Rapid preparation method and application of few layer MXenes

A fast, solution-based technology, applied in the field of rapid preparation of few-layer MXenes, can solve the problems that the advantages of MXenes two-dimensional materials cannot be fully utilized, it is not a good choice, and the preparation process is time-consuming and laborious, so as to reduce the lyophilized solution , low cost, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

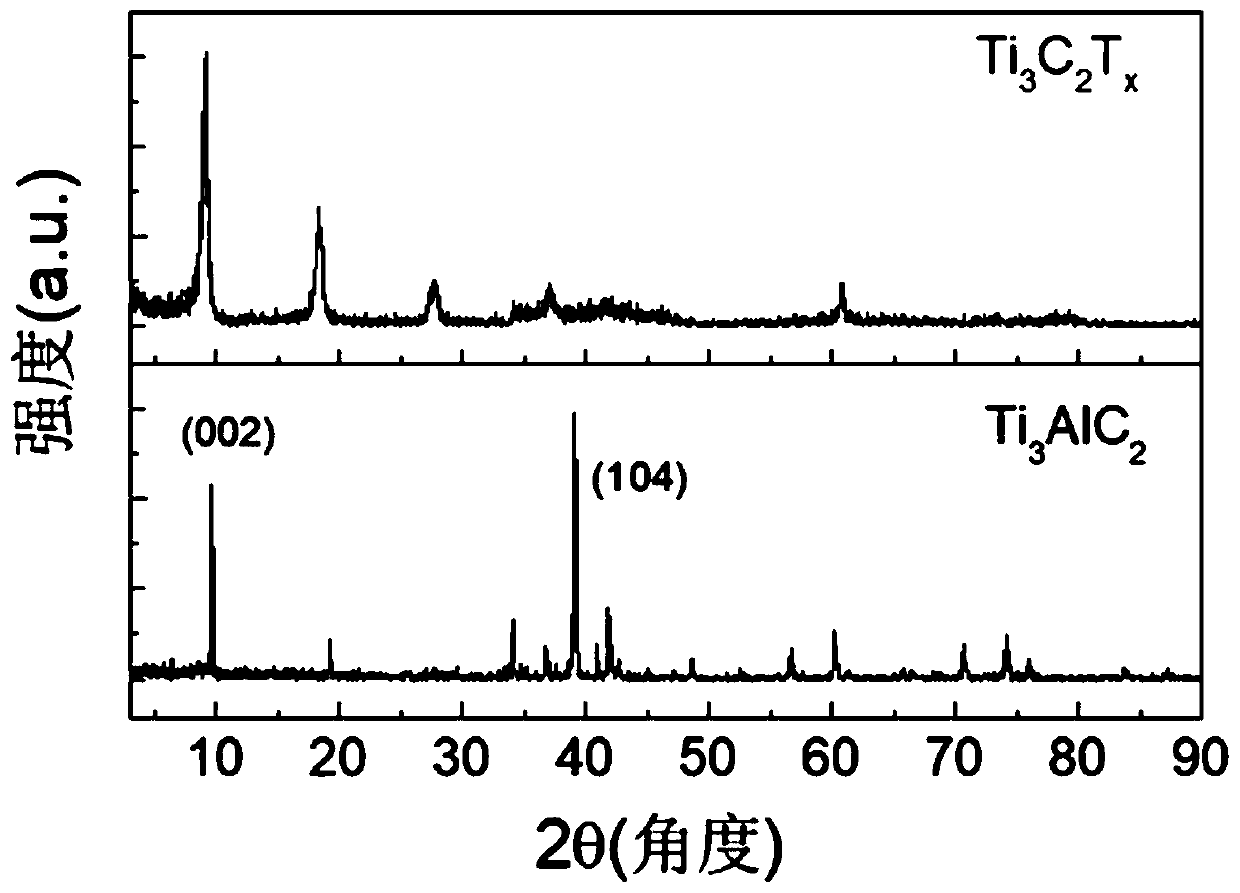

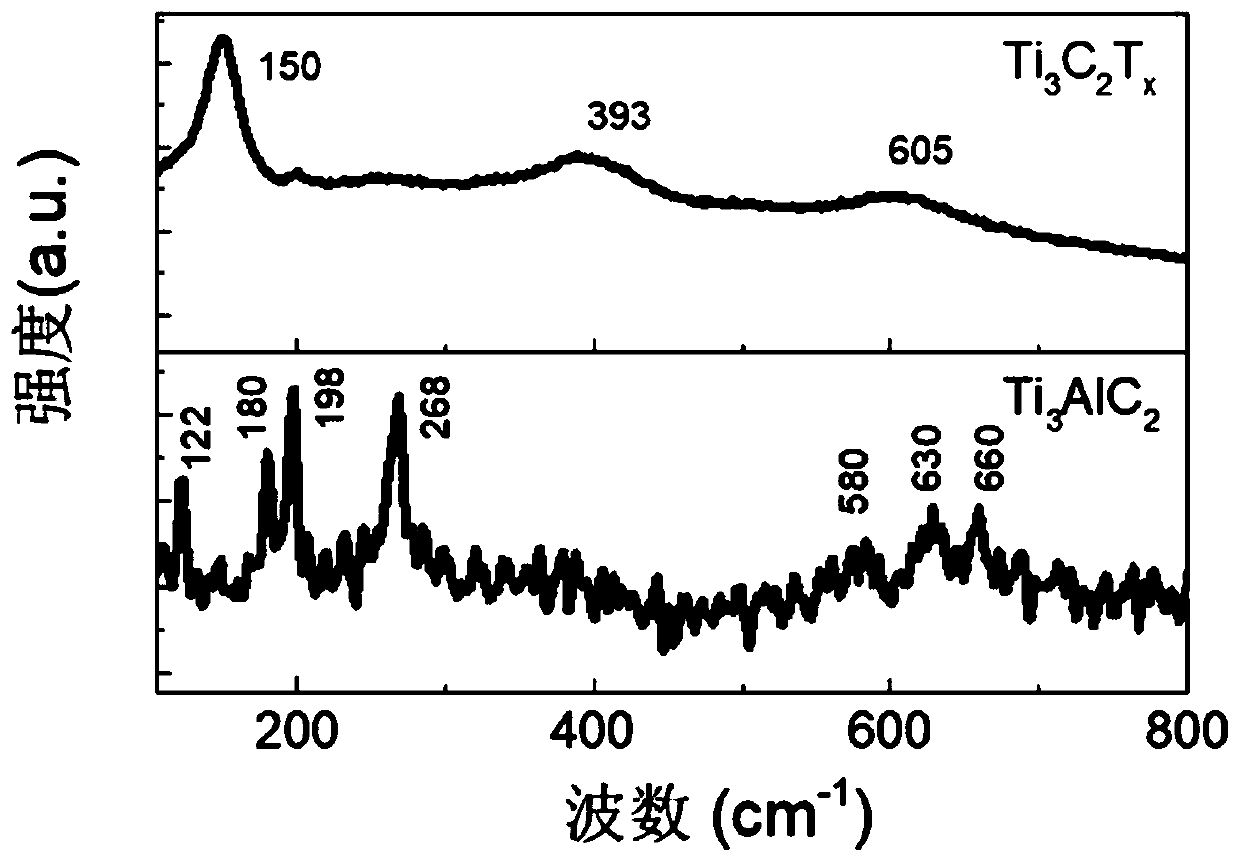

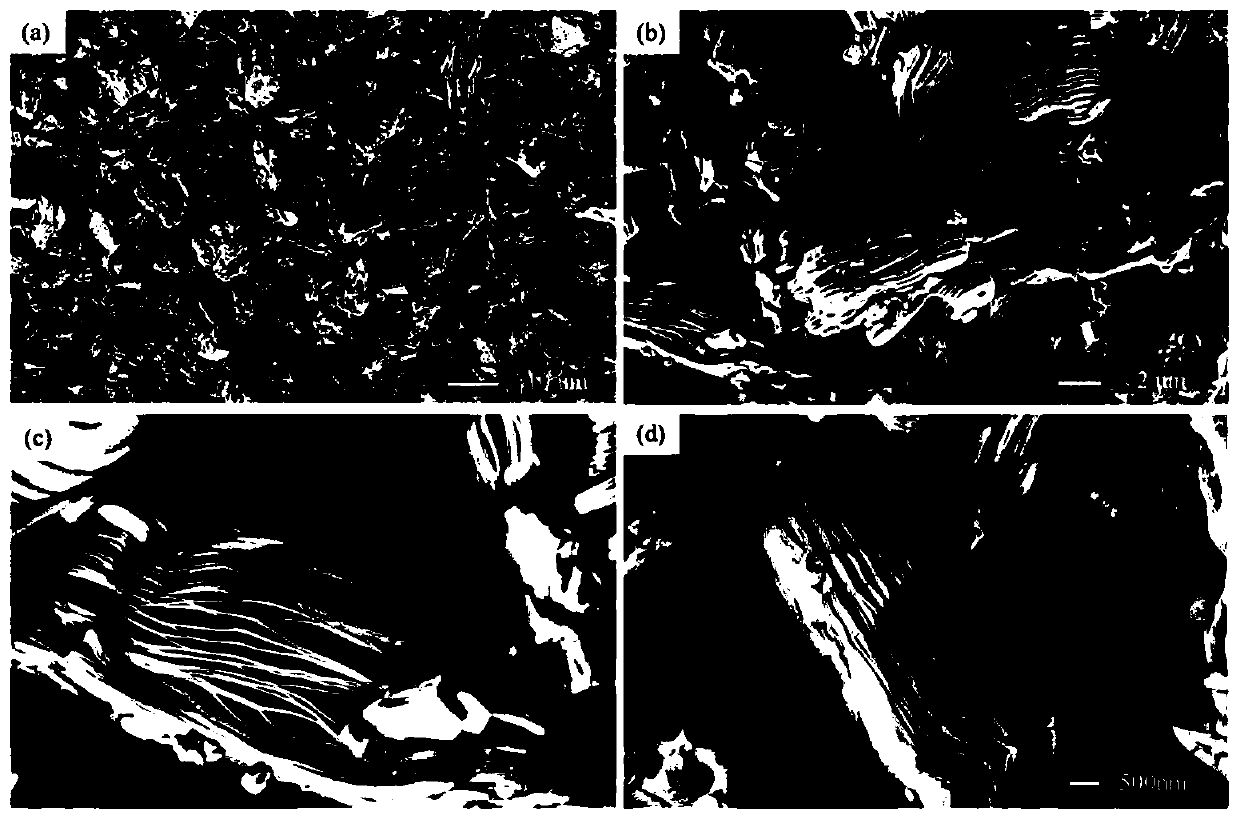

[0041] (1) 10g of Ti with a purity greater than 98% 3 AlC 2 Add ceramic powder to 100ml 40wt% HF solution, stir at room temperature for 48h; then centrifuge and wash with deionized water until the pH value is about 7, freeze-dry the precipitate after centrifugation, and then vacuum dry to further remove Moisture in the material, the drying temperature is 70°C, the drying time is 12h, and the dried material is ground and collected to obtain a multilayer structure Ti 3 C 2 T x MXenes material.

