Ferrite-graphene modified polycarboxyl pyrrole wave-absorbing material and preparation method thereof

A technology of graphene modification and wave-absorbing materials, which is applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problem of poor electromagnetic impedance matching performance of wave-absorbing materials, low relative complex permittivity of polypyrrole, and inability to effectively absorb electromagnetic waves and other problems, to achieve the effect of enhancing electromagnetic impedance matching performance, promoting cyclic migration, and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

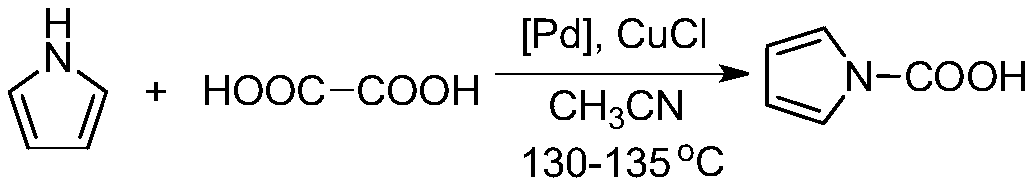

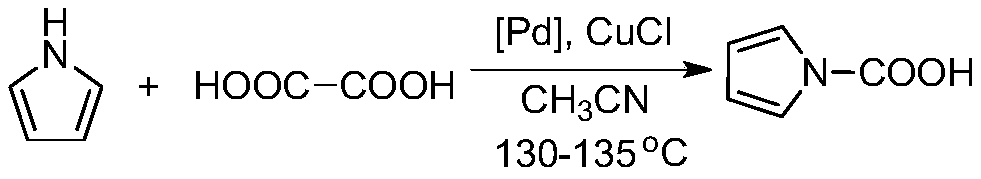

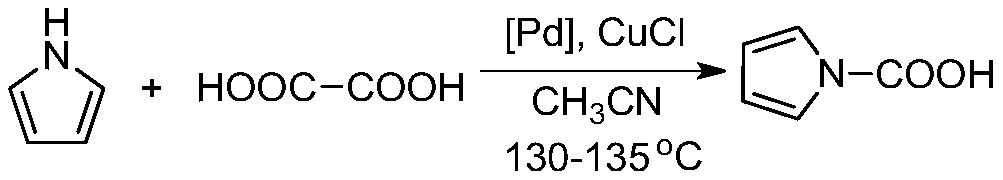

[0026] In order to achieve the above object, the present invention provides the following technical solution: a ferrite-graphene modified polycarboxypyrrole wave-absorbing material and its preparation method, including the following raw materials in parts by weight: 20-23 parts of hexahydrate three Ferric chloride, 4-6 parts of anhydrous aluminum sulfate, 5-7 parts of cobalt chloride hexahydrate, 15-17 parts of oxalic acid, 30-34 parts of pyrrole, 1-3 parts of synergistic catalyst, 10-25 parts of graphene , ferric chloride hexahydrate as FeCl 3 ·6H 2 O, where FeCl 3 The mass fraction is 56.2-58.4%, Al in anhydrous aluminum sulfate 2 (SO 4 ) 3 The mass fraction is 97.3-98.8%, cobalt chloride hexahydrate is CoCl 3 ·6H 2 O, where CoCl 3 The mass fraction is 50.6-52.2%, the simplified structural formula of oxalic acid is COOH-COOH, wherein the mass fraction of COOH-COOH is 96.8-99.2%, and the structural formula of pyrrole is Its mass fraction is 96.5-98.8%, and the synerg...

Embodiment 1

[0033] (1) Preparation of CoAl ferrite Co 0.65-0.85 Al 0.15-0.35 Fe 2 o 4 : Add 300mL of N-methylpyrrolidone and 400mL of distilled water into a 1000mL beaker, then weigh 20 parts of ferric chloride hexahydrate, 4 parts of anhydrous aluminum sulfate and 5 parts of cobalt chloride hexahydrate into the beaker, and stir the materials evenly Finally, place the beaker in an ultrasonic processor, heat it to 60-65°C, and ultrasonic frequency is 28KHz, and perform ultrasonic treatment for 4-5 hours, so that the material is evenly dispersed in the solvent to form a sol, and then the mixture in the beaker is filtered to remove the solvent , and washed with 3000-3500mL distilled water. After drying the water, place the mixed material in a tubular resistance furnace at a heating rate of 10°C / min, heat it to 750-760°C for 4-5h, and heat it to Carry out annealing for 3-4 hours. After the annealing is completed, cool the material to room temperature, and then use 500-700mL of dilute hydro...

Embodiment 2

[0039] 1) Preparation of CoAl ferrite Co 0.65-0.85 Al 0.15-0.35 Fe 2 o 4 : Add 300mL of N-methylpyrrolidone and 400mL of distilled water to a 1000mL beaker, then weigh 21 parts of ferric chloride hexahydrate, 4 parts of anhydrous aluminum sulfate and 6 parts of cobalt chloride hexahydrate in the beaker, and stir the materials evenly Finally, place the beaker in an ultrasonic processor, heat it to 60-65°C, and ultrasonic frequency is 28KHz, and perform ultrasonic treatment for 4-5 hours, so that the material is evenly dispersed in the solvent to form a sol, and then the mixture in the beaker is filtered to remove the solvent , and washed with 3000-3500mL distilled water. After drying the water, place the mixed material in a tubular resistance furnace at a heating rate of 10°C / min, heat it to 750-760°C for 4-5h, and heat it to Carry out annealing for 3-4 hours. After the annealing is completed, cool the material to room temperature, and then use 500-700mL of dilute hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com