A kind of porous hollow carbon material supporting metal phosphide, its preparation and application

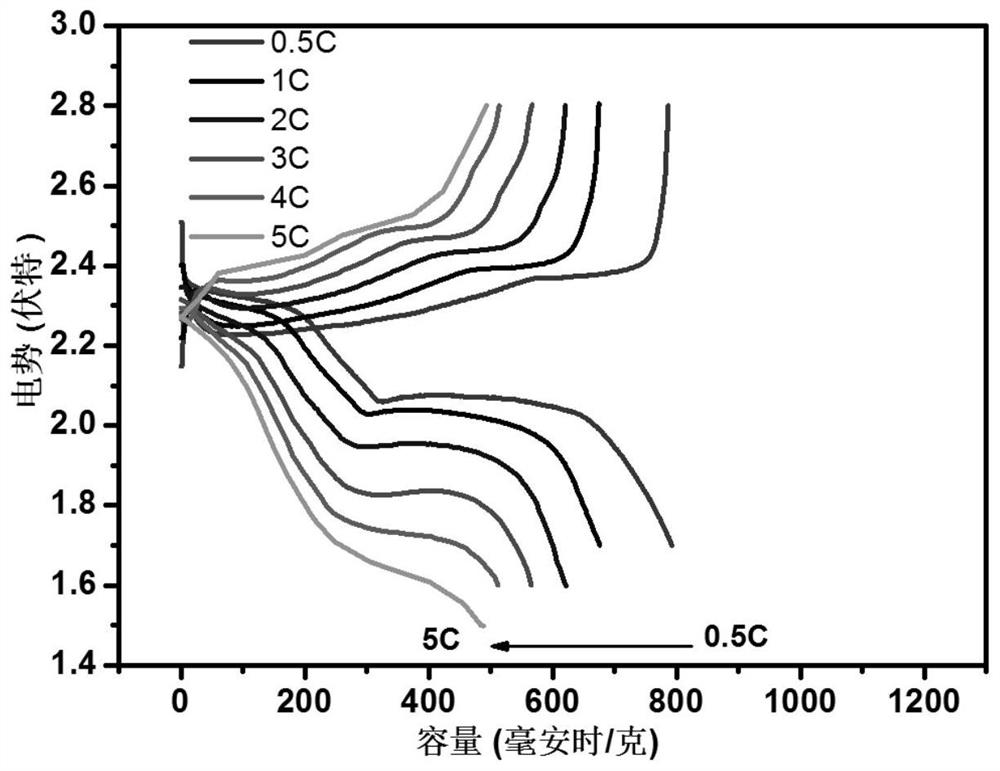

A technology of loading metals and phosphides, which is applied in the direction of active material electrodes, positive electrodes, structural parts, etc., can solve the problems of poor rate and cycle performance, low capacity, poor conductivity, etc., and achieve long-term cycle stability and specificity. The effect of high surface area and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing a porous hollow carbon material loaded with metal phosphides, comprising the following steps:

[0045] (1) A dispersion liquid of a carbon material precursor is prepared by a template method, and the carbon material precursor is a carbon material precursor coated with silica microspheres;

[0046] (2) mixing the dispersion of the carbon material precursor obtained in step (1) with the metal salt and the phosphorus source, after evaporating water and grinding, in an inert atmosphere, heat treatment to reduce the phosphorus source during the heat treatment, and combining with the metal in the metal salt to obtain a metal phosphide, which is loaded on the surface of the carbon material to obtain a carbon material supporting the metal phosphide;

