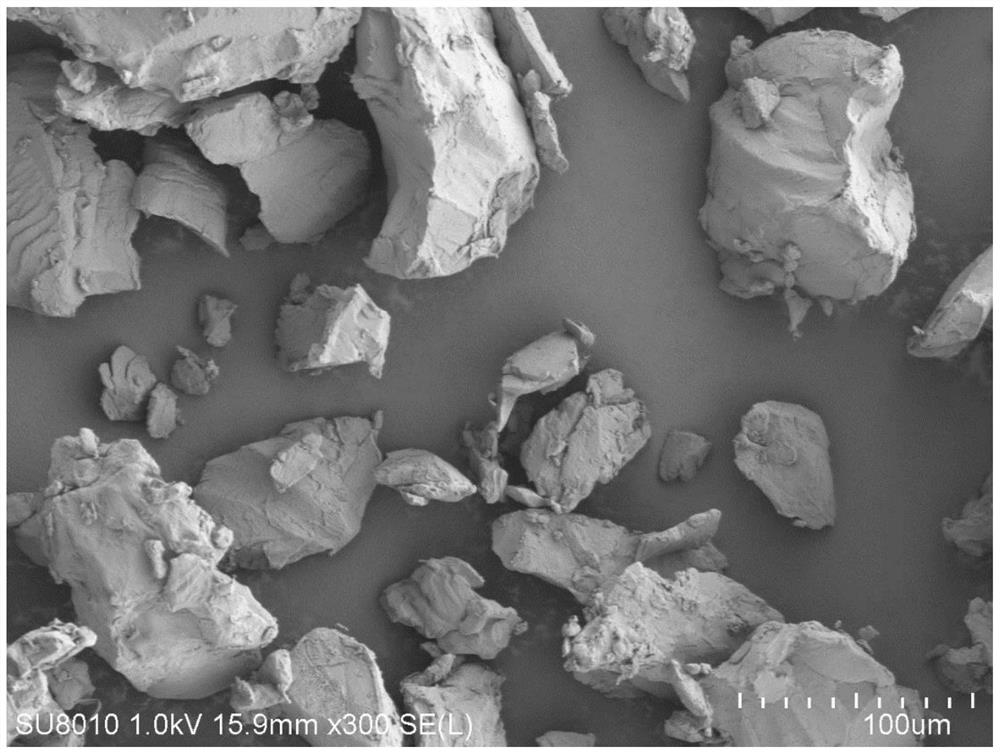

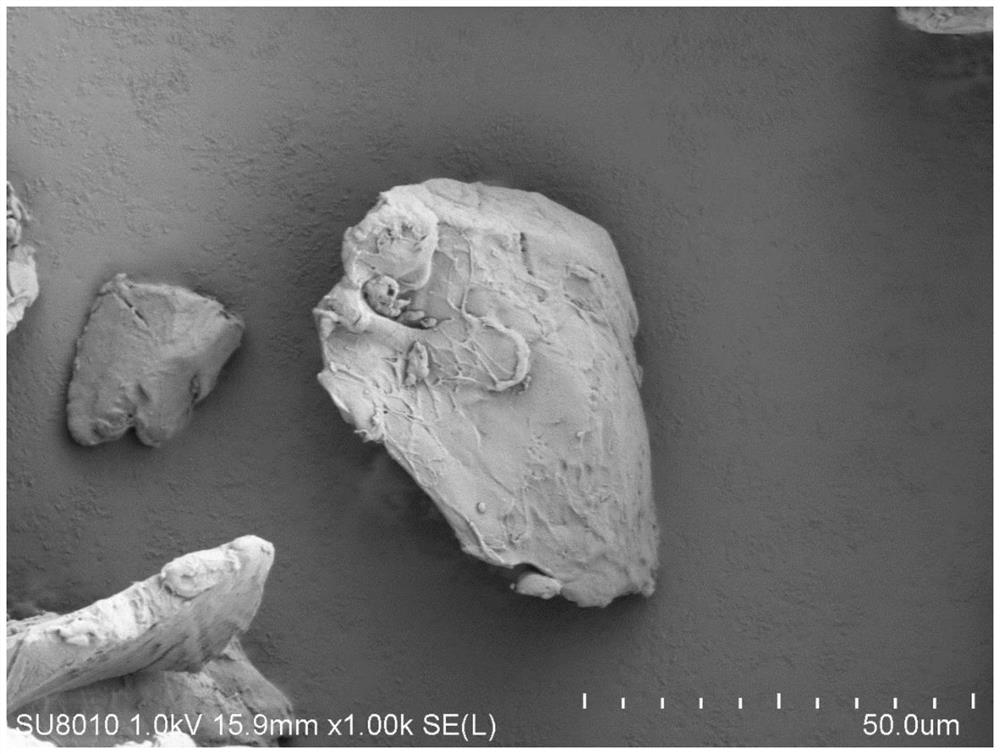

[0063] 2 parts by mass of D 50 = 300 μm thermoplastic polyurethane powder was mixed with the aforementioned treatment solution, and mixed at 35° C. for 10 minutes. After solid-liquid separation by centrifugation, vacuum-dried at 60° C. for 4.5 hours to obtain polymer microsphere powder.

Embodiment 3

[0065] 100 mass parts of aqueous medium (8wt% ethanol aqueous solution), 5 mass parts of hydroxyethyl cellulose (number average molecular weight 20000g / mol, the viscosity of its 2wt% aqueous solution is 50mPa.s), 0.1 mass parts defoamer BYK-024 was heated and mixed evenly at 60°C to obtain a treatment solution;

[0066] 50 parts by mass of D 50 = 10 μm thermoplastic polyurethane powder was mixed with the aforementioned treatment solution, and mixed at 50 °C for 60 min. After solid-liquid separation using a screen, it was dried under normal pressure at 90 °C for 2 hours to obtain polymer microsphere powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com