[0042] (2) 1g multilayer Ti 3 C 2 T x Add the MXenes material to 10ml of an aqueous solution with a concentration of 25wt% tetramethylammonium hydroxide (TMAOH), and stir for 24 hours at room temperature to allow organic molecules to intercalate into the interlayer of MXenes, increase the interlayer spacing and weaken the interlayer interaction through intercalation force, and then centrifuged to collect the intercalated multilayer Ti 3 C 2 T x The MXenes material was precip...

Embodiment 2

[0049] (1) 10g of Ti with a purity greater than 98% 3 AlC 2Add the ceramic powder to 100ml of 40wt% HF solution, stir in a water bath at 50°C for 12 hours; then wash with deionized water by centrifugation until the pH value is about 7, freeze-dry the precipitate after centrifugation, and then vacuum Drying to further remove the moisture in the material, the drying temperature is 70°C, the drying time is 12h, and the dried material is ground and collected to obtain a multi-layered Ti 3 C 2 T x MXenes material.

[0050] (2) 1g multilayer Ti 3 C 2 T x The MXenes material is added to 10ml of an aqueous solution with a concentration of 25wt% tetrabutylammonium hydroxide (TBAOH), stirred at room temperature for 24 hours, allowing organic molecules to intercalate into the interlayer of MXenes, increasing the interlayer spacing and weakening the interlayer force through intercalation. Then centrifuge to collect the multilayer MXenes material precipitate after intercalation, a...

Embodiment 3

[0058] (1) 10g of V with a purity greater than 95% 2 Add AlC ceramic powder to 100ml 40wt% HF solution, stir in a water bath at 55°C for 40h; then centrifuge and wash with deionized water until the pH value is about 7, freeze-dry the precipitate after centrifugation, and then Vacuum drying to further remove the moisture in the material, the drying temperature is 70°C, the drying time is 12h, and the dried material is ground and collected to obtain a multi-layer structure V 2 CT x MXenes material.

[0059] (2) Add 0.5g of multilayer V 2 CT x Add the MXenes material to 10ml of an aqueous solution with a concentration of 25wt% tetramethylammonium hydroxide, stir at room temperature for 24 hours, allow organic molecules to intercalate into the interlayer of MXenes, increase the interlayer spacing and weaken the interlayer force through intercalation, and then The multi-layer MXenes material precipitate after intercalation was collected by centrifugation, and washed once with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com