Alkoxy oligopolyethylene phosphate metal salt and its preparation method and application

An alkoxy oligopolyethylene phosphate and metal salt technology, which can be used in chemical instruments and methods, structural parts, electrochemical generators, etc. The effect of improving charge-discharge cycle life, uniform electronic conductivity, and improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

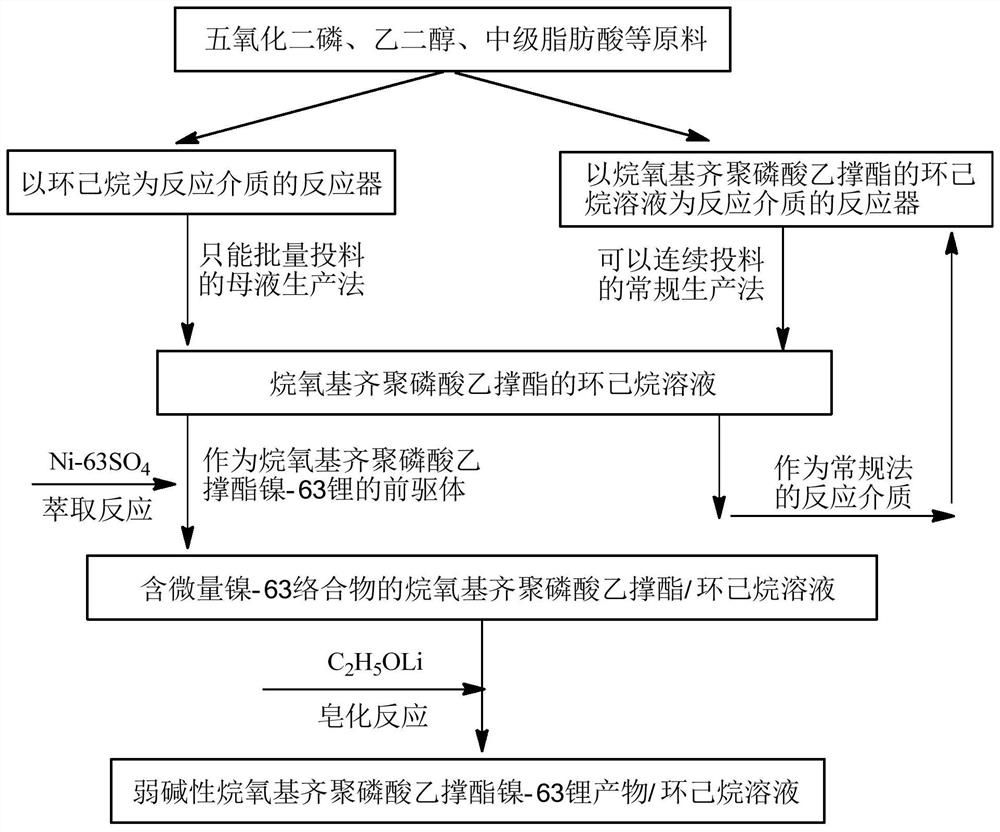

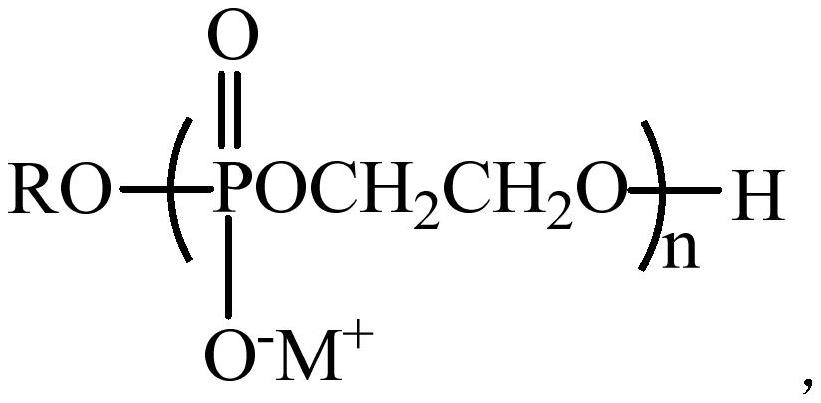

[0062] The second aspect of the present invention provides a method for preparing metal salt of alkoxy oligopolyethylene phosphate, comprising the following steps:

[0063] (1) Using phosphorus pentoxide, ethylene glycol, and intermediate fatty alcohols as raw materials, with the cooperation of reaction medium and feeding auxiliary agents, alkoxy oligopolyethylene phosphate is synthesized by masterbatch method or by conventional methods as Precursor;

[0064] (2) In cyclohexane, using the precursor obtained in step (1), lower aliphatic lithium alkoxide as raw material or the precursor obtained in step (1), lower aliphatic lithium alkoxide, nickel sulfate-63 as raw material, The alkoxy oligopolyethylene phosphate metal salt was synthesized.

[0065] Preferably, the middle fatty alcohol is n-butanol, n-hexanol or isooctyl alcohol, and the lower fatty lithium alcohol is lithium ethoxide and / or lithium methoxide.

[0066] In the synthetic reaction of alkoxy oligopolyethylene pho...

Embodiment 1

[0122] Embodiment 1, the preparation of 375 grams of small samples of isooctyloxy oligopolyethylene phosphate cyclohexane solution used as reaction medium masterbatch

[0123] (1) In a Φ-130mm porcelain mortar as a reaction vessel, add 200 grams of cyclohexane as a reaction medium, and use nitrogen as a protective atmosphere to prevent moisture absorption on the surface of the reaction medium;

[0124] (2) drop into 24.8 gram ethylene glycol liquids in the reaction medium in the Φ-130mm porcelain mortar, stir into turbid liquid;

[0125] (3) In the 150mL glass syringe of the second reaction raw material component, add 50 grams of cyclohexane as a reaction medium, add 0.2 grams of di-isooctyl phosphate as a lubricant, and then add 28.4 grams of phosphorus pentoxide powder Shake to ensure that the phosphorus pentoxide powder is completely wetted by cyclohexane to form a slurry.

[0126] (4) Keep the turbid liquid in the Φ-130mm porcelain mortar reaction vessel in the step (2) i...

Embodiment 2

[0134] Example 2, the preparation of a 375-gram sample of the precursor isooctyloxypolyethylene phosphate cyclohexane solution

[0135] (1) In the 120mL glass syringe of the first reaction raw material component, add 50 grams of reaction medium pure cyclohexane, then add 24.8 grams of first reaction raw material pure ethylene glycol, shake to ensure that it is an emulsion, Duplicate 6 glass syringes containing a mixture of ethylene glycol and cyclohexane;

[0136] (2) In the 120mL glass syringe of the second reaction raw material component, add 60 grams of pure cyclohexane as the reaction medium, and add 1 gram of lubricant, which is obtained from the acidic isooctyl oxide in step (10) The cyclohexane solution of ethylene oligopolyphosphate, then add 28.4 grams of phosphorus pentoxide powder as the second reaction raw material, shake to ensure that the phosphorus pentoxide powder is all wetted by the cyclohexane solution and become a slurry, copy 6 Glass syringes containing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com