Biological composite slow-release fresh-keeping agent and preparation method thereof

A slow-release, antistaling agent technology, applied in the field of biological compound slow-release antistaling agents, can solve the problems of short preservation time, high cost, poor safety, etc., and achieve the goal of reducing the amount of ethylene, better inhibiting effect, and reducing ripening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

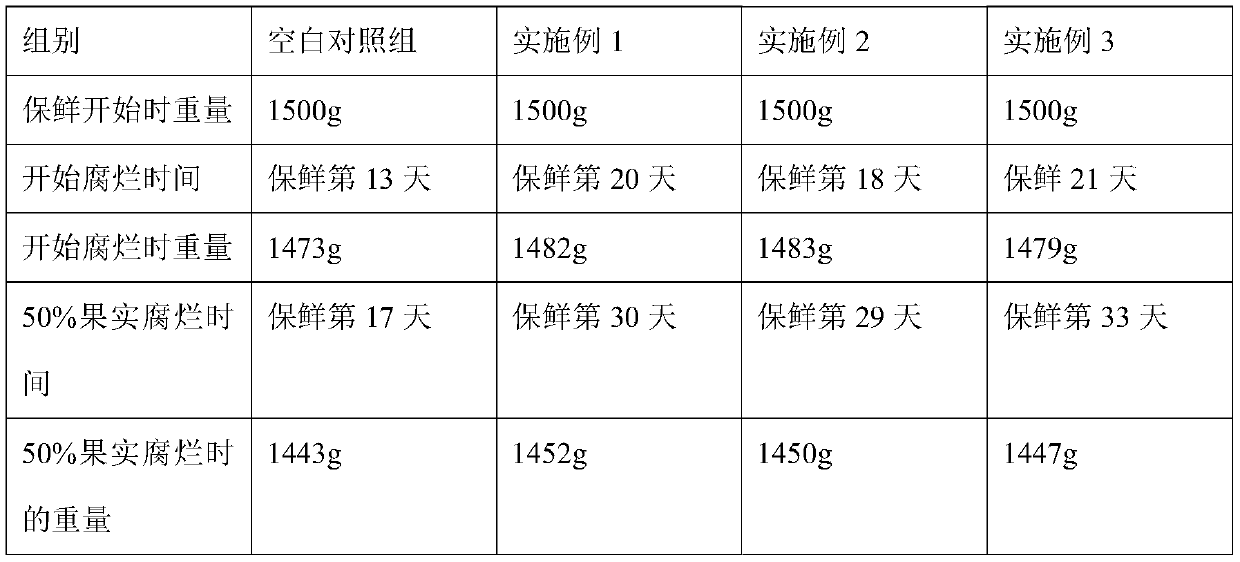

Examples

Embodiment 1

[0034] 1. Prepare an aqueous solution of camphor leaf extract: fully dry the fresh leaves in an oven at 60° C., and pulverize them with an ultrafine pulverizer. Mix 100 parts of camphor leaf powder with 400 parts of sterile water, use ultrasonic extraction at 30 °C for 1 hour, then vacuum filter, add sterile water to the filter residue according to this ratio, repeat vacuum extraction twice, and combine the filtrates.

[0035] 2. Activation of the adsorption carrier: put an appropriate amount of 4A molecular sieve in a microwave oven, heat it with high-grade firepower for 2 minutes, repeat the operation 4 times, the activation is successful, spread it out and seal it for temporary storage.

[0036] 3. Preparation of Cinnamomum camphora extract sustained-release agent: mix the aqueous solution of Cinnamomum camphora leaf extract with a mass ratio of 30:35: 4A molecular sieve, mix the two evenly, and place them in a dry and ventilated place to dry naturally to become Cinnamomum c...

Embodiment 2

[0042] Steps 1 to 4 are the same as in Example 1.

[0043] 5. Preparation of component A: Take 1.8 parts of sodium bicarbonate, 1.8 parts of anhydrous sodium carbonate, 1.8 parts of reduced iron powder, 4.5 parts of camphor slow-release agent, 4.5 parts of ethylene adsorption slow-release agent, mix well, and become component A , sealed for temporary storage.

[0044] 6. Preparation of component B: Take 0.2 parts of chlorine dioxide, 0.4 parts of diatomaceous earth, 1.2 parts of oxalic acid, and 1.4 parts of calcium chloride, mix them evenly, and put them into a breathable and water-permeable bag to become a chlorine dioxide slow-release bag. The breathable and water-permeable bag is one of virgin wood pulp paper, bamboo fiber paper, composite paper and non-woven fabric.

[0045] 7, antistaling agent finished product: step is the same as embodiment 1, promptly becomes the novel biocomposite sustained-release type antistaling agent finished product of the present invention.

Embodiment 3

[0047] Steps 1 to 4 are the same as in Example 1.

[0048] 5. Preparation of component A: Take 2.2 parts of sodium bicarbonate, 2.2 parts of anhydrous sodium carbonate, 2.2 parts of reduced iron powder, 5.5 parts of camphor slow-release agent, 5.5 parts of ethylene adsorption slow-release agent, mix well, and become component A , sealed for temporary storage.

[0049] 6. Preparation of component B: Take 0.2 parts of chlorine dioxide, 0.3 parts of diatomaceous earth, 1.2 parts of oxalic acid, and 0.8 parts of calcium chloride and mix them evenly as component B, and put them into a breathable and water-permeable bag to become chlorine dioxide slow-release Bag. The breathable and water-permeable bag is one of virgin wood pulp paper, bamboo fiber paper, composite paper and non-woven fabric.

[0050] 7, antistaling agent finished product: step is the same as embodiment 1, promptly becomes the novel biocomposite sustained-release type antistaling agent finished product of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com