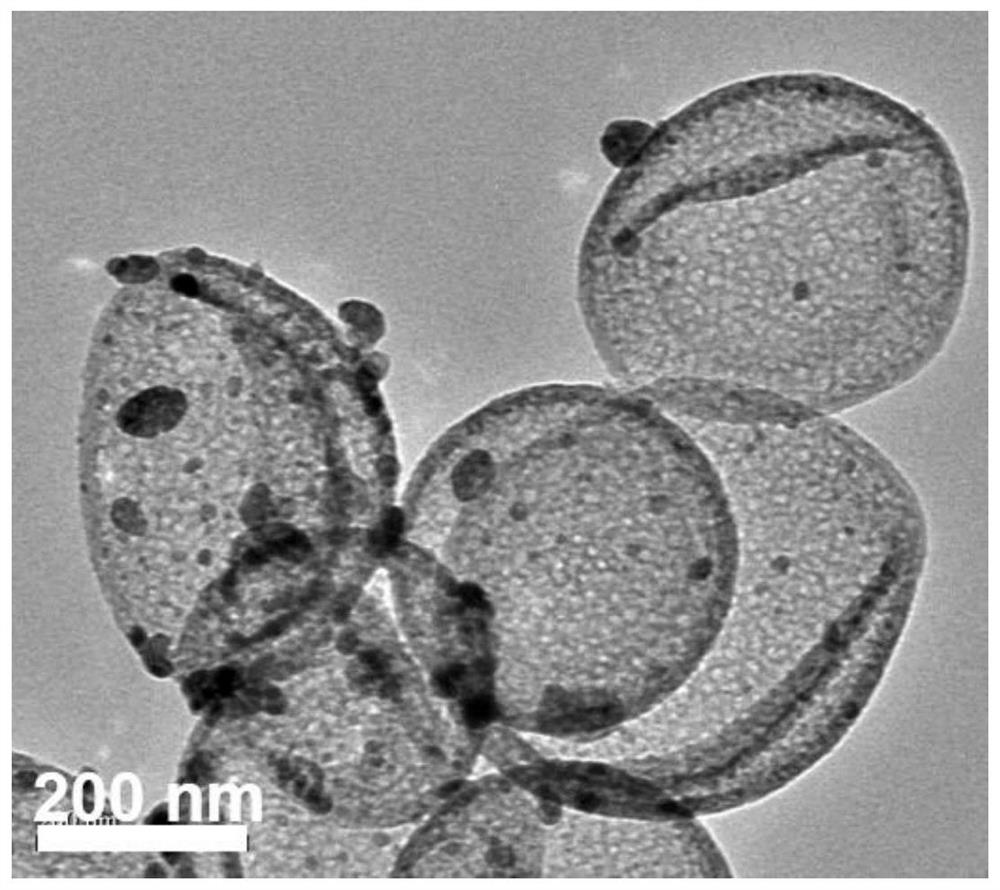

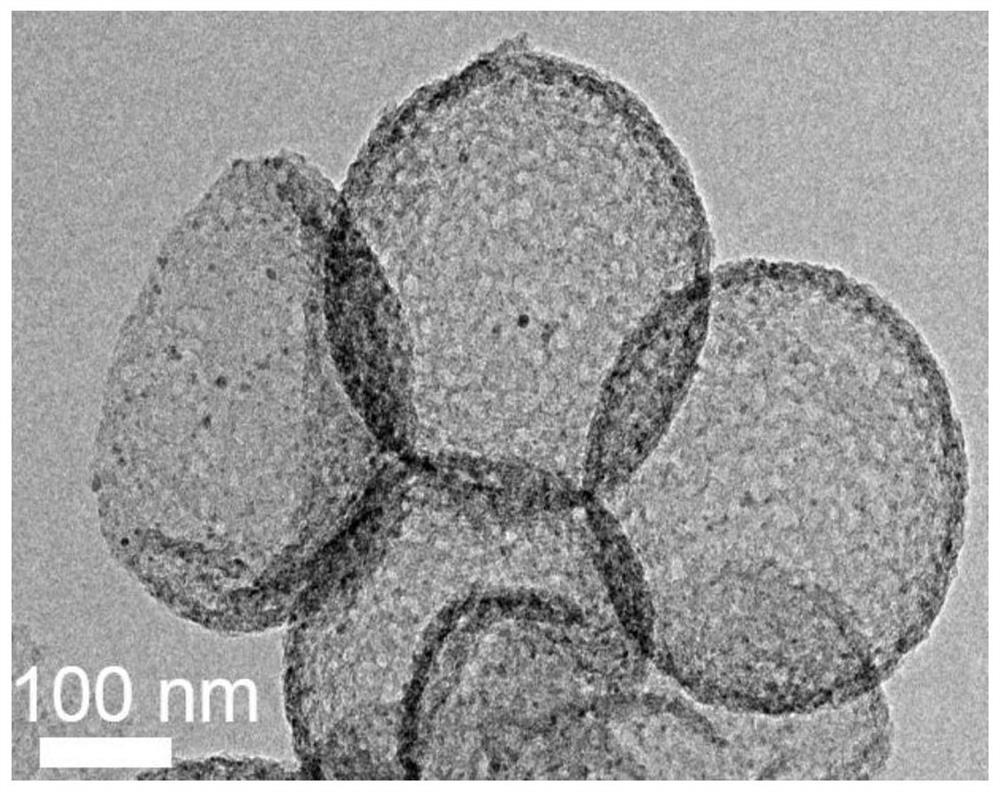

[0047] (3) Etching and removing the silicon dioxide microspheres inside the metal phosphide-loaded carbon material obtained in step (2), to obtain a metal phosphide-loaded porous hollo...

Embodiment 1

[0065] A porous hollow carbon material loaded with metal phosphides, prepared according to the following method:

[0066] (1) Take 13 milliliters of ethyl orthosilicate, dissolve it in a mixed solvent of 350 milliliters of ethanol and 50 milliliters of water, stir for 1 minute, add 10 milliliters of concentrated ammonia water (25%), continue to stir for 5 minutes, and then add 2 grams of A solution of resorcinol and 2.8 ml of formaldehyde (37%) was stirred continuously for 12 hours. After centrifugation, washing and ultrasonic dispersion in water to form a uniform dispersion.

[0067] (2) Add 0.33 millimoles of ferric chloride and 3.3 millimoles of ammonium dihydrogen phosphate to the above-mentioned dispersion liquid, and then evaporate water from the dispersion liquid at 40 degrees Celsius. The obtained solid was ground and heat-treated at 700° C. for 3 hours under an argon atmosphere.

[0068] (3) Add the heat-treated material into 0.5 mol / L sodium hydroxide solution, tre...

Embodiment 2

[0074] A porous hollow carbon material loaded with metal phosphides, prepared according to the following method:

[0075] (1) Take 13 milliliters of ethyl orthosilicate, dissolve it in a mixed solvent of 35 milliliters of ethanol and 5 milliliters of water, stir for 2 minutes, add 12.5 milliliters of concentrated ammonia water (25%), continue to stir for 10 minutes, and then add 2 grams of A solution of resorcinol and 2.8 ml of formaldehyde (37%) was stirred continuously for 18 hours. After centrifugation, washing and ultrasonic dispersion in water to form a uniform dispersion.

[0076] (2) Add 0.66 millimoles of ruthenium chloride and 3.3 millimoles of ammonium dihydrogen phosphate to the above-mentioned dispersion liquid, and then evaporate water from the dispersion liquid at 50 degrees Celsius. The obtained solid was ground and heat-treated at 800° C. for 3 hours under a nitrogen atmosphere.

[0077] (3) Add the heat-treated material into 2 mol / L sodium hydroxide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com